Tell Them What You Saw

A review of some of the newest sawing systems and related accessories now on the market.

Posted: March 2, 2015

PIPE CUTTING SAW FOR PERFECTLY SQUARE CUTS

An air-powered saw that features a self-centering track system, pre-sized for pipe from 6 in to 60 in diameter, to produce perfectly square cuts with no HAZ (heat affect zone) is available from ESCO Tool Co. (Holliston, MA). The APS-438 Universal Air-Powered Saw features a fiberglass reinforced blade for cutting super duplex stainless steel pipe, concrete lined pipe, ash pipe, and other heavy-wall hard alloy pipe up to 4.375 in thick. Ideally suited for 6 in to 60 in diameter pipe, it is available with the WrapTrack® System of pre-sized stainless steel bands that clamp onto the pipe circumference.

Easy to setup and use, the APS-438 Universal Air-Powered Saw mounts securely onto the WrapTrack® System using a trolley with four V-grooved stainless steel roll guides. Powered by a 3 hp pneumatic motor, the saw is fully supported to reduce operator fatigue. Applications include onsite pipe cutting, erection of piping systems, and pipe fabrication in shops. The APS-438 Universal Air-Powered Saw and WrapTrack® System are priced from $5,895 and up, depending upon the band diameter size.

ESCO Tool Co., 75 October Hill Road, Holliston, MA 01746, 800-343-6926, Fax: 508-429-2811, matt@escotool.com, www.escotool.com.

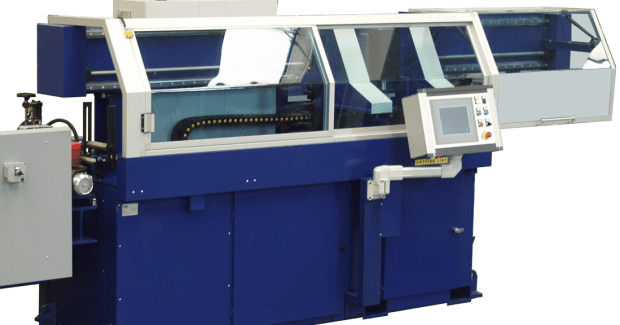

FULLY AUTOMATIC CIRCULAR MITER SAW

The OMP KR3 from Pat Mooney Saws Inc. (Addison, IL) is designed for production sawing applications requiring straight and mitre cuts on bars, tubes and structural work pieces. This machine can replace up to three band saw machines in high production shops, retaining amazing speed and burr-free cut quality. The OMP KR3 uncut design provides a large cutting capacity of 6 in round and 4 in x 8.5 in rectangular ability to cut angles in automatic cycle from 75 deg to the left to 60 deg from the right. The mitre function is fully automatic and allows for multiple angle cuts to be programmed within the same job.

For high speed cutting and extended blade life, several design features are built into the system. The OMP KR3 saw head is hydraulically driven and controlled via servo feed system for precise control of the feed rate. The gear box is equipped with a hydraulic brake to ensure all backlash is removed from the system resulting in longer blade life and allowing for use of carbide or HSS blades. An integrated loading system is available that automatically loads round and square materials into the saw. This system can accept bundles weighing up to 8,800 lb and will load material until the saw program is complete or the saw is out of material. The OMP KR3 can also be equipped with unloading systems configured for specific cut lengths and cutover requirements.

Pat Mooney Saws Inc., 502 S. Westgate Street, Addison, IL 60101, 630-543-6222, Fax: 630-543-5584, info@patmooneysaws.com, www.patmooneysaws.com.

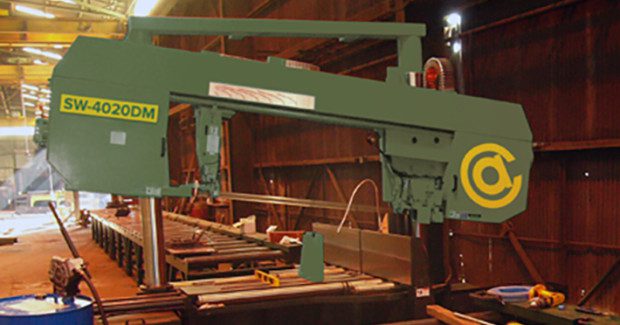

BAND SAW INCLUDES HIGH PRODUCTION OPTIONS AT NO EXTRA COST

Behringer Saws Inc. (Morgantown, PA), a world-class provider of band sawing machines, circular cold saws and structural fabricating equipment, has added more standard features to its HBE Dynamic Series horizontal band saws without increasing selling price. Already economically priced for budget-smart companies, HBE saws now include automatic precision servo down feed control, blade protection sensor technology and other standard features designed to improve cutting rates and throughput, and to reduce downtime.

Owing to improvements in manufacturing methods and advanced component design, company engineers successfully re-engineered the HBE series of saws making a few of the more popular options standard features – at no extra cost. “One of the most popular options is the servo-driven automatic precision down feed control,” said Joe Suydam, a Behringer sales and marketing associate. A sensor-driven cutting pressure control is located at the back of the saw blade. Suydam explained that positioning the sensor directly at the saw blade assures that pressure adjustments are fast and accurate. The control automatically adjusts blade pressure to create the optimum balance between feed rate and blade pressure. “This results in optimum cutting speed with a maximum chip load, and at the same time prolongs blade life,” added Suydam.

Another popular option now included as standard on HBE Series saws is automatic feed control (AFC). The AFC feature automatically adjusts cutting parameters such as blade speed and downfeed rate to the material grade and shape. This permits operators to create flexible material feed programs leveraging cutting data based on specific material grade. Additionally, a fault/alert history may be viewed at any time by the operator. The detailed information displayed in plain text is useful for both planning and analysis of past projects.

Designed for efficiency in high production metal cutting operations, HBE Dynamic Series horizontal band saws are designed to meet a broad range of applications in the steel trade, mechanical engineering, tool making and metalworking shops. The saws utilize a high torque, frequency-controlled blade drive motor. Specialized gearing in the drive results in low power consumption yet produces the blade power and speed needed for fast cutting and peak throughput rates.

The cast iron dual column construction of the HBE saw frame provides the rigidity needed to eliminate stress, reduce vibrations and enhance torsion resistance during cutting. Two linear ways and four ball slides facilitate precise and accurate vertical movement of the blade. Cutting accuracy is further enhanced by the horizontal band arrangement and hydraulically tensioned, double-sided linear guide bearings for the band wheels.

The HBE Dynamic saw is available in four models: 261A, 321A, 411A and 511A. The HBE-261A does not include the standard features upgrade. HBE cutting range is from 10.2 in to 20.0 in diameter for round stock and from 11.8 in x 10.2 in up to 20.0 in x 20.0 in for flat stock. Stroke length is 25.6 in with exceptional tolerances controlled by an electrically powered ball screw driven material feed gripper. Blade speed ranges from 50 fpm to 350 fpm.

Behringer provides a full range of sawing and turnkey pre- and post-cut material handling productivity-enhancing products to corporations, service centers, job shops and manufacturers throughout the world. Their Behringer Eisele brand includes manual, semi-automatic and automatic miter circular cold saws, high performance circular cold saws utilizing bi-metal or carbide saw blades and CNC miter circular sawing systems. Their Vernet Behringer line of structural fabricating equipment includes high performance drilling, punching, shearing, notching and marking machines along with beam coping and drilling and sawing lines.

Behringer Saws, Inc., 721 Hemlock Road, Morgantown, PA 19543, 610-286-9777, Fax: 610-286-9699, www.behringersaws.com.

GENERAL PURPOSE SAW WITH SHUTTLE VISE

The all-new 400AV general purpose band saw from Continental Machines Inc. | DoAll Sawing Products (Savage, MN) is one of DoALL’s introductory machines in the growing StructurALL family of saws. Featuring automatic indexing with an all new servo-driven ballscrew shuttle vise, pneumatic head lift and hydraulic feed control, the 400AV is the ideal machine for a small to medium fabricator or machine shop looking to make extremely accurate straight cuts in smaller quantities.

Featuring a 10 in high x 16 in wide capacity for rectangles and 10¾ in rounds at 0 deg, this machine can be equipped with a variety of options to further ease operation such as gravity roller conveyors and vertical guide rollers. If you’re looking for an economical, general-purpose saw to meet your needs without straining your budget, check out the all-new 400AV!

Continental Machines Inc. | DoAll Sawing Products, 5505 West 123rd Street, Savage, MN 55378-1299, 952-895-6427, www.doallsawing.com.

LINEAL CUTTING PRODUCTIVITY, ACCURACY AND PORTABILITY

SawGear, the highly portable, automatic lineal cutting system made by TigerStop, LLC (Vancouver, WA), has added jobsite tables to its product line. The tables are available in 8 ft, 12 ft, and 16 ft working lengths, and users can add on in-feed tables made to customized lengths for added convenience. SawGear now comes standard with a feature called Crown+MiterPro, which instantly calculates difficult crown angles and lengths, making the entire product offering an on-site solution for increased productivity while providing shop-accurate results.

http://youtu.be/viel1Df0Nsc

“With the tables to support your materials throughout their length, you are guaranteed accurate cuts every time,” says company founder and president, Spencer Dick. “SawGear with Crown+MiterPro and the new tables helps a shop control most cutting variables and eliminate a huge portion of human error, so you’re increasing your yield from your raw materials as well as increasing the accuracy and quality of the work that’s done.” The design of each table incorporates a hinge system and tripod supports, making the tables easily transportable, simple to level and quick to set-up and break down. Also available are customizable in-feed tables.

SawGear easily attaches to either side of a miter or chop saw, providing automatic and accurate length measuring on the jobsite. Because lengths are simply entered into SawGear’s keypad, the need for repeated measuring is eliminated, saving time, reducing material waste and vastly increasing efficiency. From framing to finish carpentry, this easy-to-use technology improves the accuracy of every cut to within 1/128 in. The entire system sets up in minutes, fits on either side of the saw, can store up to 100 cut dimensions, and includes an anti-theft feature which makes the tool useless to thieves as well as an anti-pinch safety system.

TigerStop is a global leader and U.S. manufacturer of automated stop/gauge and pusher systems for metalworking, construction and other applications.

TigerStop, LLC, 12909 NE 95th Street, Vancouver, WA 98682-2426, 360-254-0661, Fax: 360-260-0755, www.sawgear.com.