What’s New in Coordinate Measuring Machines

Here are some of the latest technologies that are bringing new capabilities to CMM applications.

Posted: March 5, 2015

The TCR20 is a compact probe module rack for use with PH20 that provides the capability for quick and repeatable tool changing and tip correction based on the MCR20 rack systems. It securely stores modules for rapid automatic changing and protecting mating surfaces from any airborne contaminants within the working envelope of the machine. The TCR20 supports the full range of TP20 modules which are compatible with the PH20 system and features an integrated tip datum artifact in the center of the rack assembly, minimizing the cycle time of the tip correct procedure.

The company also offers the STRATO-Apex574 coordinate measuring machine as part of its STRATO-Apex line of CMMs. This configuration comes in a more compact footprint while still offering the same state-of-the-art blend of high-speed operation and highly accurate measurement. The STRATO-Apex574 is a compact bridge-type design featuring accuracy as low as 0.7 µm. It utilizes a 0.05 µm resolution scale and temperature range of 18 deg C to 22 deg C (64.4 deg F to 71.6 deg F). This CMM is ideal for manufacturers who produce high precision small parts for industries such as medical, precision mold, and aerospace that require a smaller footprint for CMM inspection.

The STRATO-Apex line offers high speed and accuracy in measurement that is ensured by a specially designed machine body that has improved rigidity of the structure, a precision guide mechanism, ultra-high precision crystallized glass scales with near-zero thermal expansion and the incorporation of newly developed compensation technology. A standard vibration-dampening unit is included as a standard accessory to round out this CMMs advanced capabilities.

The STRATO-Apex line features dual joysticks, air balanced Z-axis ram, precision air bearings on all axes, a USB, fully digital DC 32 bit Mitutoyo CNC CMM Digital Signal Processor controller with a PH10MQ quill mounted probe head featuring internal wiring. A wide range of inspections solutions including scanning probe, non-contact laser scanning, video, and surface roughness inspection can be added to ensure versatility that will satisfy almost any inspection need.

Mitutoyo Corporation is the world’s largest provider of measurement and inspection solutions offering the most complete selection of machines, sensors, systems and services with a line encompassing CMMs (Coordinate Measuring Machines), vision, form and finish measuring machines as well as precision tools and instruments, and metrology data management software.

Mitutoyo’s nationwide network of Metrology Centers and support operations provides application, calibration, service, repair and educational programs to ensure that our 6,000+ metrology products will deliver measurement solutions for our customers throughout their lifetime.

Mitutoyo America Corporation, 965 Corporate Boulevard, Aurora, IL 60502, 630-820-9666, Fax: 630-820-2614, info@mitutoyo.com, www.mitutoyo.com.

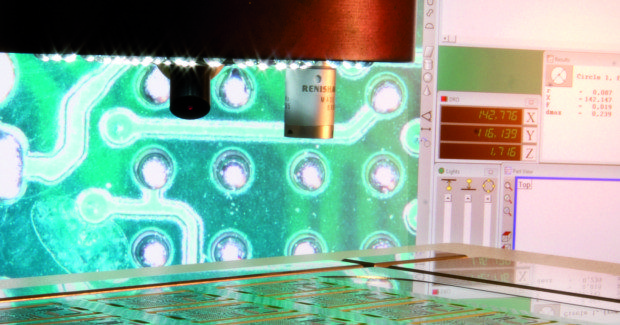

CNC VIDEO MEASURING SYSTEMS

Nikon Metrology, Inc. (Brighton, MI) offers two CNC Video Measuring Systems, the iNEXIV VMA-4540V and 4540. These products offer a wide field of view, easy operation, and allow the measurement of both large and tall mechanical parts. iNEXIV CNC Video Measuring Systems automatically inspect the dimensions of a variety of precision equipment and electric parts, using optical measuring and image processing technologies. By precisely detecting the edges of the sample using CCD camera images and data processing, the measurement of complex sample shapes is possible.

The cost–effective VMA-4540V/4540 is an addition to the iNEXIV series. It offers a larger measurement stroke than the iNEXIV VMA-2520. While The VMA-4540V offers video measurement only, the VMA-4540 additionally provides optional touch probe measurement.

Suitable measuring range for large parts of or multi-part inspection

The large 450 x 400 x 200 mm stage stroke supports the high-speed measurement of large printed substrates and tall plastic-injection-molded parts, and the mass inspection of multiple parts simultaneously, resulting in a significant reduction in inspection costs.

Clear images with wide field of view

A wide Field-of-View (FOV) of up to 13 mm x 10 mm (at 0.35x) makes the search and alignment of measuring targets easy. An excellent Apochromat objective lens with high NA (0.11) and low distortion, designed especially for the iNEXIV series, to provide crisp, clear images. The VMA-4540V/4540 is equipped with episcopic, diascopic and 8-segment ring LED illuminators to suit the sample shape. Combining these illuminators and adjusting light intensity and direction, makes the accurate detection of low contrast edges possible.

Fast and accurate vision Auto Focus (AF)

The VMA-4540V/4540 series is equipped with highly repeatable vision AF that offers high-speed, high-precision focusing of sample surfaces or edges, reference-plane settings and height/depth measurement. Non-contact measurement using vision AF has the benefit; it does not damage or deform parts. Laser AF is available as an option, enabling the height measurement of flat surfaces with high repeatability at any magnification or depth of focus.

Tactile 3D shape measurement (option)

The VMA-4540 is touch-probe ready and can accommodate optional Renishaw® TP20 or TP200 touch probes. Touch probes enable the measurement of 3D parts when video measuring methods are unable to inspect lengths and angles in areas that not visible from above. A single Teaching File captures both video measurements and touch probe measurements into one.

Nikon Metrology, Inc., 12701 Grand River Road, Brighton, MI 48116, 810-220-4314,

marketing.nm-us@nikon.com, www.nikonmetrology.com.