Visual Thinking for the Shop

Every shop uses some sort of work instruction method, but the majority of the time it is not ideal. Now there is a new way to easily create and share work instructions, standardize best processes, reduce errors, increase efficiency, and most importantly, satisfy customers.

Posted: May 5, 2015

"Do not invest or commit to visual inspection software without test driving. Make sure the software is the right fit your company. From free-trials to one of our pilot programs, we take the time to get to know your facility and operations, and work with you to build work instructions, implement on the shop floor and train everyone who is going to be involved."

Standardized work is the foundation of continuous improvement that instructs an operator how to perform a precise sequence of work within a specified time, using standard inventory with defined tools and machines that are required to operate smoothly. Every shop uses some sort of work instruction method, but the majority of the time it is not ideal . . . not ideal to create, to update, to maintain, or even to use from an operator’s point of view.

To address these problems, Visual Knowledge Share (VKS) is a cloud-based visual instruction software that can be used by job shops, contract manufacturers and metal service centers to easily create and share work instructions, standardize best processes, reduce errors, increase efficiency, and most importantly, satisfy their customers.

This fast, simple and powerful software was initially developed by sheet metal manufacturers who were constantly losing business opportunities to cheaper overseas labor markets. In order to remain competitive, they focused on zero-defect manufacturing that was centered around standardized best processes. To do this, they taught their operators to follow the best processes in a step-by step manner at their work stations, they then began using images and video to capture and share essential quality techniques and productivity control methods. This system created sets of visual instructions that made it incredibly difficult for human errors to occur.

These visual instructions minimized the frequency of human error, enabled this sheet metal fabricator to start saving lots of money, and eventually evolved into a new type of cloud-based visual instruction software for niche applications that never existed until recently.

VKS is not an enterprise resource planning (ERP) platform or a material requirements planning (MRP) system or a manufacturing execution system (MES). Instead, this visual instruction software focuses on the actual work instructions themselves. Data capturing, forms, reporting, key performance indicators and everything else are all additional features. The software simplifies all of that while giving management 100 percent traceability and operator accountability on all jobs that roll through the shop floor.

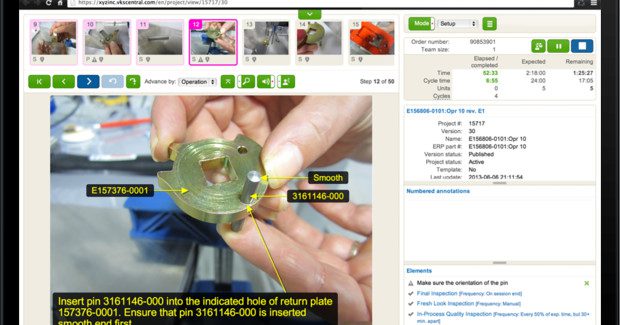

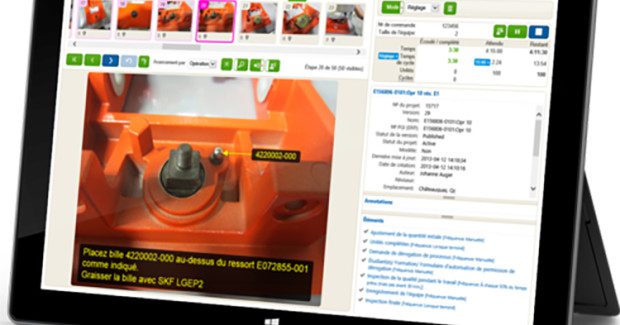

The concept behind visual instruction software is simple. Operators show up to their work station (whether it be in a machining cell, on a fabrication line or at an assembly bench) and log into the application by using any device that can connect to the Internet. The software is a browser-based solution, so as long as the person has Internet access they can use it. Operators log in with a username or password, or by scanning a barcode. After entering the system they manually locate the work instructions for the assigned job by using different built-in search filters, or they can scan a barcode off a traveler document for the operation that is about to be performed.

Upon opening their work instructions, the operator is immediately prompted with a form that asks for the Work Order number, the quantity, and the standard takt time for that job. This data can be entered manually by scanning a barcode off the traveler associated to that operation, or by linking VKS directly to the company ERP system so that the instruction software’s application programming interface can automatically pull that specific information. This data is then displayed to the operator along with his work instructions on the screen.

As the operator follows the work instructions step-by-step they remain aware of how many units are completed vs. the number required to complete the order. They also see how much actual time they have taken vs. the standard time the job is supposed to take. In this way, the visual instruction software monitors their efficiency and productivity without distraction.

At any point throughout a process an operator can be prompted with custom forms, process questionnaires or quality inspection checklists (data input fields) that can be embedded directly into their work instructions. For example, a shop that previously recorded a variety of quality data onto spreadsheets, ranging from critical dimensions to final inspections, can now embed this data into their work instructions and select the frequency at which they appear on the screen as the work is being performed. The visual instruction software captures this data and promotes individual accountability by preventing the operator from proceeding to the next step of the process until they fill out and save their inspection form.

All of this accumulated data is stored within a reporting portal that is used by managers to check who is logged in, what job they are working on, how long they are taking, how many units they have finished, etc. They can fully trace and monitor every job that runs through their shop.

This visual instruction software can be used in any shop environment. While highly manual processes are usually thought to be more suitable for this sort of application, many shops use this software in heavily automated environments. For every machine tool that runs a job, a human somewhere is in charge of making sure that equipment operates properly, including loading, unloading, set up and maintenance. VKS is used in these situations all the time and, with the convenient ability to embed specific quality inspection checks directly into the indirect facets of the operation, the shop can achieve higher degree factors of accountability and traceability.

The return on investment from visual instruction software is generated through massive increases in shop quality, productivity, training effectiveness, and significantly reduced operating expenses that are associated with less waste and non-value added time. However, no shop should invest or commit to visual instruction software without first doing a test drive to evaluate which software is the right fit for their operation.

Any manufacturer that is interested in visual instruction software should first look for suppliers that offer free trials or can be part of a pilot program. They should make sure the software supplier takes the time to get to know their facility and operations and collaborates with them to build work instructions, implement those instructions on the shop floor and train everyone who is going to be involved on how to use them.