Adjustable Angle Heads for Machining Tricky Angles

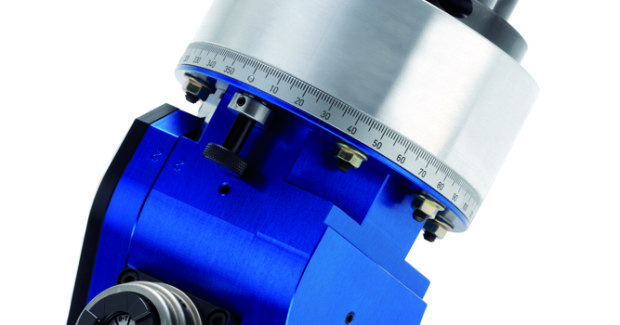

Available in small to large custom sizes, adjustable angle heads from Benz Inc. are engineered for use in general manufacturing and light production operations where the machines need to change angles frequently.

Posted: April 16, 2015

German tooling systems expert Benz Incorporated (Charlotte, NC) has announced that it is now offering new adjustable angle heads to help manufacturers improve their machining and milling operations. Engineered in Germany, these tooling systems are sold and serviced in the United States and Canada from their North American headquarters in Charlotte.

“These adjustable angle heads offer manufacturers an effective solution for enhancing productivity and efficiency,” explained Chuck Shive, the technical services manager at Benz Inc. “Because it can be adjusted to tricky angles, a single adjustable angle head can replace and do the work of multiple tooling heads.”

Available in small to large custom sizes, these adjustable angle heads are engineered for use in general manufacturing and light production operations where the machines need to change angles frequently. A worm gear on the back side of the angle head makes adjustments faster and easier, which reduces down time and retooling time that would otherwise slow down efficiency and productivity.

https://youtu.be/U-3fFCNGKBQ

Benz also produces fixed angle heads including right angle heads for light to heavy production applications that require rigidity. Once in place, these fixed angle heads cannot be knocked out of position. These angle heads have a one-year warranty and are expected to have an average life of three to five years.

Benz Inc., a member of the Zimmer Group, is the technological leader for the production of innovative machining heads for the wood, plastics, composites and metalworking industries. The company manufactures tooling systems in Germany and offers sales and support for the United States and Canada through its subsidiary, Benz Inc., headquartered in Charlotte.

Benz Incorporated, 8325 Arrowridge Boulevard, Charlotte, NC 28273, 704-529-5300 Fax: 704-529-5009, mail@benz-inc.com, www.benz-inc.com.