Limited Space, Unlimited Returns

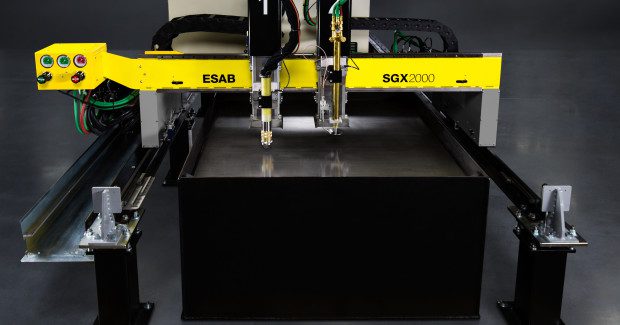

The SGX automated plasma and oxy-fuel cutting machine is ideal for the small fabricator needing to cut high volumes of mild steel parts with a minimal investment in capital and floor space.

Posted: March 3, 2015

Fabricators taking their first step into CNC cutting or smaller shops with a need to cut smaller sheets should consider the SGX automated plasma and oxy-fuel cutting machine. Compact, rugged and easy to use, this system is ideal for small fab shops or manufacturers, some HVAC/blowpipe shops, sign makers, and maintenance shops within larger companies that need plasma cutting, oxy-fuel cutting, and marking capabilities.

RETURNS ON INVESTMENT

Because the owner of these smaller family-owned and operated businesses is often also the programmer and the machine operator on the shop floor, what matters to these fabricators is cutting technology that is simple, easy to use, with a higher level of accuracy that brings new capabilities to their operation. While every shop of any size needs to get the most value for their machinery investment, it’s especially important for the smaller shop because the purchase of a CNC cutting machine can be a significant outlay. For this reason:

(1) A small machine footprint is important. The SGX is engineered to take up minimal floor space relative to the cutting area. All shops need to maximize their production space, and small shops even more so. The SGX gets the most out of every available inch of floor space by being as compact as possible for any given plate size. Machine width is designed to closely match plate width. Rail length is offered in 1 m rail increments for the shortest possible rail system. The SGX covers 1.5 m to 2.5 m (4 ft to 8 ft) wide plate and cutting lengths cover 2.5 m to 6 m (8 ft to 20 ft) plates. Its open floor design means this machine can be used with any type of cutting table, including water and downdraft tables.

(2) The ability to load the machine with a fork truck is important because smaller shops may not have overhead cranes. The SGX takes this into consideration with a low rail design that lets material be loaded and unloaded by fork truck.

(3) The ability to program and nest easily at the machine is important so that no additional investment is necessary in an offline programming system. On the SGX, the machine controller is simple and intuitive to use, making operation easy for even the first-time CNC user. The SGX is built to allow an entry level user or those new to automated cutting to be up and running as quickly as possible. An Operating Wizard provides a step-by-step operating guide that takes the user from file selection to starting the cut. This lets even new operators be productive almost immediately.

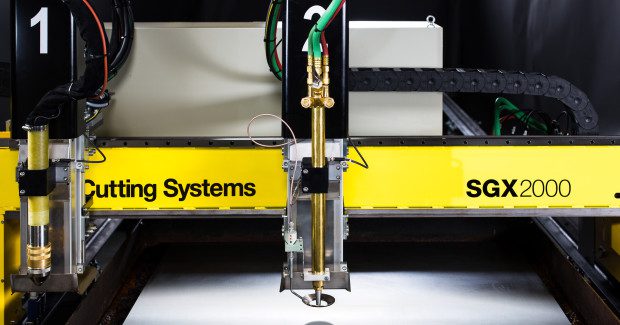

Built-in true-shape nesting automatically optimizes plate utilization. The SGX is equipped with a Vision® T5 CNC that has an easy-to-use touch screen interface and integrated process database to make plasma or oxy-fuel torch setup quick and simple. Making it easier to setup and operate the machine translates to more productivity and less reliance on the operator to achieve good cutting results.

(4) The heavy steel beam construction on the compact SGX is rugged so it can be relied on to cut accurately and be durable, which is vital to a small shop. Its high speed drives and motion systems have been extensively tested – for millions of cycles – to ensure reliable performance over the long term. Heavy steel beam, precision-machined mating surfaces with linear rail deliver smooth motion, consistent accuracy and long service life. The machine’s pedestals are fully adjustable for solid, accurate rail foundation. The precision drive rack mounts directly to the machined rail for perfect alignment. Accuracy over the full cutting area is assured through powerful AC drives and precision planetary gearboxes.

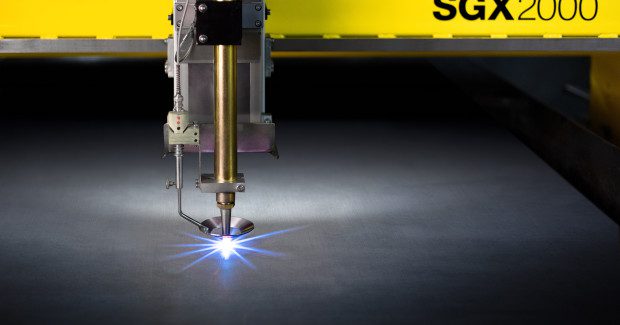

(5) The SGX offers the most advanced cutting technologies. Enhanced Hole Technology™ can be applied to produce high-quality, bolt-ready holes down to a 1:1 diameter-to-thickness ratio in mild steel up to 25 mm (1 in) thick. Smart Voltage Height Control automatically compensates for electrode wear to achieve longer consumable life and more consistent cut quality. By adding Columbus® Software, users can take advantage of SmartCycle™ technology that improves productivity by optimizing cut-to-cut cycle times on nested parts.

The SGX can be equipped with m3 Plasma for precision plasma cutting up to 50 mm (2 in) mild steel, 38 mm (1.5 in) on aluminum, and 25 mm (1 in) on stainless steel. The machine can accept up to two oxy-fuel torches for oxy-fuel cutting of materials up to 100 mm (4 in) thick. Piercing of thicker materials is optimized using ease-on cutting oxygen. A number of optional features allow the user to maximize the machine’s performance, and all of these features are packaged at a price point that puts automated cutting within reach for more users.

APPLICATION PROFILE

The ideal application for the SGX is the small fabricator working with mild steel and needing to produce high volume plasma cut parts with a minimal investment in capital and floor space. The SGX is not the right machine for heavy plate fabricators in steel service center or shipyard applications, or for users who need to handle large plates or produce bevel cut parts.

A potential “ouch” is the shop that needs to cut a wide variety of materials with the highest cut quality. The SGX keeps plasma cost and complexity low by using a fixed plasma shield gas selection. Fabricators who need to use a variety of different shielding gases, or need mixed shield gas options, should instead consider the Combirex machine that can be equipped with more advanced plasma gas control options.

Any investment in plasma automation will pay for itself within a year or two compared to manual cutting methods or outsourced cutting. The SGX provides superior ROI compared to a number of other systems because of its compact size and lower price point