Sawing by the Numbers

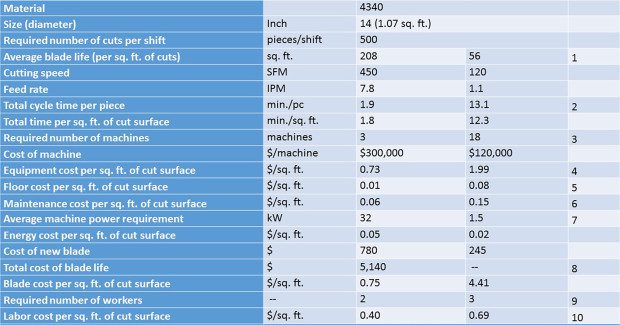

On a cost per square foot of cutting basis, circular carbide saws come out on top.

Posted: March 2, 2015

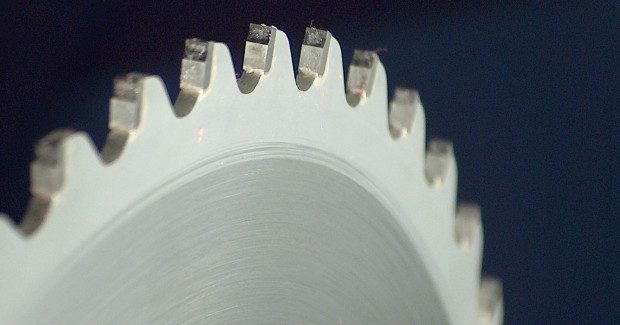

Circular carbide sawing has significant advantages over band sawing when used for high-volume production cutting. However, the advantages of the carbide saw are often obscured by its higher initial purchase price. The accompanying data compares an operation that cuts 500 pieces per shift of 14 in diameter 4340 round steel bar stock using a circular carbide saw and another using a band saw. As Chart 1 shows, the circular saw offers a faster feed rate and cutting speed, with a longer blade life. The circular carbide blades are more expensive, though on a cost per square foot basis, they are more economical because they can be sharpened and reused. When band saw blades wear out, they must be replaced.

Some additional notes on the cost analysis presented in Chart 1:

- Company records show average tool life of approximately 30,000 sq in or 208 sq ft for circular carbide saws and 8,000 sq in or 56 sq ft for band saws.

- Diameter divided by feed rate plus auxiliary time of approximately 0.1 minute.

- Number of machines required based on 500 pieces times total cycle time per piece divided by 384 minutes (based on an eight-hour shift with 80 percent efficiency).

- Total equipment cost equals purchase price plus 3 percent interest over 10 years divided by the usable hours (1,600 hours x 10 years).

- Floor cost per square foot from company records.

- Maintenance cost estimated at 1 percent of machine purchase price.

- Energy cost is based on an empirical value of 0.8 cu in removal of alloy steel per horsepower. Required horsepower equals material diameter times kerf times feed rate / 0.8.

- Total cost of a reusable circular carbide saw blade is calculated at $780 for a new blade, plus four retippings at $330 each, and eight resharpenings per retipping at $95 each, including three replacements for broken teeth. On the other hand, the band saw blade cannot be reused.

- Based on experience, one operator can handle two circular carbide saws, while for slower cutting band saws one operator can handle six saws.

- Total labor cost estimated at $20 per hour.

The stumbling block for many buyers is the upfront cost for a carbide saw, which is two to three times more than for a band saw. But, as this example shows, to handle the same volume of work would require 18 band sawing machines versus just three carbide saws. After totaling up all the relative advantages and disadvantages, the circular saw handles this job at a cost around $2 per sq ft of cut surface, compared to $7.35 for a band saw, according to the data.

There are many different types of cutting machines available to cut many different types of materials, from circular carbide saws and band saws to high-speed steel cold saws, abrasive saws, friction saws, laser cutters and waterjet equipment. Each saw is available in different designs, heavy or light construction, with various head guidance methods such as box ways, linear ways and pivot-type saws. The most complex designs feature hydrodynamic or hydrostatic guides.

In the past, the weight of the machine was a deciding factor for many buyers. The heavier machine was usually the better machine, though it was also higher priced. Tools used by today’s engineers, such as Finite Element Analysis, make it possible to design lighter machines with structural ribbing and vibration dampening that perform very well and at a lesser price. Typically, for general steel cutting, most buyers will end up choosing between a band saw and a carbide circular saw. As the chart illustrates, the choice calls for some careful analysis.

Advanced Machine & Engineering Co., 2500 Latham Street, Rockford, IL 61103, 815-962-6076, Fax: 815-962-6483, info@ame.com, www.ame.com. Advanced Machine & Engineering markets the AMSAW line of sawing machines, material handling equipment and blades.