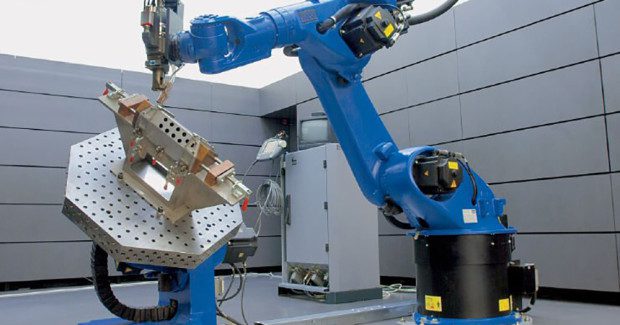

Welding Automation

Here are some of the new automation solutions that are helping shops make their welding operations more productive and profitable.

Posted: February 27, 2015

SMART WELDING TORCH FOR ONE OR TWO WIRE ELECTRODES AND JOINING PROCESSES

Welding with two different filler materials on the same component in one pass and one setting is a task handled by the Wire Select torch system from SKS Welding Systems GmbH (Kaiserslautern, Germany) in a perfect way. The same is true for joining with two different arc-based processes, such as welding or soldering. Both have the potential to achieve significant cost and time savings by replacing systems that rely on the change of the torch or a second welding robot largely from standard components. Only the Y-shaped torch body represents a proprietary component. The torch neck and wear parts come from the standard accessories shelf.

Significantly different temperature conditions in a component, such as at the hot and cold end of an exhaust system, require different materials and therefore also appropriate weld filler materials. High temperature resistant chromium-nickel steel, for example, would require the ferritic wire electrode 1.4511; for low-alloy steel, the austenitic wire type 1.4370 would be the right match. Instead of feeding the different wires via a torch change system or installing a second robot, selecting a Wire Select welding torch would be the smart choice. Within a few seconds, automatic wire change takes place in four short steps: cut, retract, feed, cut. The torch neck taken from SKS’ standard range of products ensures good accessibility to the welding joint.

Combinations of processes are handled by the Wire Select system in the same way. For instance, users can first weld thin steel pipes of hydraulic brake systems and then solder the pertaining brackets. And, of course, for each wire electrode, different gas types can be selected depending on the process and material. The Wire Select weld package is characterized by two hardware components. Number one is the Y-shaped torch body mounted on the Power Clutch collision protection; number two is a second standard wire feed unit including a torch cable. Another additional feature is the separate wire cutter. Users can choose their power source and controller from SKS’ modular standard program.

The advantages of the Wire Select system arise both in comparison to a torch change system and to the installation of a second robot. The investment cost of both of these options is significantly higher. And they come along with indirect financial expenses and downtimes. The tool changeover with the torch change system takes much longer than with Wire Select. Solutions with two robots need more production space, in some cases also additional clamping devices or involve higher positioning and handling efforts. The modular design of SKS Weld Packages provides a high level of flexibility for the user and significant savings for the investor. By replacing the special Wire Select components by other standard components of our program, it is always possible to configure one of the common single-wire welding systems.

In related news, automotive supplier Johnson Controls GmbH & Co. KG Lahnwerk (JCI; Dautphetal, Germany) has managed to eliminate a bottleneck in welding processes on specific joints in car seat structures by using the SKS Power Clutch torch system for components such as SGR tubes and brackets. “After switching to welding systems with SKS torches, we have achieved our defined objectives and even some unforeseen positive add-on effects,” explained Viktor Werz, a manufacturing engineer at JCI. “The seams meet our quality standards, the welding speeds are now higher, and the cycle times shorter.”

At their Dautphetal facility, JCI manufactures high-quality car seat structures. With the solution for the steel connection based on S420 MC tubes, JCI engineers have found a smart way to combine high-tech electronics and mechanical/constructive creativity. The specifics of the SGR tubes and brackets are characterized by a special stereometric position of the parts to be joined: the diagonally cut-off end of a 38 mm diameter tube is led through a round extended and beaded cutout of a metal pressing with a thickness of 3 mm and then welded to it.

To move along the seam contour on the non-planar surface the welding robot needs a reference point to start from. Any position deviations of each individual part – that might occur, for example, due to manufacturing tolerances – must be determined and compensated for. The conventional determination of the reference point involved the risk of errors and additional costs after each change of a gas nozzle. And there were also other drawbacks: The torches were deformed by heat stress and had to be realigned, and the system had to be reset in a time-consuming manner.

The SKS solution eliminates these shortcomings by dealing with the cause: an annular circumferential ridge on the retaining head of the torch now defines a reference position that is independent from the gas nozzle. The “workpiece search” function uses this ridge. A test voltage is applied to the retaining head. Upon contact of the ridge with the workpiece, the robot controller receives a corresponding message and calculates a robot path that is adapted to the position of the workpiece in each case.

Because of the low exchange tolerance of ± 0.2 mm of accessories and consumables, the high TCP (Tool Center Point) accuracy of the torch is maintained during each changing cycle. “We now have extended tool life and also higher welding speeds. The result is a reduction in cycle time of twelve seconds per cycle,” noted Werz. The production department is now sorting out only one faulty part per shift – instead of seven that were recorded before the changes were implemented. The reason for this positive development: the weld spatters including any adverse effects occurring with the previous solution were almost completely eliminated.

SKS North America, 2040 Austin Drive, Suite B, Troy, MI 48083, 248-519-5079, Fax: 248-519-5080, jcolosimo@sks-welding.com, www.sks-welding.com.

ROBOTIC AIR-COOLED MIG GUNS

Responding to the demands of customers’ evolving welding needs, Tregaskiss (Windsor, ON) has introduced the third evolution of its TOUGH GUN™ Robotic Air-Cooled MIG Gun product line: new TOUGH GUN CA3 and TOUGH GUN TA3 Robotic Air-Cooled MIG Guns that bring together the top features of TOUGH GUN G1 and G2 Series Robotic MIG Guns, as well as valuable upgrades to enhance durability, reliability and accuracy.

A new sleek black gun body simplifies identification of the new guns compared to legacy products, but current part numbers will remain unchanged. Both new air-cooled guns feature a re-engineered neck clamp that improves durability and consistency of clamping force, along with additional standard neck options that allow companies to expand the range of tool center points (TCPs) and working envelopes. Additional standard options reduce costs and lead times for special necks and/or arms, while also simplifying the transition from standard TOUGH GUN G2 Series configurations

The TOUGH GUN CA3 Robotic Air-Cooled MIG Gun is a direct replacement for the TOUGH GUN G1 Series MIG Gun that maintains TCP with minimal or no robotic programming touch ups. Designed for conventional robotic welding systems, the new gun also features a new replaceable unicable that promotes extended service life to twice that of standard unicables, reducing costs and downtime for changeover. This benefit is the result of a new dual layer cable; the outer jacket resists ultraviolet radiation and abrasion while the inner layer is specifically formulated to resist thermal fatigue. The copper content of the new replaceable unicable has also been increased compared to standard unicables, allowing for operation at higher current ranges.

Designed for today’s through-arm style robots, the TOUGH GUN TA3 Robotic Air-Cooled MIG Gun is a direct replacement for the TOUGH GUN ThruArm G1 Series MIG Gun and features the exclusive Tregaskiss Low-Stress Robotic (LSR) Unicable, a rotating power connection that allows for stress-free rotation.

Tregaskiss, 2570 North Talbot Road, Windsor, ON, Canada, N0R 1L0, 855-644-9353, Fax: 877-737-2111, info@tregaskiss.com, Tregaskiss.com.

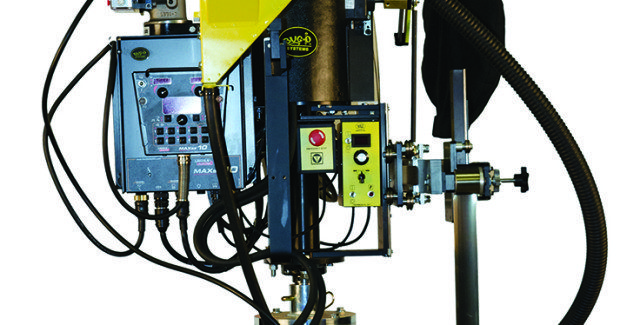

PARTICLE JET TORCH CLEANING STATION

ESAB Welding & Cutting Products (Florence, SC) offers the JetStream torch cleaning station, a particle jet torch cleaning station that cleans consumables with a high velocity blast of granulate. Particle jets clean all torch components (nozzle, tip, gas baffle) and do so without mechanically gripping the torch. The advanced cleaning process extends consumables life, preserves the tool center point (TCP) and maximizes uptime.

Conventional mechanical reamers clamp the torch nozzle, which may deform the nozzle and distort gas flow and affect TCP. With the JetStream station, the torch fits through slits in a silicone seal while the JetStream station sprays abrasive at high velocity for more effective cleaning. No clamping is necessary, preserving the roundness of the nozzle and proper gas flow. When compared to the JetStream cleaning method, a mechanical reamer wears the consumables faster, and the process of mechanically scraping the nozzle and contact tip often has TCP implications. Without the need to scrape consumables clean, consumables last longer and TCP remains intact.

Furthermore, mechanical reamers cannot remove spatter from the gas baffle, potentially leading to gas flow interruptions and inconsistent welds. The high velocity blast of granulate cleans the gas fittings in addition to the nozzle and tip, producing better gas flow and, ultimately, greater weld consistency. JetStream is best suited for high productivity multi-cell environments in thin plate and automotive applications where constant cleaning of the nozzle and contact tip is required. “Users notice that with the improved gas flow, the consumables stay cooler and last longer,” says Jimmy Howell, the ESAB Automation product manager. “They are also observing greater weld consistency due to the optimized gas flow and clean gas fittings. With the mechanical reamer, they could only clean the tip and nozzle.”

Operators also appreciate the time they save at the JetStream station. “They add the abrasive to the hopper and walk away,” notes Howell. “There is no downtime from changing reamer tips. It’s a big time-saver.” The welding area also benefits because the cleaning process produces no surrounding mess. Also, outside of manually cleaning a tandem torch, the JetStream provides the highest quality cleaning system. “On a tandem torch, JetStream offers the only reliable method of cleaning in an automated application,” says Howell.

ESAB Welding & Cutting Products, PO Box 100545, 411 South Ebenezer Road, Florence, SC 29501, 843-669-4411, Fax: 843-664-4258, www.esabna.com.

FRICTION STIR WELD SERVICE FOR SHORT-RUN AND PROTOTYPE PARTS

Coldwater Machine Company (Coldwater, OH), a leading engineering solutions company that manufactures and integrates precision equipment and tools for multiple industries, has announced that its Solid State Joining Center is now providing pre-production, prototype and low volume friction stir weld part production at its headquarters in Coldwater. The company has five Friction Weld Systems (FWS Series) available for use that are all suited for joining like or dissimilar materials including aluminum, magnesium, brass, steel and carbon fiber composites. The five weld systems vary in size and capacity and include robotic automation. Please contact Coldwater for more information.

“We have significant experience in successfully welding a variety of materials with our friction stir weld systems,” said Joining Center director Bob Rich. “As companies are challenged with joining new materials entering the market, they can rely on us as a research and production source, or for the system integration of our technology and equipment into their production facilities, allowing them to better concentrate on their core areas of value.” These friction stir welding solutions are recognized for their cost-effective, repeatable, and robust processes, helping to reduce cycle time and defects when compared to other welding or joining techniques.

Coldwater Machine Company, 911 North 2nd Street, Coldwater, OH 45828, 419-678-4877, www.coldwatermachine.com.