Waterjet Used to Build Solar Car

A Jet Edge 5-axis waterjet cuts fiberglass composite chassis components for the Eos solar car.

Posted: June 23, 2015

Waterjet systems manufacturer Jet Edge, Inc. (St. Michael, MN) recently helped the University of Minnesota Solar Vehicle Project (UMNSVP) by waterjetting several fiberglass composite chassis components for the team’s new car, “Eos.” The company is one of several Minnesota companies helping the student solar car team design and manufacture its two-person Cruiser Class car that will compete in the 3-day Formula Sun Grand Prix track race at Circuit of the Americas in Austin, TX, in July and the 3,000 km (1,877 mile) World Solar Challenge in Australia in October.

The 40-member student-run team has been working on Eos for a year and a half and plans to unveil it sometime in early July, said team engineer Jacob Herbers. Until then, all design improvements are being kept under wraps. Eos is the UMNSVP’s 12th car since the project’s inception in 1990. The project has raced numerous times in both the American Solar Challenge and the World Solar Challenge. Over the years, the project’s teams have placed either first or second 15 times and have travelled to Canada, Australia, Japan, and Taiwan.

The project has given students invaluable real world experience as they are responsible for designing, funding, building, testing, and racing each vehicle. It also has helped advance solar technology by serving as an innovation test bed, and has helped advance electric motor technologies, paving the way for today’s successful electric car companies.

The project has benefited from the tremendous support of Twin Cities businesses, noted Herbers, who recently completed his undergraduate degree in mechanical engineering. “There are hundreds of different parts in the car, including the carbon composite outer shell, the carbon and fiberglass composite chassis panels, aluminum and steel mechanical components, solar cells, electric motors and controllers, lithium-ion batteries, electrical wiring, etc.,” he explained. “Our project would be impossible without the help of local manufacturers, who have helped us with layups, laser cutting, tube bending, CNC milling and lathing, heat treating, soldering and waterjet cutting.”

Herbers explained that the car’s chassis components and other parts are cut from as light of material as possible to help the car achieve faster speeds. The team’s previous car topped out at 80 miles per hour. “The finished weight is estimated to be 500 lb,” he said. “Every added lb of weight on the car would cause us to have to drive slower in the race.

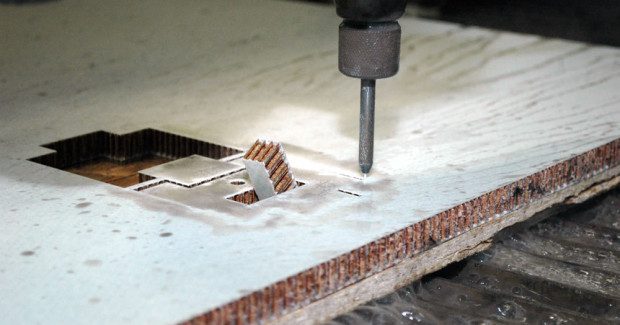

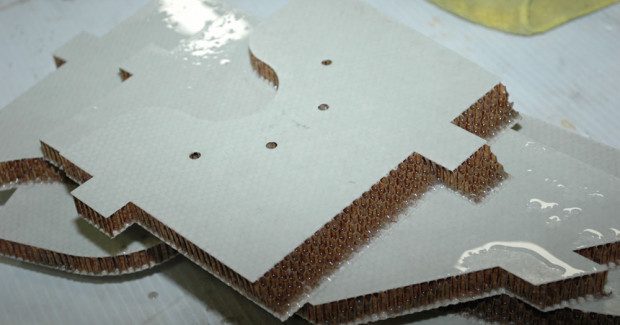

Jet Edge’s role in the project was to cut 14 parts from a 0.53 in thick composite material that consisted of a layer of fiberglass on either side of 0.5 in thick aramid honeycomb core. The waterjet manufacturer cut the parts in its St. Michael test lab, using its latest EDGE X-5® 5-axis waterjet cutting system.

Prior to cutting the parts, company R&D engineer Michael Wheeler and machinist Brian Wallace worked with the team to create DXF files from 3D files supplied by the students. They then used IGEMS waterjet CAD/CAM nesting software to produce the complicated bevels and to create the CNC programs. While the parts were already nested by the team, Wallace fine-tuned the nesting using IGEMS to save material.

“We cut the parts at 78,000 psi using a 0.010/0.030 orifice/nozzle combination,” said Wallace. “We used 0.4 lb per minute of 80 grit garnet abrasive. We cut the holes at 10 ipm and the external shapes at 60 ipm. We adjusted the speed down appropriately for the bevels cuts. We only had one sheet of material to work with, so we utilized our nesting software to get the most parts out of that sheet. It took about 30 minutes to cut all 14 parts.”

“This was first time I’ve cut a honeycombed composite material with the 5-axis,” Wallace added. “It worked perfectly. We probably could have cut the part without abrasive, but we didn’t have a lot of material to experiment with, so I decided to use abrasive. The material wasn’t hard, but with the honeycomb and the bevels, you’re cutting through open areas that interrupt the waterjet, and you are cutting through thicker and thinner material as it bevels.”

To Herbers’ knowledge, the team has always used waterjet to cut its composite components. “It is very precise and ensures a good fit when we assemble the chassis panels,” he said. He encouraged other students to get involved in the Solar Vehicle Project. The UMNSVP is open to all University of Minnesota students, regardless of their area of study, he noted. Members can have as much or as little involvement as they want, but everyone works on designing and manufacturing a part of the car and more experienced members hold leadership positions.

“It is very interesting to visit with local manufacturers and see their processes,” said Herbers, who is pursuing a career that will allow him to use his knowledge to save energy and protect the environment. “I’ve learned a lot about how to design parts for manufacturability, and have gotten to see firsthand how parts of different materials get made, which are things that mostly aren’t taught in school, and will definitely help prepare me for a career in mechanical engineering.”