EASTEC 2015 (First Tour)

New England’s premier manufacturing exposition returns on May 12-14, 2015 to the Eastern States Exposition in West Springfield, MA. Take a look at some of the equipment that will be exhibited that can help solve your most pressing problems, improve your productivity and increase your profits.

Posted: May 1, 2015

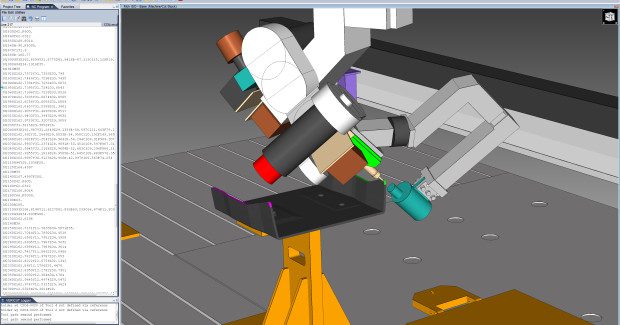

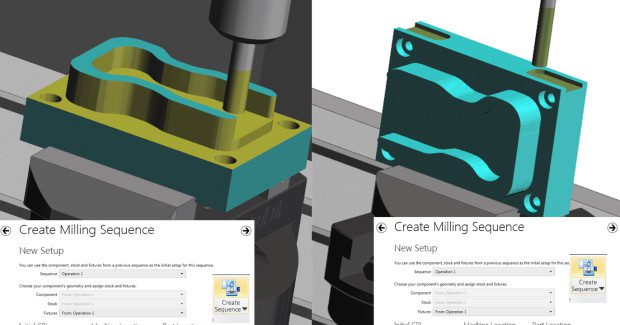

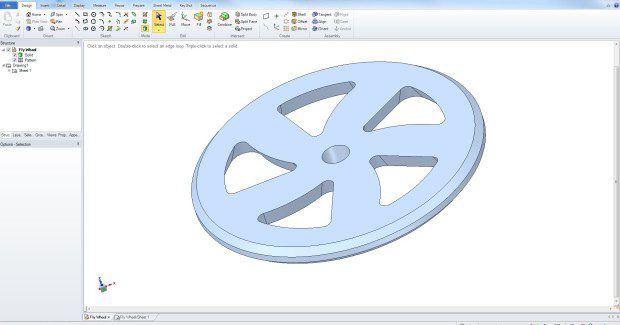

Vero sells and supports their range of products through direct offices in the UK, Italy, France, Germany, Netherlands, the U.S., Brazil, India, Japan, Korea and China, and through a comprehensive global reseller network across more than 45 countries. They are part of Hexagon, a leading global provider of design, measurement and visualization technologies that enable customers to design, measure and position objects, and process and present data.

Vero Software, 25 North Lake Street, Suite 220, Forest Lake, MN 55025, 800-280-6932 x3054, Fax: 651-982-6055, stacey.wiebe@verosoftware.com, www.verosoftware.com.

INNOVATIVE TOOLHOLDING AND GEAR BOXES

In Booth 5459, Exsys Tool, Inc. (San Antonio, FL) offers a wide range of innovative manufacturing technologies, including high-precision toolholding and gear box solutions. The company will showcase the Eppinger brand Compacto™ C3, C4, C5 and C6 base holder system, a full range of gear boxes, and the Preci-Flex® modular quick-change tooling system.

Representing advanced modular quick-change tooling technology, the Compacto C3, C4, C5 and C6 base holder enhances the efficiency and productivity of CNC turning machines. When compared with traditional base holder designs, the compact size of Compacto provides more space for machining in tight workspaces, as well as offers improved torque transmission and rigidity for increased tool accuracy. The holder’s polygon shape connection (PSC), which is the shortest PSC interface in the industry, further adds to its high precision and stability. A special built-in release mechanism on the outer diameter of the base holder’s spindle provides optimum operator accessibility. Operators can easily lock and unlock adapters with a small Allen key for fast and virtually effortless tool changes. Plus, the automatic ejection feature of the adapters further increases the speed and efficiency of tool exchanges.

Available for bolt-on and VDI-style turrets, the Compacto connection base holder accommodates fixed and rotary tools, including the Preci-Flex system, and accepts all standard PSC adapters. In fact, adapters used in milling applications will now work in turning operations, due to the versatility of the Compacto. Show attendees will also see Eppinger’s new line of gear boxes and high precision gear technology. These compact, high-transmission gear boxes are suited for a wide range of applications, including machinery, automation and robotics. Eppinger engineered these products to meet strict demands for stiffness, performance and efficiency, and provide smooth, reliable operation. On display will be:

- Bevel gear boxes – a series of compact gear boxes offering high torque at maximum efficiency for all gear applications requiring a high degree of reliability and variability;

- Hypoid gear boxes – suitable for specific and highly dynamic applications with a specially developed mono-bloc housing for extreme stability and maximum precision and efficiency;

- Planetary gear boxes – the modular design and combination of hardened and ground gears with high precision gear box components guarantees efficient performance, smooth running and high uptime;

- Cycloidal gear boxes – highly compact and rigid cycloidal precision gear boxes well suited for drive technology, especially in tool machinery, automation and robotics;

- Customized gear boxes – specially designed to meet customers’ requirements; and

- High precision gear technology – spiral, hypoid and Zerol gears manufactured with Gleason gear technology.

Exsys will also showcase the Preci-Flex modular quick-change tooling system that features a selection of adapters engineered to hold different cutting tool and shank designs. The adapters’ common connecting feature locks into a standard base unit on the machine turret, enabling tool/adapter assemblies to be preset offline then quickly switch in and out of the base unit. Tool positions repeat within ±3 μm, eliminating the need to re-center, touch off, or make test cuts. The Preci-Flex conical and flat-face planar interface duplicates the taper of the standard ER collet. This enables ER collets, albeit at lesser repeatability, to be used along with Preci-Flex adapters to mount collets, endmill holders, expanding collet chucks and shrink-fit tooling on a single-base holder. Operated at the front face of the turret, the connector provides two tons of clamping force, and its compact design maximizes torque transmission and rigidity, increasing accuracy and productivity.

Founded in 1987, Exsys Tool is the exclusive importer of German-made Eppinger solutions, including high-precision live and fixed toolholders for CNC turning centers, modular adapter systems for quick lathe tooling changeovers and gear box solutions for a wide range of applications. They have support offices in California, Canada and Mexico that support manufacturers throughout North America.

Exsys Tool, Inc., 11654 Corporate Lake Boulevard, San Antonio, FL 33576, 352-588-4345, Fax: 352-588-4821, info@exsys-tool.com, www.exsys-tool.com.

NEXT GENERATION WATERJET SOFTWARE

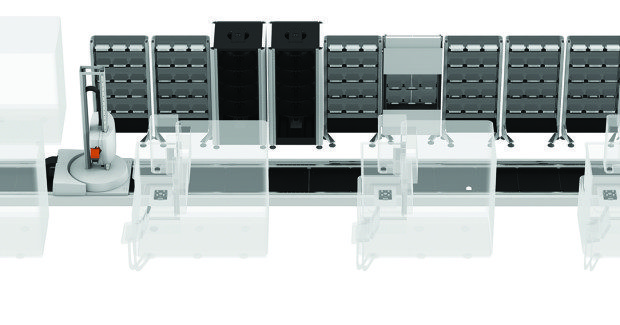

Flow International Corporation (Kent, WA), a leading developer and manufacturer of industrial waterjet machines for cutting and cleaning applications, will run live demonstrations of their Mach 3 waterjet in Booth 1712 and feature the newest advancements in intelligent waterjet software with FlowXpert™ 2015 alongside the Mach 3 system. The FlowXpert Software Suite is a robust 3D CAD/CAM platform that expands on the 2D FlowMaster® intelligent Software Suite. The platform includes Design powered by SpaceClaim, an integrated 3D modeling tool with Flow Sequencer. With this release, the integrated CAD/CAM capabilities give users a seamless pathing experience. The integration with Flow Sequencer adds flexibility to users and is designed specifically for waterjet cutting, resulting in faster waterjet programming.

With thousands of installations worldwide, the Mach 3 is the world’s most popular waterjet. The system design combines motion control, high-pressure components and pump into one compact machine. During the show the Mach 3b will combine the HyperJet® pump, rated at 94,000 psi, and Dynamic Waterjet® XD high-precision flat stock and 3D cutting technology that will demonstrate the newest in waterjet height sensing technology, the DynaBeam™ Laser Height Sensing System. DynaBeam is the only non-contact material height sensing solution available in the industry and can be used in combination with Dynamic Waterjet XD for 2D and 3D bevel cutting. Application specialists will be on hand to answer questions and demonstrate how Flow’s waterjet technology provides fast and highly accurate cutting across all of our systems.

Flow International Corporation, 23500 64th Avenue South, Kent, WA 98032, Fax: 253-813-9377, info@flowcorp.com, www.FlowWaterjet.com.

AUTOMATED MACHINING SYSTEMS FOR AEROSPACE WORK

GF Machining Solutions (Lincolnshire, IL) will display high-performance automation solutions and a wire electrical discharge machine (EDM) designed specifically for aerospace work in Booth 1236. Products highlighted will include the new Mikron HEM 500U high-efficiency milling machine, CUT 200 Sp wire EDM, System 3R Transformer automation, and the FORM 20iRTC sinker EDM. Visitors to the booth will also see a variety of EDM consumable products including high-performance EDM wires.

The Mikron HEM 500U high-efficiency milling machine with a 10 position pallet changer (PCH) provides high-performance, high-value 5-axis capabilities to manufacturers focused on efficient, accurate and reliable parts production. Ideal for cutting parts from aluminum alloys and steel, the HEM 500U features a highly dynamic 12,000 rpm ISO-B40 spindle and 30 tool magazine that provides a 2 second chip-to-chip time for high-speed continuous milling operations and increased spindle uptime. Additionally, a 20,000 rpm spindle and 60 tool changer are available. A trunnion table measuring 19.7 in diameter and accommodating workpiece weights up to 440 lb tilts -65/+110 deg in the B-axis and rotates 360 deg in C for 3 + 2 machining as well as 5-side positioning. Axis travels in X, Y and Z measure 19.7 in, 17.7 in and 15.7 in, respectively, while a distance of 5.9 in between the machine spindle nose and rotary table surface allows for ample maneuverability around workpieces.

The HEM 500U relies on a new Heidenhain iTNC 530 control for quick and reliable machining. This versatile, workshop-oriented control for 5 (3 + 2)-axis machining features an integrated digital drive control with integrated inverter, enabling it to produce a highly accurate workpiece contour while machining at high velocity. The HEM 500U also comes equipped with Smart machining modules that provide advanced levels of monitoring critical to the production of aerospace and defense parts.