Safeguarding the Shop

A review of some of the latest machine safeguarding devices and related shop safety systems designed for protection of both employees and equipment in the workplace.

Posted: May 1, 2015

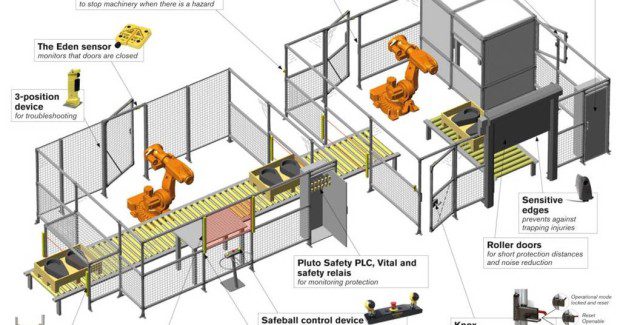

ADVANCED MACHINE SAFETY SYSTEMS

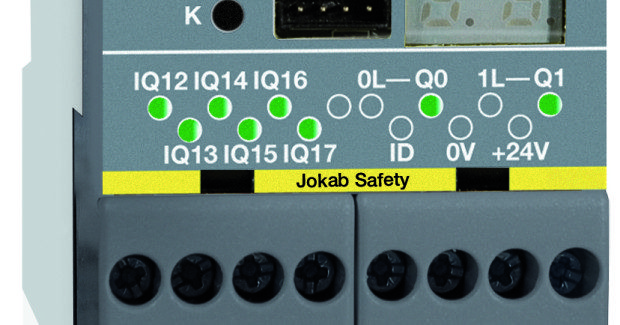

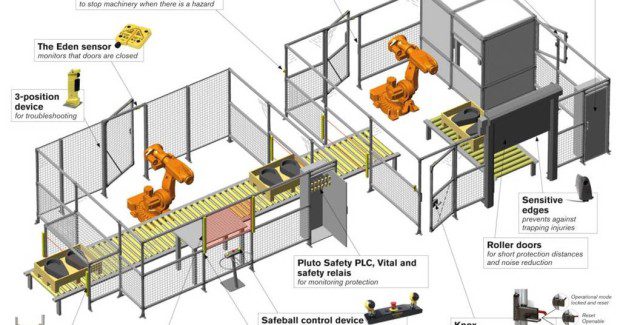

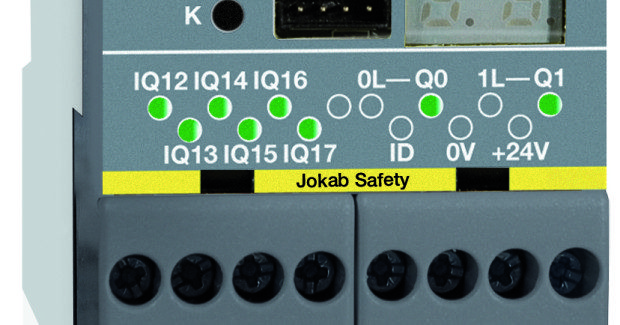

For nearly three decades, ABB Jokab Safety (Westland, MI) has offered complete protection solutions, from individual safety components to safety PLC controlled custom processes to complete machine safety systems that provide enhanced safety for personnel and more uninterrupted production time that means a better bottom line. These reliable and cost effective machine safety solutions can boost productivity and earnings for manufacturers by helping to protect machine operators, staff and equipment while meeting standards and regulations.

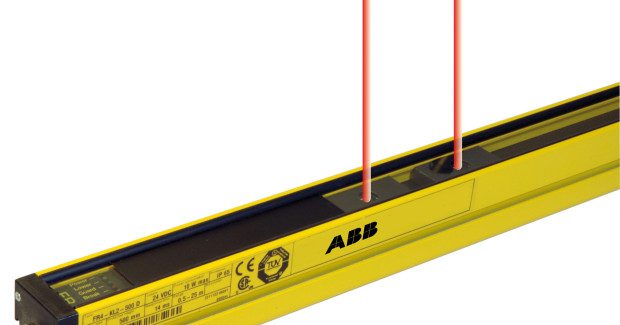

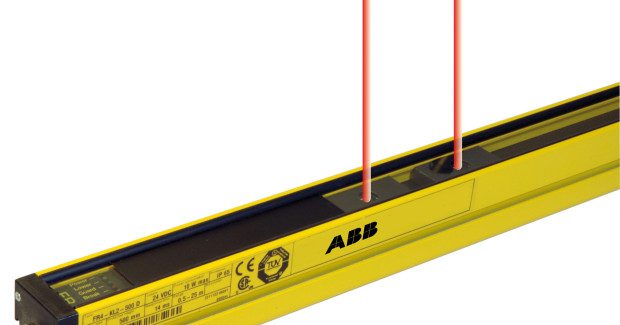

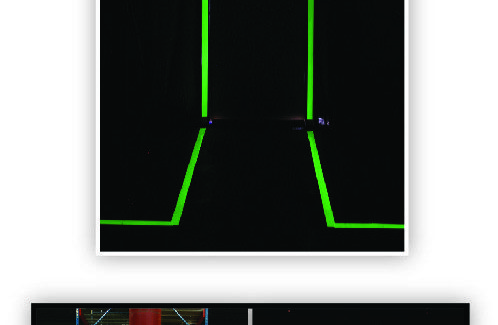

For example, Focus II Light Curtains and Light Grids are an updated version of the Focus product line designed to offer the complete range of features in one low cost package. A single Focus II Light Curtain or Light Grid model can be used for all applications, eliminating the need to order or stock a multiple versions for varying machine safety requirements. Light curtains and grids protect personnel from potentially hazardous machinery, robots or automated systems by creating a protection field with infrared beams, which, if interrupted, trigger a safety mechanism that immediately stops the machinery. Light curtains are typically used for inner area protection closer to machinery, with multiple beams placed between 14 mm and 30 mm apart. Light grids are for protecting areas further away from machinery, consisting of two to four beams placed between 200 mm and 500 mm apart.

Both Focus II Light Curtains and Light Grids meet the highest level of safety and have received all necessary national and international approvals. Both the curtains and the grids consist of two optical units, a transmitter and a receiver, which are continuously scanned, quickly detecting any objects that break the optical barrier. If any light beam is interrupted, the dangerous machine movement is stopped by the outputs from the light curtain. The reaction time for Focus II varies from 14 ms to 45 ms, depending on the number of beams in the light curtain or grid. Five LEDs in the receiver and the two in the transmitter show the status of the light curtain. Additional features include:

- Quick connects and custom adjustable brackets for unsurpassed ease of installation.

- Flexible, built-in muting capabilities with inputs for partial or complete muting.

- A muting override function which makes it possible to bypass the light curtain, i.e. activate the outputs if a machine start is necessary even if one or more light beams are interrupted.

- Floating blanking which makes it possible to disconnect a defined number of beams from the safety field, enabling an object to cross the optical barrier without the safety function being triggered.

With the introduction of the Focus II Light Curtains and Light Grids, manufacturing has been moved to the U.S. (in Westland), enabling Jokab to lower list prices and deliver product from stock in five days. The light curtains light grids are ideal for a variety of applications, including:

- Mechanical and hydraulic power presses

- Molding presses

- Stamping, riveting and eyelet operations

- Automated machinery and manufacturing cells

- Robotic cells

- Conveyors

- Material handling equipment

- Welding equipment

- Machining centers

Time, space and a high safety level are essential factors for many machines today. This is why the new small and robust Smile E-Stop was developed. Its size and centered mounting holes make it easy to install, especially on aluminum extrusions like those used in Quick-Guard Fencing Systems. The Smile E-Stop unit has one or two M12 connectors. Outputs provided are either two dual ‘breaking’ contacts or a Tina interface, which makes it possible to connect several E-Stop devices in a dynamic safety circuit according to Category 4. LED indication of E-Stop status is also provided: green for OK, red for STOP and blinking if the circuit has been opened by another series connected sensor.

Eden is a non-contact, non-magnetic sensor that uses dynamic signal transmission to offer Category 4 safety levels through built-in diagnostics and a maximum sensing distance of 15 mm (±2 mm). Up to 30 Edens can be connected together in the same circuit and be dynamically monitored by the Vital Safety Module or Pluto Safety PLC. Eden E manages harsh environments, e.g. high-pressure wash-down and high and low temperatures (tested from +100 deg C to -70 deg C according to IP69K).

ABB Jokab Safety, 6471 Commerce Drive, Westland, MI 48185, 734-467-6338, www.jokabsafetyna.com.

FREE-STANDING SHIELDS

Danray Products LLC (Rockford, IL) offers free-standing shields that can be used in many applications for safeguarding as well as for housekeeping. Ideal for lathes and milling machines, these shields can be applied between machines, on the backside of machines, and along aisles. They can also be used in other applications to protect individuals from flying chips, sparks, coolant, lubricant, and other particles. These assemblies are constructed of 1½ in square extruded aluminum with a 48 in W x 36 in H x ¼ in thick polycarbonate panel and include fasteners and a safety sign. The shield can be adjusted up or down on the posts. Custom sizes are available upon request.

Danray Products LLC, 973 Featherstone Road, Unit 115, Rockford, IL 61107-5908, 815-262-6667, Fax: 815-282-5186, ryan.ebens@danrayproducts.com, www.danrayproducts.com.

LASER SCANNERS MONITOR MACHINE SAFETY

OS32C-4M safety laser scanners from Omron Electronics, LLC (Hoffman Estates, IL) are Type 3 safety laser scanners that provide a 4 m safety range, 15 m warning zones and an impressive 270 deg detection angle that is perfect for safeguarding large robotic cells and body entry detection. They can also be mounted 4 m high to eliminate the possibility of tampering. New pollution tolerance modes ensure safe machine operation, even in the dirtiest and dustiest application environments, resulting in more flexible safety monitoring and configuration that enables improved machine safety and productivity. All models meet global standards for worldwide application; select models are available for same-, 3- or 5-day shipment.

These safety laser scanners can report status and measurement data via EtherNet/IP™ to help keep machines up and running by enabling users to check the operating state and analyze the cause of an emergency stop via LAN, and take quick corrective action, even in large-scale applications with multiple scanners. They are also available with user tools that help speed customer development time and conserve engineering resources. “Easy to use function blocks are ideal for simple PLC controlled status and data updates. A simple and effective method of integrating the status and measurement data to a PLC, these function blocks can be used in the PLC code to automatically configure the PLC to process and display the information. Software examples are available for large process PC controlled applications where large amounts of data are logged to determine product quality, consistency or process variations,” explains Mike Frey, the product marketing manager for safety at Omron.

Additionally, the configuration tool provides a “maintenance access level” that enables users to make only non-safety related programming changes, and employs a “non-safety checksum” for easier re-commissioning when non-safety changes are made. A “zone coordinate import/export” function allows users to modify the shape and size of a monitoring zone by importing coordinates from a text file. All OS32C safety laser scanners provide configurable object resolutions of 30, 40, 50 and 70 mm to accommodate hand and arm detection applications. They feature a compact 104.5 mm profile, light 1.3 kg weight and consume just 5 W power (3.75 W in standby mode). Combined with innovative features that include up to 70 sets of highly flexible and easily configurable detection zones, the OS32C is easy to handle and install, and delivers the versatility needed to solve diverse presence detection and collision avoidance application needs. The status display and eight patented Individual Sector Indicators also enable users to determine at a glance the unit’s operating state and error codes, and assess the direction of an intrusion.

Omron Electronics, LLC, 2895 Greenspoint Parkway, Suite 200, Hoffman Estates, IL 60169, 847-285-7176, Fax: 847-285-8176, omroninfo@omron.com, www.omron247.com.