High Water Marks

A review of some of the latest advances in waterjet cutting technology and related accessories that are now on the market.

Posted: April 28, 2015

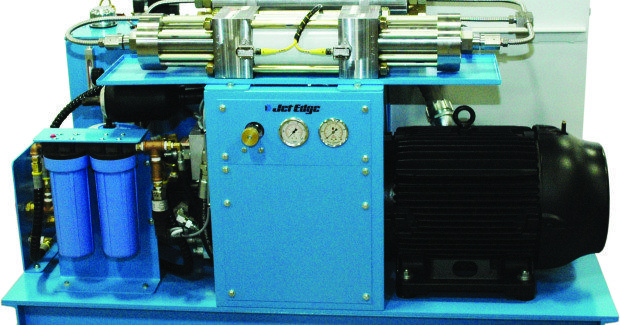

- Increased intensifier flow rate through horsepower

- Variety of choices to meet OEM and customer requirements

- Ultra-High Pressure Intensifiers

- Top Cover Guard Interlock design

- Meets EN ISO13849-1 Safety Performance Standard PLa rating

- Power Factor Correction

- Reduced electrical demand and operating costs

- Onboard Air Cooler

- Reduced monthly water usage

- IE3 and NEMA Premium Motor Design

- Optimized motor efficiency, reduced electrical consumption

- Siemens PLC based electrical panel

- Universal design for global network support

- Redesigned Electrical panel

- Separation of High Voltage and Low Voltage sections to meet NFPA79E and IEC 60204 Standards

KMT Waterjet Systems Inc., 635 West 12th Street, Baxter Springs, KS 66713, 620-856-2151, sales@kmtwaterjet.com, www.kmtwaterjet.com.

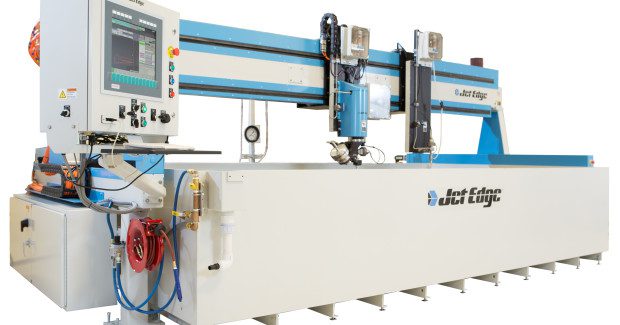

WATERJETS FOR LARGE-SCALE PRODUCTION

OMAX Corporation (Kent, WA) continues to set new standards in abrasive waterjet cutting technology with the expansion of its line of MAXIEM JetMachining® Centers, introducing three larger sizes of its next generation MAXIEM to meet the needs of job shops, OEMs, metal service centers, and other fabricators competing for large-scale production: the 2060, 2080, and 3060 JetMachining Centers. The 2060 and 2080 models are ideal for a wide range of modern large format machining of parts up to 6 ft 7 in wide by 20 ft 6 in long and 27 ft 2 in long, respectively. The 3060 JetMachining Center boasts a wider work envelope that is ideal for machining of a wide range of materials and thicknesses, from metals and composites to glass and plastics. This machine features a Y cutting travel of 10 ft 2 in, more than three and a half feet wider than the 2060, and an X cutting travel of 20 ft 6 in.

The complete MAXIEM lineup continues the tradition of easy-to-use, reliable and efficient abrasive waterjet machines designed and built in the United States. These JetMachining Centers also feature the industry leading Intelli-TRAX® linear drive system that utilizes brushless servo motors, integrated servo drives and high precision linear encoders that provide constant and continuous feedback on the actual position of the cutting head. In addition to increased part cutting accuracy, the advanced drive system delivers much faster and smoother motion. The all-in-one Windows® 8 controllers on the MAXIEM machines come pre-loaded with the powerful Intelli-MAX® Software Suite that makes it easy to generate complex geometries and produce quality parts from virtually any type of material.

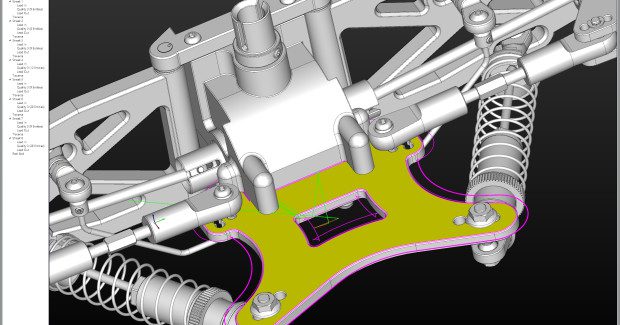

OMAX also offers a highly advanced computer-aided manufacturing (CAM) software tool that further simplifies the cutting of complex, precision parts on its JetMachining® Centers. Free to OMAX owners, the new Intelli-CAM 3 software, which interfaces directly with the company’s intuitive Intelli-MAX® Software Suite, easily generates 3D tool paths from solid 3D models as well as quickly performs 3D to 2D file conversions.

Intelli-CAM, through its 3D Pather tool, quickly generates multi-axis, machine-ready tool paths from complex 3D solid models. In fact, Intelli-CAM automatically recognizes viable cutting surfaces from those 3D shapes, including variable bevels and tilted cones. This special functionality eliminates the need to manually add 3D attributes to a 2D file, thus allowing users to significantly reduce their production times. With its user-friendly and powerful 3D to 2D conversion system, Intelli-CAM generates machine-ready cutting geometry through a few simple computer mouse clicks. With the 3D file imported, users extract the desired 2D profile directly from a slicing plane, shadow or face. Intuitive navigation tools make it easy for users to position and orient the slice – including rotations around all axes, orienting to a face, or projecting as a shadow.

Offered as a free update for existing JetMachining Center owners, Intelli-CAM operates as a standalone application or in tandem with several of the popular third-party 3D CAD systems. It supports a wide range of neutral and native 3D file formats – CATIA, SolidWorks®, Solid Edge, Autodesk® Inventor®, Siemens® NX, Pro/E®, Creo®, Step, IGES, VDA-FS, ACIS, Parasolid®, 3D DXF and DWG – so that customers avoid having to purchase expensive CAD software filter packages. Intelli-CAM also supports direct interface with CAD software such as SolidWorks, Inventor and Rhinoceros®, which allows users to launch Intelli-CAM directly from those applications.

According to Carl Olsen, the lead software engineer for OMAX, Intelli-CAM allows the Intelli-MAX Software Suite to support just about any 3D or 2D CAD file or artistic drawing. “Our job shop customers will greatly benefit from Intelli-CAM as they will rarely ever again have to ask their customers to re-save a file to a format they can accept – because they can now accept nearly all of them,” he said. He also noted that customers doing 3D programming for 5-axis waterjet cutting will find Intelli-CAM 3 greatly simplifies those operations as well, suggesting that Intelli-CAM “may be the easiest to use 5-axis CAM software ever, and it’s free.”

OMAX Corporation, 21409 72nd Avenue South, Kent, WA 98032, 253-872-2300, Fax: 253-872-6190, omax@omax.com, www.omax.com.

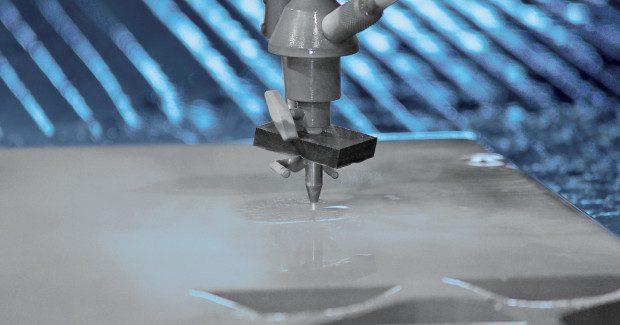

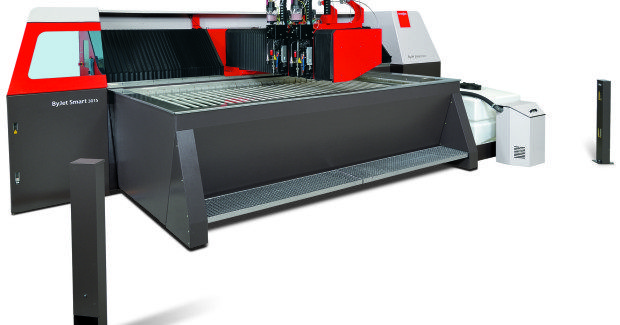

WATERJET SHAPE CUTTING COMBINED WITH PLASMA CUTTING

ESAB Cutting Systems (Florence, SC) offers the Hydrocut™ LX, a waterjet shape cutting machine that combines waterjet and plasma cutting to deliver the best of both technologies. The Hydrocut LX CNC cutting machine uses the patented combination of thermal and non-thermal processes operating on the same gantry, allowing the machine to cut with the high accuracy of waterjet where needed, but employ the high speed and low cost of plasma whenever possible. By combining waterjet and plasma on the same machine, both tools can be used on the same parts. High precision contours can be cut with waterjet, while non-critical contours can be cut with plasma.

This patented system allows users to obtain precise cuts when needed without sacrificing speed on every cut. Parts that are suited for the waterjet-plasma combination can be cut in a fraction of the time, resulting in dramatic cost reduction and productivity increase when compared to waterjet cutting alone. The Hydrocut LX is a heavy-duty gantry with a high-stiffness beam design featuring dual precision linear rails and precision rack and pinion drives. It is designed to cover large working areas and full size sheets, and can be equipped with up to four waterjet stations, and can also carry up to two high-definition plasma stations, featuring the m3 Plasma system.

The Hydrocut LX is equipped with the latest in waterjet cutting technology, featuring KMT 90,000 psi capability for increased cutting speed and reduced abrasive consumption. By increasing the water pressure from 60,000 psi to 90,000 psi the abrasive is accelerated to a higher speed, thereby cutting faster while using less. This helps lower operating cost, because the cost of abrasive can be as much as 75 percent of the operating cost of waterjet. The m3 Plasma system provides high precision cutting on carbon steel, stainless steel and aluminum from gauge material up to six inches thick. The m3 system is fully automated by the Vision® T5 CNC, a Windows® based touch-screen control.

Flexibility in selection and mix of shield gases allows an operator to produce the best cut quality on any material. The operator simply selects the material type and thickness, and the Vision control automatically selects and mixes the optimal start, cut and shield gas combination. Process parameters for most plasma cutting and marking applications are preloaded in the Vision T5 CNC, and custom parameter files can be easily created as needed. The ease and simplicity of part setup is complemented by use of Columbus® CAD/CAM programming and nesting software, designed specifically for plasma, oxy-fuel, laser, and waterjet cutting. This advanced software handles simple to highly complex cuts, multi-process cuts, labeling, and nesting jobs quickly and easily.