Fine Tune That Cutting Process

Take a look through this assortment of new cutting tools and discover how they can reduce your machining costs and improve your precision to whole new levels.

Posted: June 4, 2015

- Variable Helix End Mills – Square – Free Machining

- Plastic Cutting Finishers – Square Upcut High Helix – 3 Flute

- Plastic Cutting Finishers – Square Upcut Slow Helix – 3 Flute

- Undercutting End Mills – 300 deg Reduced Shank

- Undercutting End Mills – 270 deg Reduced Shank

- Chamfer Cutters – Plate Chamfer Cutter

- Thread Milling Cutters – Multi-Form – Long Length of Cut

- Thread Milling Cutters – Thread Relief Cutter

Every tool in the catalog is stocked. Over 60 percent of these tools are typically unavailable anywhere else on the market. These unique product offerings allow customers to purchase specialty tools “off the shelf” with same-day shipping, eliminating long and costly lead time.

Harvey Tool Company, LLC, 428 Newburyport Turnpike, Rowley, MA 01969, 978-948-8555, Fax: 978-948-8558, sales@harveytool.com, www.harveytool.com.

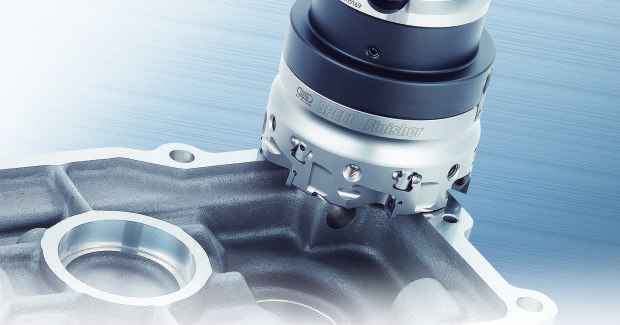

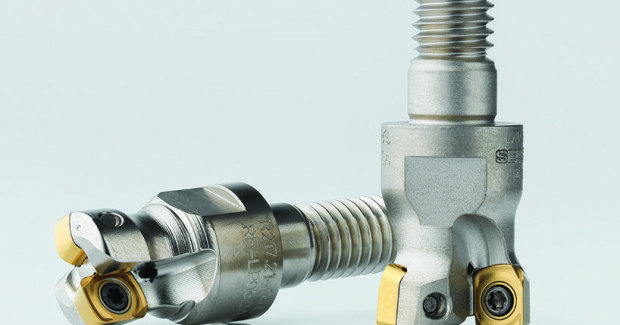

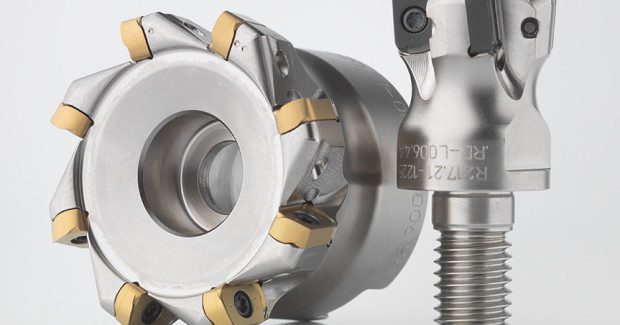

TROUBLE-FREE GROOVE MILLING

The main challenge in groove milling is often chip evacuation. Chip issues can harm production efficiency, lower component quality or cause tool breakage, especially when machining narrow and deep grooves. Dedicated for groove milling and parting off operations, CoroMill QD® from Sandvik Coromant US (Fair Lawn, NJ) takes care of chip issues with optimized geometries and a unique internal coolant solution. The insert geometry deforms chips to a more narrow shape than the groove, and then the chips are flushed out by coolant. This technology, combined with long and predictable tool life, makes CoroMill QD a reliable solution for secure and trouble-free production processes.

A wide range of new adapters complements the new cutters. These adapters enable use of CoroMill QD cutters regardless of whether the preferred machines are small- to medium-sized machining centers, large machining centers or multi-task machines. Silent Tools™ adapters are available for long overhang machining. The internal coolant is based on a four-channel delivery solution from the adapters to the cutter. By implementing this solution on the new adapters for CoroMill QD, coolant delivery into the groove is achieved.

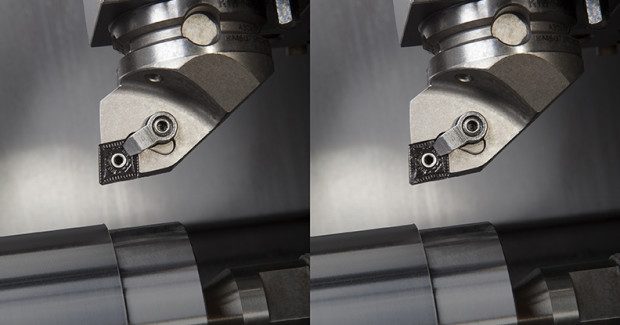

Seal ring grooves are a critical feature on many oil and gas components, requiring close tolerances and high-quality surface finish. Conventional methods for machining seal ring grooves often result in slow production and poor process security. Multiple-operation approach, incorporating both roughing and finishing sequences, is another challenge. The tools used are single point- or plunging cutters that are prone to vibration. Difficult-to-machine materials, such as solid Inconel 718 and cladded Inconel 625, are often used, only adding to the long list of challenges to overcome. SpiroGrooving™ is a machining method from Sandvik Coromant that is used with the CoroBore® XL system to utilize a spirograph tool path to create close-tolerance seal ring grooves in a secure and productive way.

This system is ideal for making seal ring grooves in pre-clad machining of steel and stainless steel. The unique internal coolant feature of CoroBore XL enables machining in advanced materials. Roughing and finishing are carried out in the same operation, thereby significantly reducing machining time and improving productivity. Altogether, this solution ensures high output of quality components and process security when machining seal ring grooves. SpiroGrooving uses a circular spirograph tool movement in a taper that reduces chip thickness, enabling light cutting action and increased feed. Parts of the insert cutting edge have an interrupted cutting behavior, eliminating long chips that can tangle the tool and spindle. With a unique NC-code generator, SpiroGrooving is programmed in just a few easy steps.

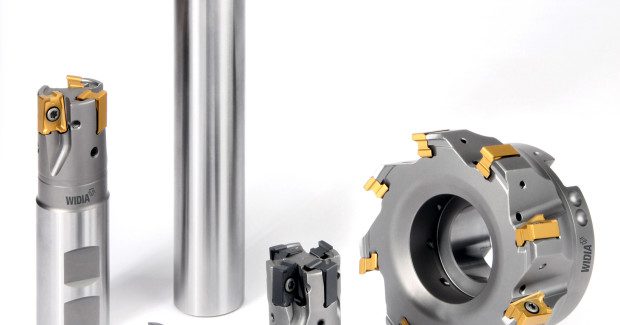

Sandvik Coromant also offers the CoroMill Plura HD, the first choice solid roughing end mill for shoulder milling, full slot milling, and ramping and helical interpolation in steel and stainless steel. It can also be used with cast iron and heat-resistant materials. The tools offer secure and reliable machining in a wide range of cutting parameters.

High process security and long predictable tool life are essential in heavy roughing operations. CoroMill® Plura HD’s optimized flute shape was a result of the valuable insight gained from a Finite Element Analysis. The flute shape assures effective chip evacuation when machining a large depth of cut. The design also prevents re-cutting of chips and sudden tool breakage. By efficiently removing chips, full slot milling up to two times diameter with five-teeth end mills is possible without compromising process security. Internal coolant also promotes maximum chip evacuation and temperature control in stainless steel end mills.

The geometrical features and grades allow for exceptional metal removal rates and tool life. Two new grades have been developed: one for all-round conditions, preferably in dry machining, and one to deal with tough conditions and large engagements in wet machining. The tough face geometry was developed to cope with demanding ramping operations. Other features include differential pitch and cylindrical land to help minimize vibration and to provide predictable performance for reliable roughing.

Sandvik Coromant US, 1702 Nevins Road, Fair Lawn, NJ 07410-0428, 201-794-5000, Fax: 1-201-794-5157, us.coromant@sandvik.com, www.sandvik.coromant.com.

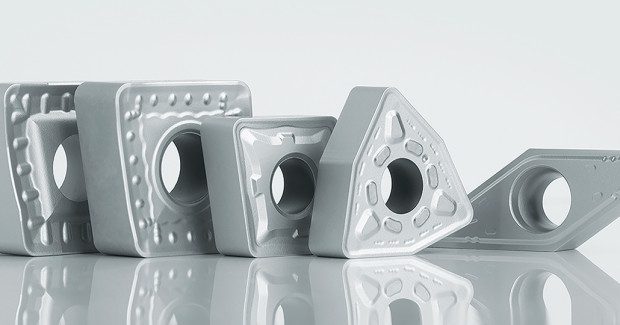

TURNING TOUGH MATERIALS

With the unveiling of its next-generation Duratomic Technology, Seco Tools, LLC (Troy, MI) introduces three new turning insert grades that achieve the elusive balance of toughness and hardness when machining steel alloys and other workpiece materials such as cast irons and stainless steels. The TP2501, TP1501 and TP0501 represent an evolution and expansion of the Duratomic technology introduced in 2007 that was the industry’s first textured, a-based Al2O3 coating. The Duratomic CVD aluminium-oxide coating process manipulates coating components at an atomic level to achieve improved mechanical and thermal properties and enhance performance.

https://youtu.be/ci2ad_fk9dY

The TP2501, TP1501 and TP0501 combine the benefits of advanced aluminum-oxide coatings with specially developed compositions of the tools’ bulk substrates and cobalt-enriched zones. Modifications of those elements make the new grades both tougher and more wear resistant than their predecessors, across the board. The latest Duratomic technology used in TP2501, TP1501 and TP0501 improves productivity by at least 20 percent in average turning applications as compared with the original TP2500, TP1500 and TP0500 grades. These new grades handle a wider range of speeds, allowing manufacturers to apply them to applications requiring higher or lower speeds while maintaining comparable tool life.

In addition to achieving the toughness and hardness balance, the new inserts incorporate Edge Intelligence, an innovative used-edge detection technology. The insert surfaces feature an approximately 0.1µm-thick chrome-colored coating. Black aluminum oxide showing through the chrome-colored coating clearly identifies a used insert edge and allows operators on busy shop floors to easily spot them. Also key to Edge Intelligence is that its high-contrast used-edge marks do not impact tool performance or machining-related parameters such as cutting data. As a result, manufacturers can process more parts per edge, limit production interruptions and reduce waste.

TP2501, TP1501 and TP0501 are available in a broad range of insert sizes and geometries to accommodate everything from roughing to finishing operations. The three grades’ application areas overlap, resulting in a seamless progression, without gaps, from inserts engineered to reliably handle a wide range of general applications at moderate cutting speeds through tools that permit process optimization with higher parameters.

TP2501 is a versatile grade with highly secure edge toughness behavior that brings dependable productivity and reliable part production to general steel turning applications. It is the preferred grade for operations that involve a variety of workpiece material requirements and unpredictable working conditions. TP1501 is a general grade with well-balanced properties that make it ideal for applications requiring high wear resistance in low-alloy steel workpieces. Furthermore, the grade offers the potential for higher cutting speeds, while the high reliability and accuracy ensures consistent part quality.

TP0501 is a general grade best suited for stable machining conditions and situations requiring high output. Of the new TP grades, it provides the highest possible wear resistance and/or cutting speeds in high-alloy and abrasive steel turning applications. Furthermore, the extreme heat resistance of the TP0501 makes it possible for users to achieve high metal removal rates without the need for coolant.

Seco Tool’s latest Jabro JPD and JC end mills offer fast, efficient cutting to part-processing applications involving carbon and glass-fiber composites and carbon and glass-fiber reinforced plastics. The end mills come in four new geometries. The JDP group that consists of the new 880 square end mill, 850 ball nose end mill, and 840 compression-type end mill features brazed polycrystalline diamond (PCD) plates. Main PCD-plated bodies include through-coolant channels for chip and dust evacuation. The JDP880 and JDP840 end mills are available in diameters that range from 6 mm to 16 mm, while the JDP850 covers diameters from 4mm to 16 mm. Two PCD plate lengths – normal and long – are also available for the JDP880.

The JC group of solid-carbide end mills includes a new 875 solid-carbide router for superior surface finishes via a special edge treatment that prevents wear. An added diamond coating allows it to withstand the highly abrasive properties of composite materials. A special chip-splitting design offers clean cutting actions. Diameter ranges for the JC875 are from 3 mm to 12 mm, with 0.250 in to 0.500 in Imperial sizes also available. The four geometries incorporate advanced designs to allow composite workpiece materials to remain undamaged during the machining process.