EASTEC 2015 (First Tour)

New England’s premier manufacturing exposition returns on May 12-14, 2015 to the Eastern States Exposition in West Springfield, MA. Take a look at some of the equipment that will be exhibited that can help solve your most pressing problems, improve your productivity and increase your profits.

Posted: May 1, 2015

EASTEC is the place that manufacturing ideas, processes and products – highlighted through exhibits, education and networking events – make an impact. With more than 500 exhibitors, complimentary conference sessions, industry keynotes and much more, this event is dedicated to keeping manufacturers in the Northeast competitive. Here are some reviews of selected machinery, tooling, systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

HIGH PRECISION TOOLING SYSTEMS

In Booth 5248, BIG Kaiser Precision Tooling Inc. (Hoffman Estates, IL) will display one of its most comprehensive product line-ups, highlighting several new products that include a new digital boring head series, new tool holding solutions, high-performance drills, workholding for 5-axis and automation, and advanced tool presetting. “Other than in our own showroom, there will not be a more complete display of our products anywhere this year,” said Tim Stapula, the marketing manager of BIG Kaiser. “That, and several new products from across all five of our major lines, make this show one of the best opportunities to explore our industry-leading products.”

KAISER’s entire digital head lineup will be on display, including the new Series 112 EWD 2-32 made for small machines with tight work envelopes. This is KAISER’s smallest digital precision boring head with a concentric insert holder. Features include power management for optimized battery life, inch or millimeter display, IP 69K seal rating, minimized imbalance with tool carrier in center position and optimized bore depth by a through-hole tool carrier. Another focus will be light-weight aluminum solutions for rough boring and large diameter boring.

BIG Daishowa’s two latest product innovations will be on hand as well, revolutions in anti-vibration and anti-pullout technology. The Smart Damper virtually eliminates vibration in deep-hole finish boring and extended-reach face milling. A unique mechanism functions as both counter and friction dampers, resulting in better surface finishes, faster metal removal rates and higher accuracy. Also on display will be the Mega Perfect Grip, a no-slip, anti-pullout milling chuck that combines the cutting performance of heavy-duty milling chucks with security against pullout of solid side lock tool holders.

Also on display will be a trifecta of presetting options. The Speroni products featured will be the benchtop MAGIS and floor-standing FUTURA. The bench-top MAGIS is considered Speroni’s entry-level model – yet it is highly sophisticated and more than capable of handling most shops. The FUTURA is a larger, floor-standing advanced model, easily configured as a full CNC or CNC shrink fit model for complete operator independent measurements. Another presetter system on hand will be the newly redesigned DIASET, an entry-level option now available with some new amenities in high demand in many modern shops like a camera and 8 in LCD touch screen.

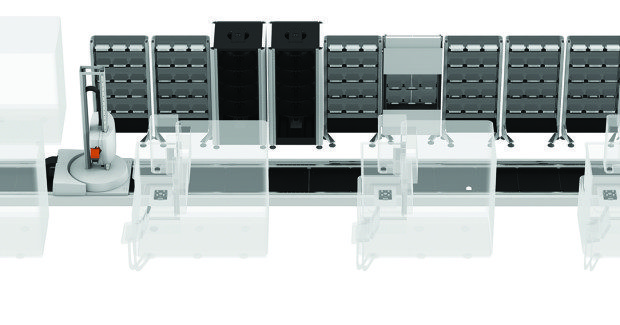

Workholding will be covered too, with Unilock presenting its newest 5-axis automation, the ESA 120/70 chucks. Table integration allows robots to pick and place fixture workpieces into the machine. The system checks for workpiece presence, proper orientation and clamping, and then communicates back to the controller when the workpiece is in place. The best part? This new chuck uses the standard Unilock clamping knobs!

From Sphinx, the bread-and-butter micro tools will be on full display, including a new <80xd micro drill designed to replace plunge EDM operations to create starter holes. Another new deep-hole drill is the Phoenix TC2, up to 30xd, which features a special four-margin geometry, advanced coatings, polished flutes and standard through-coolant capability, and excels in long chipping materials such as stainless steel.

BIG Kaiser Precision Tooling is a leader in high precision tooling systems and solutions focused on extreme accuracy and repeatability, with a mission to support North American manufacturers with products that are designed and manufactured to a superior standard. Guaranteed.

BIG Kaiser Precision Tooling Inc., 2600 Huntington Boulevard, Hoffman Estates, IL 60192, 847-228-7660, Fax: 847-228-0881, bigkaiser@bigkaiser.com, www.bigkaiser.com.

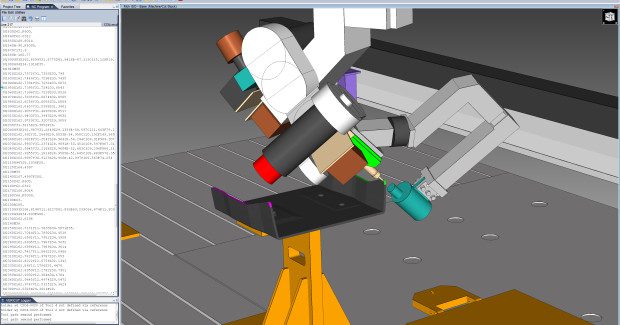

INTEGRATED CNC MACHINE SIMULATION SOFTWARE

In Booth 5344, the latest version of VERICUT® CNC machine simulation, verification and optimization software, V7.3, will be featured by CGTech (Irvine, CA). VERICUT simulates all types of CNC machining and, though it operates independently, can also be integrated with leading CAM systems. A common feature of all recent releases of the software has been the focus on full integration with the CAD/CAM and machine tool industry. As a result, VERICUT is now at the heart of the CNC manufacturing process.

https://youtu.be/nqUR-0hS2EQ

Machine simulation with VERICUT detects collisions and near-misses between all machine tool components such as axis slides, heads, turrets, rotary tables, spindles, tool changers, fixtures, workpieces, cutting tools, and other user-defined objects. Machine movements can even be simulated while stepping or playing backwards in VERlCUT’s Review Mode. With VERICUT Reviewer, shop floor personnel, suppliers, customers, and other production engineers can view animations of the CNC machining process. It is a stand-alone viewer that does not use a license that can play forward and backward while removing and replacing material. The Reviewer files can also be played on an iPad.

CGTech, 9000 Research Drive, Irvine, CA 92618-4214, 949-753-1050, Fax: 949-753-1053, info@cgtech.com, cgtech.com.

EXTRA HIGH CHUCK JAWS

In Booth 5385, DMI Series H extra high chuck jaws from Dillon Manufacturing, Inc. (Springfield, OH) provide extended jaws lengths with heights available to 10 in tall. The longer lengths can provide greater workpiece stability, plus multiple uses of the blank before it is consumed. The extra length also allows the machinist to avoid additional time and costs associated with the welding and bracing needed to lengthen a standard height top jaw. Manufactured from 1018 steel, 4140 steel, or 6061 aluminum, these extra high jaws are available in all standard chuck mounting styles. DMI Series H, extra high jaws are ideal for precision boring, tapping, drilling and finishing.

With production capabilities to produce large runs of special jaws with the same speed and accuracy as small runs, Dillon is uniquely qualified to handle any jaw manufacturing request. They manufacture a complete line of standard and custom chuck jaws, chucks, vises jaws, soft jaws, hard jaws, collet pad jaw systems, chuck lubrication and more. Their applications department routinely works with customers to modify jaws from an extensive catalog of existing designs, or manufacture custom jaws from supplied customer specs/drawings.

The company uses optical checking to check for more than just simple dimensions. Length and width measurements, for example, can be quickly obtained from two separate measurements by using a micrometer. These superficial measurements, however, might not reveal burrs, scratches, indentations or undesirable machined characteristics of a part. Such imperfections are detected on the DMI comparator. ISO registration insures a solid quality management system that is capable of producing consistent, high quality jaws at competitive prices.

Dillon Manufacturing, Inc., 2115 Progress Drive, Springfield, OH 45505, 800-428-1133, sales4@dillonmfg.com, www.dillonmfg.com.

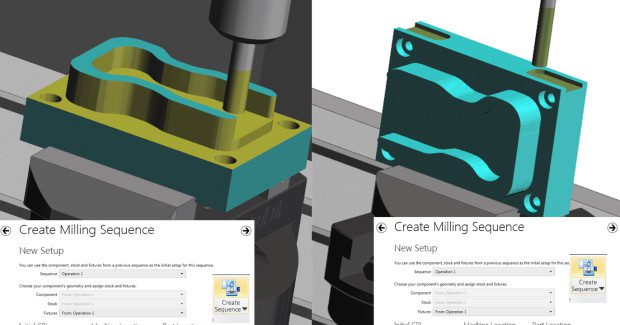

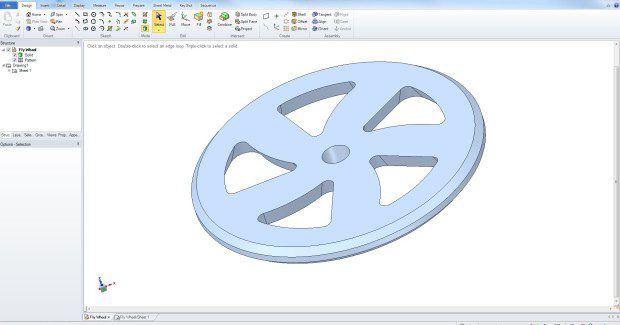

ACCELERATED TOOLPATH GENERATION

Prized for its ability to accurately program any CNC machine tool, Edgecam CAD/CAM software by Vero Software Ltd. (Cheltenham, England) will be featured in Booth 2862, where demonstrations of its efficiency and quality-boosting features will be presented. Among its latest upgrades is Edgecam Workflow, the market leading software application specifically designed for manufacturers to reduce costs, improve quality and achieve shorter lead times. Workflow understands the component topology and understands the required manufacturing environment, therefore accelerating toolpath generation. Workflow will have a significant impact on shortening programming time and, because it is so simple to operate, the learning curve for new users is considerably reduced. With unparalleled ease of use and intelligent toolpath generation, Edgecam is the only CAD/CAM system you’ll need for 3D milling, mill-turn machining, and multi-axis machining.

Vero Software designs, develops, and supplies CAD/CAM/CAE software that radically enhances the efficiency of design and manufacturing processes, providing their customers with exceptional value through high productivity gains and significantly reducing time to market. The company’s world-renowned brands include Alphacam, Cabinet Vision, Edgecam, Machining STRATEGIST, PEPS, Radan, SMIRT, SURFCAM, WorkNC and VISI, along with the production control MRP system Javelin. Despite the diversity of application, these solutions have one thing in common: they all address the rising challenges of achieving manufacturing efficiencies and bring huge value to the operations in which they are deployed.