Innovative Pipe Purging System for Welders

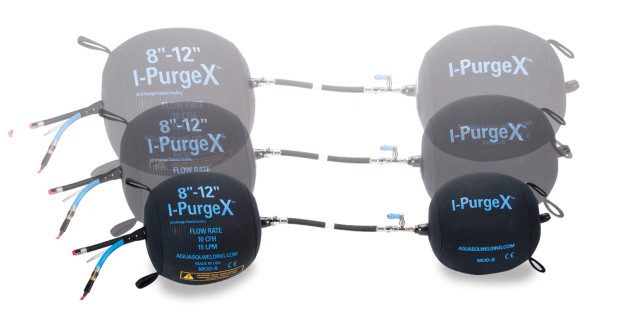

Components of the versatile and adaptable I-Purge and I-Purge X Modular Inflatable Bladder Systems combine to offer welders more customized solutions for pipe purging than ever before.

Posted: May 11, 2015

Aquasol Corporation (North Tonawanda, NY) offers their patent-pending I-Purge® and I-Purge® X Modular Inflatable Bladder Systems, the most innovative purging device to date. By far the most versatile and adaptable inflatable system available on today’s market, I-Purge and I-Purge X Modular System components combine to offer the welding industry more customized solutions for pipe purging than ever before.

Equipped with unique Quick-Connect fittings, components easily snap on and off in seconds. A variety of standard harness lengths allow the user to customize length based on individual project needs, enabling placement of the bladders outside the heat-affected zone (HAZ). These flexible, high heat harnesses allow for navigation through elbows and T-joints, and have a central point marked with a luminescent indicator for easy alignment with the center of the root gap.

The I-Purge Modular System is comprised of two spark-resistant, inflatable bladders connected by a high-heat resistant bridge harness. Unlike other purge bladders with permanent fittings, this ground-breaking design allows for the creation of a by simply connecting two bladders of different, yet similar, diameters.

A tri-flow hose maximizes efficiency by enabling bladder inflation and quick flooding of the purge area with noble gas. An innovative tubing system provides separate connections for inflation of bladders along with introduction of inert gas to the weld zone to expedite the purging process. The inflated bladders create an airtight seal against the pipe walls and a superior barrier. Another connection enables monitoring of exhaust gases ensuring an oxygen-free environment. The patent-pending diffuser evenly distributes gas throughout the purge area, greatly reducing turbulence. Once the weld is complete the bladders can be deflated, extracted, cleaned, and stored in the convenient carrying bag provided with every system.

Yet another feature showcasing the system’s flexibility is the ability to modify the I-Purge with the Isolator™ Adaptor Kit into a one-sided plug. An isolator can be used to close off the end of a pipe for servicing, cleaning, inspection, or sealing.

The I-Purge Modular System can be used multiple times thanks to its durable construction and high quality components. Aquasol has again simplified the purging process with another unique, patent-pending product, providing the industry with most versatile option to date. Bladders are available in sizes ranging from 2 in to 48 in and may be purchased either individually or as a complete system, a distinct advantage should a bladder need to be replaced.

info@aquasolcorporation.com, www.aquasolwelding.com