Tower of Strength

Automated handling dilutes sheet metal fabrication costs in this shop with lights-out running and quick changes between jobs.

Posted: February 10, 2015

Since 1915, Midland Tank & Ironplate Co. Ltd (MTI; Birmingham, UK) has been producing sheet metal products for a wide range of industries making parts such as heat exchangers, prototype vehicle parts, door components and many architectural metalworking products, including bespoke staging and lighting systems, and the wings for the ‘phoenix’ in the opening ceremony of the 2012 London Olympics.

Originally formed to help with the war effort by making process tanks, the first technology that was offered by the company back then has now evolved and changed beyond recognition into the world of CAD/CAM and manufacturing management systems, ISO quality approvals, CNC punching and CNC laser cutting with automated loading and unloading, as well as robot welding, assembly and painting services.

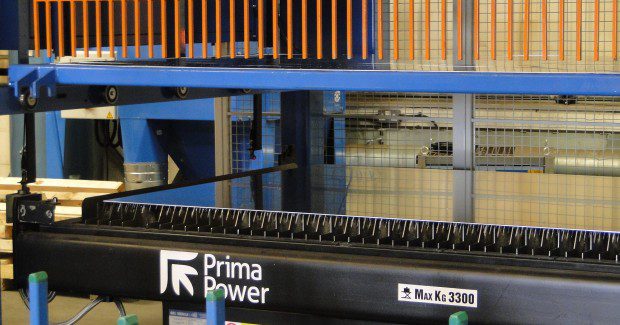

The shop’s laser cutting experience goes back 20 years. It invested in its first Platino® CO2 laser from Prima Power UK Ltd (Coventry, UK) in 2007 and a second Platino® fiber laser in 2013. Both machines are fitted with Compact Tower integrated material handling and storage tower systems.

http://youtu.be/W3tHn70yjk8

http://youtu.be/_EJIantwhBM

Geoff Cox, the managing director of MTI, says, “We needed a bigger, faster and more powerful laser, which drove our investment in the 4 kW Platino CO2 machine with the Compact Tower. Automated handling is an essential part of the system, as it enables us to work unmanned, running batches of material of up to 3 tons. We have CCTV cameras on each machine and a system which alerts the operator by phone should the machine stop out of hours. He can then return to the factory to correct the problem, which keeps production on track and minimizes our labor costs.”

As part of the ongoing maintenance, Prima Power trained MTI engineers in maintenance procedures for the CO2 laser. “UK service has been very good and, with extra training, we now know how to take the optics apart and clean all the lenses and mirrors ourselves,” notes Cox. “This makes a big difference to the performance of the machine as the operator can recognise the signs of a falloff in cutting capability and carry out maintenance and adjustment himself, ensuring that we are always operating at peak levels, with minimum interruption to production.”

Cox realized the speed advantages he could achieve for thin material with a fiber laser. “The wavelength is about 1/10 of a CO2 laser and there are no problems associated with the distribution of the laser power, making it simple and robust,” he says. “Both the pierce times and the cutting times are much faster than CO2 and the shorter wavelength makes it possible to cut brass and copper.” By combining its Radan programming system and e2i process management with the Platino fiber laser, the shop is able to offer very short lead times. For a recent job, the customer required 20,000 parts at the rate of 1,000 per day. MTI was able to deliver the first batch within six hours of the order.

Again, the Compact Tower material handling and storage system makes a big difference to productivity. With up to 15 pallets in one tower, a range of different materials and finished sheets can be stored ready for processing or further operations. While the parts are being laser cut the Compact Tower positions the next sheet on the waiting sliding table. Once the first sheet is finished, the tables switch over to minimize idle time, then cutting restarts and the completed sheet is stored in the tower.

“With this fiber we could choose which side to place the Compact Tower, which was important for our factory layout,” explains Cox. “Now we process thick material on the CO2 and thin material below about 6 mm on the Platino fiber. We can cut thick material on the fiber, but there is not necessarily any speed advantage.”

Because MTI offers its customers a complete service, investment in technology to reduce labor and increase flexibility is in line with its objectives. “Accuracy from the lasers ensures high quality parts, but it is also essential for successful assembly by our robot welders. Automated handling allows us to run out of hours, quickly change between jobs, and dilute costs with overnight running and, because the majority of parts go through these machines, reliability is paramount. We like the service engineers and they respond quickly, involving experts from the Product Unit in Italy when necessary, to make sure any problems we have are resolved quickly and effectively.”

The Prima Power Group offers a complete range of equipment for the sheet metal industry. With over 30 years of experience, it has over 10,000 machines installed in more than 70 countries and has manufacturing facilities in Italy, Finland, the U.S. and China, offering sales and service through a worldwide network of Group companies and distributors. Its range of machinery covers bending, punching, punch-shear, laser, combi and FMS. Automation through automatic loading and unloading, transfer between stations and buffering are highly important for modern productivity. The Group can provide a range of solutions and software systems tailored to suit manufacturer’s requirements, even for the most complex applications.

Midland Tank & Ironplate Co. Ltd., Heneage Street, Birmingham B7 4LY, United Kingdom

+44 121 359 4377, mti.uk.com.

Prima Power UK Ltd, Unit 1 Phoenix Park, Bayton Road, Coventry CV7 9QN, United Kingdom, +08 44 499 6241, paul.downs@primapower.com, www.primapower.com.