Hybrid Wire for EDM Machining

The hybrid wire features a baked-on external zinc layer for maximum speed (average 30 percent higher than conventional brass wire), superior accuracy, surface finish and clean cutting.

Posted: June 20, 2015

MC Machinery Systems, Inc. (Wood Dale, IL), a wholly owned subsidiary of Mitsubishi Corp., announces the release of its ZT Hybrid Wire for EDM machining. The hybrid wire features a baked-on external zinc layer for maximum speed (average 30 percent higher than conventional brass wire), superior accuracy, surface finish and clean cutting.

“Users will notice a difference the very first time they use ZT Hybrid Wire,” said Scott Watton, the product manager of the Consumable Products Group at MC Machinery Systems. “Water is everything in EDM and this wire is built to take full advantage of its properties to do everything better . . . cut, clean, cool and so on.”

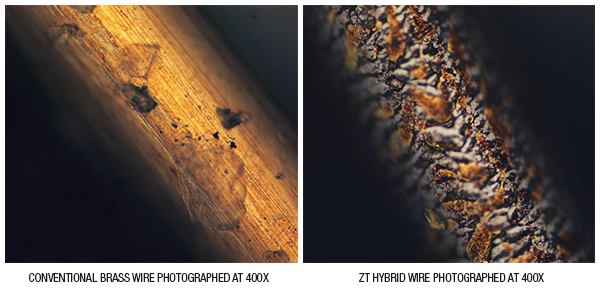

The baked-on zinc coating forms microscopic, precision pockets on the wire’s surface that allow more water to integrate in to the cutting process. The extra water allows for maximum spark energy for faster, more accurate cutting as well as finer finishes. The added texture also gets water closer to the brass core allowing for more efficient off-time cooling, minimizing the risk of electrode breakage.

The unique baking process adheres the outer zinc layer to the wire’s brass base better than conventional coating. This strong bond makes ZT Hybrid Wire more resistant to flaking, resulting in a cleaner cutting process that can reduce machine tool maintenance and extend its life.

The ZT Hybrid Wire is available in both hard and soft versions, P2 through P15 and K125 through K250 size spools. It’s also backed by the Consumable Products Group’s no hassle replacement guarantee.

MC Machinery Systems, Inc., 1500 Michael Drive, Wood Dale, IL 60191, 630-616-5920, www.mitsubishi-world.com.