Vertical Machining Centers

Take a look at the advantages of affordable flexibility now being offered in the newest vertical machining centers.

Posted: June 4, 2015

Various magazines with up to 200 tool positions can be selected. The wide choice of tools is also beneficial to retooling times and the overall equipment effectiveness (OEE) can be increased by up to 30 percent as a result. Only the clamping method must be tailored to the workpiece; the tool buffer is fitted with an adequate number of tools at all times. The operating condition of each tool is ensured by a laser measuring bridge outside the machining area that checks the wear, the diameter of the tools and the tip distance to base of turning tools to ensure that the machine produces a perfect production result every time. An interchangeable radio probe can be used for quality management purposes and to check the workpiece quality.

The VMC MT series is not just convincing in terms of its machining quality, but also in the excellent ergonomics. The machining area and all maintenance components are easy to access, demonstrating how the design of the machine centers on small production runs with a wide range of workpieces and on prototype production. Machine operators can take advantage of the tailored working conditions to make the machine so productive.

With the VMC MT series, EMAG offers a new machine system for chucked parts suited to the production even of the most complex workpieces in many different manufacturing scenarios thanks to its flexibility. Whether components for the aircraft industry, trucks, construction or agricultural machinery, the universal nature of VMC MT Series makes it relevant for almost every sector. The machines are an all-around solution for chucked parts, above all for frequently changing component families that take advantage of their highly flexible adaptability.

EMAG LLC, 38800 Grand River Avenue, Farmington Hills, MI 48335, 248-442-6719, Fax: 248-447-7784, kkilgore@emag.com, www.emag.com.

LARGE WORK ENVELOPE INSIDE COMPACT DESIGN

Kitamura Machinery of USA, Inc. (Wheeling, IL) introduces the Mycenter-3XD, their latest compact, high capacity vertical machining center that is affordable, reliable and durable, and designed with space saving flexibility and ease of use for the operator in mind. Truly compact, the Mycenter-3XD harnesses an ample table size of 500 mm x 800 mm (19.7 in x 33.9 in) along with 760 mm x 510 mm x 510 mm (30 in x 20.1 in x 20.1 in) X, Y, Z travels, making it ideal for small to medium sized workpieces. High speed rapid feed rates of 48 m/min (1,889 ipm) X and Y, 42 m/min (1,654 ipm) Z on heavy duty cross roller linear guide ways are combined with stiff cast construction.

Meehanite cast C-frame construction ensures unparalleled rigidity durability and stability. All contact surfaces are hand scraped for precise alignment, fit and performance ensuring high quality and attention to detail in the manufacturing process. Heavy duty cross roller linear guide ways offer the strength necessary to carry heavier loads and power through heavier cuts. The dual contact 12,000 rpm, 30 hp AC spindle system is standard – the ultimate in power for a machine of this size, far exceeding industry standards. The high performance, highly efficient NRG belt drive means highly transmissible torque and power from the motor to the spindle with less vibration and noise that guarantees smooth operation, reliability and stiffness to keep the machine up and running. The 12,000 rpm spindle speed affords the flexibility to efficiently machine a wide variety of materials with maximum machining rigidity and extended cutting tool life. A 15,000 rpm spindle is an available option.

The ATC assures smooth and effortless tool changes. A generous 24-tool capacity reduces idle time and boosts productivity and machining profits. For additional requirements, 30 tools is offered as an available option. High efficiency chip evacuation is ensured with standard base wash system, internal chip augers and a scraper type chip conveyor keeping the large workspace free of chips and contaminants. The standard scraper type conveyor can be installed on either the right or left-hand side of the machine, depending on space requirements.

The Mycenter-3XD is equipped with a state-of-the-art Arumatik-Jr. CNC controller that is packed with high speed machining functions second to none. It offers up to 16X faster processing speeds when compared to conventional controls. Superior standard features include 675 block look-ahead, 1,280 meters memory, USB memory interface and Ethernet I/F for faster and smoother program transfer. Value added features offer increased reliability in more complex part processing to simplify those more demanding machining challenges.

Kitamura Machinery of USA, Inc., 78 East Century, Wheeling, IL 60090, 847-520-7755 Fax: 847-520-7763, info@kitamura-machinery.com, www.kitamura-machinery.com.

HIGH-ACCURACY ELECTRODE AND DIE/MOLD MACHINING

Makino, Inc. (Mason, OH) offers the V22 graphite vertical machining center, designed for both precision electrode production and high-accuracy die/mold component machining. “The V22 graphite offers the rigidity and speed necessary to produce tight-tolerance geometries for today’s most complex electrode and hard metal mold applications,” said Bill Howard, Makino product manager. “The machine’s 40,000 rpm spindle offers superior finishing capability and is ideal for intricate, small tool work — enabling machining of high-grade electrodes in a short time.”

In addition to its efficient machining of graphite workpieces, the wide-ranging spindle design offers capability for machining a variety of hardened materials typical of the die/mold market. The V22 graphite is also outfitted with the Professional 5 control and the latest iteration of Super Geometric Intelligence (SGI.4) software for the highest level of precision and lowest cycle times achievable in complex geometries, cavities and cores. The V22 offers a standard 11.3 hp, continuous 40,000 rpm spindle that is complemented by patented core cooling and under-race lubrication system that controls spindle thermal distortion and has proven essential for optimal high-performance applications.

The X-axis of 12.6 in (320 mm), Y-axis of 11 in (280 mm) and Z-axis of 11.8 in (300 mm) operate in a work zone and table size of 17.7 in by 13.8 in (450 mm by 350 mm). The slideway design provides for a 787 ipm (20,000 mm/min) rapid traverse and 394 ipm (10,000 mm/min) cutting feed rates. The Z-axis is designed without any overhang to ensure superb accuracy over the entire range of travel. The V22 can handle a 220 lb (100 kg) load and maximum 17.7 in (450 mm) by 18.7 in (475 mm) by 7.8 in (200 mm) workpiece. The machine features an HSK-E32 spindle interface with a standard 30-tool automatic tool changer with a larger 60-tool-changer option.

The V22 measures 4.9 ft by 6.5 ft (1,500 mm by 2,000 mm) and all setup work is concentrated within the machine’s front width of 4.9 ft (1,500 mm). A fully enclosed splash-guard and powerful dust collector completely seal the entire machining area to prevent graphite dust from escaping, for a clean shop environment. In addition to efficient graphite machining, the V22 will also handle machining of steel and hard metals characteristic of most die/mold shops. Its integrated splash-guard door and ceiling enable easy handling of large workpieces. The door and ceiling open together for trouble-free access to the table with an overhead crane. An optional automatic work changer or multi position robot pallet system allow for long-term continuous automatic operation.

The Professional 5 control uses a Microsoft Windows CE operating system that offers a stable, secure platform with reliable performance on the NC side, while providing an operator-friendly graphical user interface (GUI). This latest-generation machine tool control features large, color, touch-sensitive, on-screen, menu-driven applications. Icons serve as “hot links” and enable quick access to critical information that may be required by the operator. In addition, the new control platform provides all of the functions typical of a PC (cut, paste, copy, find, replace, etc.) that are rarely available on a machine tool control. Advanced data management technology and the proprietary, next-generation SGI.4 servo control deliver the lowest cycle times achievable by reducing machining cycle times on dies, complex cavities and cores by as much as 40 percent when compared to most other control technologies.

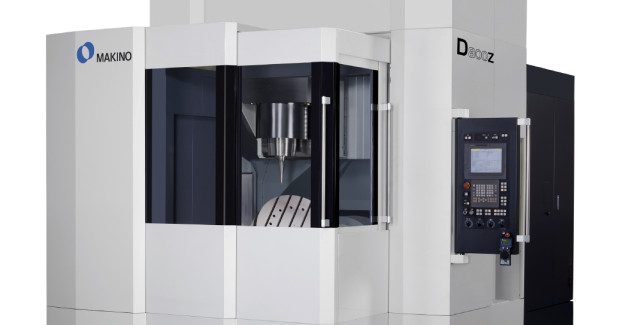

Makino also offers the D800Z 5-axis vertical machining center designed for high-performance job shops, precision parts machining, die mold and aerospace applications. The D800Z has easy access to the spindle and table, a highly rigid structure for responsive cutting, outstanding surface finishes and optional automation devices. Workpieces of up to 1,000 mm diameter and weighing 1,200 kg can be machined in five axes, with great efficiency and fewer operations for reduced production time. “Large-part 5-axis machining presents numerous challenges, due to the size, weight and range of features found on large components,” noted Howard. “The D800Z 5-axis machine provides new levels of sustained dynamic accuracy, achieved through technologies that are very productive, yet minimize thermal influences and maximize volumetric accuracy.”

The 5-axis capability of the D800Z can be utilized in five-face milling mode to minimize setup, maximizing access to complex, multisided parts and reducing cycle times, or to address the demanding angular, blending, matching, fine-surface finishes and 3D accuracy requirements of die-and-mold components. Its integral, direct-drive motor design of the fourth and fifth axes and highly rigid supporting machine structure deliver productive speed and smooth motion, and ensure outstanding accuracy — even with large workpieces and payloads up to 1,200 kg. Core-cooled ballscrews, temperature control of the direct-drive motors and massive machine structure provide renowned thermal stability that guarantees sustained accuracy over time.