Tell Them What You Saw

A review of some of the newest sawing systems and related accessories now on the market.

Posted: March 2, 2015

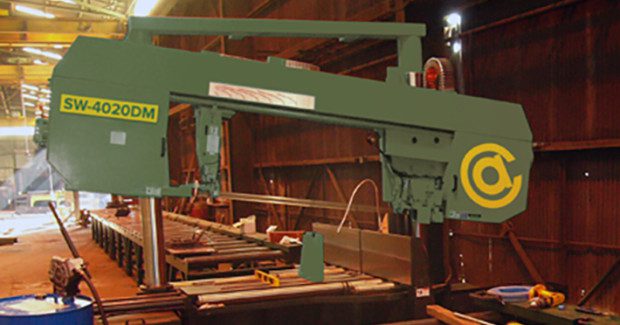

LARGE CAPACITY SAWS FOR STRUCTURAL STEEL FABRICATION

The SW5120DM is a 51 in x 20.5 in (520 mm x 1300 mm) heavy duty miter band saw from Controlled Automation, Inc. (Bauxite, AR) is perfect for pairing with CNC drilling and punching lines. This large heavy duty miter saw (60 deg both directions) is designed specifically for the structural steel fabricator, with features that include a robust heavy design of over 18,000 lb, a 10 deg blade cant, a larger 2.625 in (67 mm) band saw blade that is powered with a 20 hp motor for faster accurate cuts beyond most heavy structural saws, and a large specially designed planetary gearbox.

An optional Automatic Saw Measuring system is available and, when combined with a Controlled Automation rack & pinion probe system that uses Miter Multing through SICAM software, it achieves the best in material utilization and inventory feedback. Standard on all of these model saws is a Chip Auger that removes chips from the cutting area into an easy-to-empty container. This saw uses exceptionally large diameter band wheels of a hardened casting to provide unsurpassed band wheel life and extended blade life.

For straight cuts, the large 40 in x 20.5 in (520 mm x 1020 mm) SW4020-S Double-Column Structural Saw is also perfect for pairing with CNC drilling and punching lines. It has a robust heavy design of over 11,000 lb, a 7.5 deg blade cant, and a large specially designed planetary gearbox. It uses a large 2 in (54 mm) band saw blade that is powered by a 10 hp motor for fast accurate cuts beyond most heavy double-column saws.

This saw uses a standard Chip Auger to remove chips from the cutting area into an easy-to-empty container and has exceptionally large diameter band wheels of a hardened casting to provide unsurpassed band wheel life and extended blade life. An optional Automatic Saw Measuring system can be combined with a Controlled Automation rack & pinion probe system that uses Miter Multing through SICAM software for the best in material utilization and inventory feedback.

Controlled Automation, Inc., 15701 West Sardis Road, Bauxite, AR 72011, 501-557-5109, www.controlledautomation.com.

CARBIDE BAND SAW BLADE FOR AEROSPACE ALLOYS

LENOX® (East Longmeadow, MA), a leading manufacturer of premium power tool accessories, hand tools and band saw blades, offers the MAX CT™ carbide band saw blade in answer to the stringent needs of the growing aerospace market. Designed to provide increased blade life, faster cutting and superior part finish over traditional band saw blades, the MAX CT offers high performance in a range of applications to solve industrial manufacturers’ needs for higher productivity. With advanced blade design, innovative tooth geometry and next generation welding technology, MAX CT provides a quality solution for improved cutting performance on hard to cut metals, resulting in longer blade life and faster, straighter cuts, which translates to fewer changeovers and less downtime.

“From our research we learned that the most important factors of blade quality for users are longer blade life, increased cutting speed and superior part finish. In response, we created MAX CT to answer the needs of the expanding aerospace market segment and deliver precision cutting on traditionally hard to cut materials,” said Daniel Fernandes, a product manager at LENOX. “In testing, MAX CT produced more cuts per blade than its closest competitors, delivering on our goal to provide products that help lower the total cost of operations.”

Designed for precision cutting, MAX CT provides maximum cutting performance of nickel-based alloys, stainless steels, tool steels and titanium alloys. The high rake angles increase the shear plane angle, reducing cutting forces and aiding in tooth penetration. The blade’s next generation welding technology prevents premature tooth loss, providing a stronger bond between the carbide tip and the backing steel, making for longer blade life and faster cuts.

MAX CT features a three tooth pattern that balances the chip load and reduces cutting forces, leading to longer blade life. The new gullet design uses an optimized geometry to reduce concentration of stress risers, delivering straight cuts and extended fatigue life. The blade’s precision ground carbides create razor sharp teeth for a mirror-like finish on cut parts. MAX CT is available in a wide range of blade widths to fit the majority of carbide-friendly band saws.

LENOX, part of Newell Rubbermaid, began in 1915 with ten employees and a passion for building hacksaw blades that cut faster and lasted longer. Now, 100 years later, that passion hasn’t changed, but the team has grown to more than 600 people who manufacture and market products in more than 70 countries. Our ISO 9001-certified facility in East Longmeadow boasts a 500,000 sq ft, 11 acre space for designing, testing and manufacturing power tool accessories, hand tools, and band saw blades.

LENOX, 301 Chestnut Street, East Longmeadow, MA 01028, 413-525-9646, www.lenoxtools.com.

METAL SAWS LEAVE A WORKABLE EDGE & PROVIDE LONG BLADE LIFE

Fein Power Tools, Inc. (Pittsburgh, PA) has three new Slugger saw models: two redesigned Slugger metal cutting hand saws in 7.25 in and 9 in blade sizes, and an upgraded 14 in Slugger metal chop saw. All three are designed to perform best while using Slugger metal saw blades that provide significantly longer life than disposable composition blades. These versatile saws are high quality power tools, well suited for work in the shop, on the jobsite or anywhere power is available.

The 7.25 in saw has a powerful, double insulated 3,800 rpm soft start motor for continuous power. Its electric brake is activated when the trigger is released eliminating blade free-spin and the specially designed blade cover provides integrated chip and spark collection. An internally powered integrated laser guide aides cutting accuracy and eliminates the need to replace batteries. The unit weighs 15 lb (6.8 kg) with a vibration rating of 7.20 sq mps. The 9 in redesigned metal saw has a 15A, 1,800 W, 2,300 rpm motor with a worm gear drive. It weighs just 21 lb (9.5 kg) with a 7.20 sq mps vibration rating and can be used for plunge cuts. It shares all the other same features of the 7.25 in model saw with the addition of an on-board work light.

The upgraded 14 in Slugger metal chop saw is a high-performance portable unit having a clamping saw table with a table mounted vise for safety and fast, accurate cuts no matter what shape metal is being used. Its 1,800W, 15A motor delivers 1,300 no-load rpm and weighs 54 lb (25 kg). It features a double trigger safety start and a spring loaded split guard face, electric brake to eliminate blade free spinning and an integrated chip collection tray. The unit also provides a clear view of the work being performed.

These saws provide several advantages over competitors. Slugger saws leave a workable edge when cutting steel plate, angle, pipe and square or round tube while making straight or bevel cuts up to 45 deg. The chop saw can also easily handle round and square stock plus threaded rod. The company recommends that all these new metal saws be used with Slugger metal saw blades that are designed for fast and accurate cuts. The blades are cooler cut surface because the heat is transferred to the cut chips. Slugger blades are also more accurate and maintain a constant diameter throughout the cut.

Fein, founded in 1867, invented the first power tool — the electric hand drill in 1895 — and holds approximately 500 patents and patent applications, with products that are distributed worldwide through 19 international subsidiaries.

Fein Power Tools, Inc., 1030 Alcon Street, Pittsburgh, PA 15220, 412-922-8886, www.feinus.com.

VACUUM PANEL SAW CUTS 16 GA STEEL

The KSV-434 Vacuum Panel Saw from Kett Tool Company (Cincinnati, OH) provides a safer, cleaner environment for contractors and manufacturers who need to cut construction panels. This Vacuum Panel Saw uses a 5 amp, variable speed motor and accepts 2.5 in blades for cutting cold-rolled mild steel up to 16 ga or laminate panels. It is also capable of cutting 5/8 in drywall, fiberglass, plastic sheet and other construction panels. The saw features a spring-loaded blade guard for added safety. Its 3.5 in carbide abrasive or high-speed steel saw blade can perform cuts up to 1.0625 in deep.

http://youtu.be/m3R_RSzZbpU

Cutting construction panels with a standard circular saw produces a large amount of airborne dust, which creates an unhealthy work environment and requires extensive clean-up. This Vacuum Panel Saw uses a cast aluminum vacuum head that connects to a canister vacuum or in-plant collection system, collecting the dust generated by the saw before it can become airborne to reduce inhalation hazards and clean-up time. The KSV-434 Vacuum Panel Saw is available through authorized dealers located in every state in the U.S. Kett is celebrating 75 years of producing electric and pneumatic portable power saws, shears and nibblers that cut a wide range of sheet material used in various applications.

Kett Tool Company, 5055 Madison Road, Cincinnati, OH 45227, 513-271-0333, www.kett-tool.com.