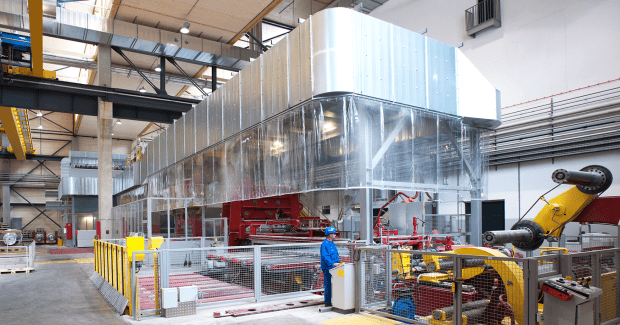

Plansee Invests in New Cold Rolling Mill

The ultramodern cold rolling mill produces thin and medium-thickness molybdenum sheets up to 1,000 mm wide.

Posted: July 7, 2015

Plansee SE (Reutte, Austria) operates the world’s largest hot rolling mill for refractory metals. With a massive rolling force of 50,000 kilo-newtons, this mill produces sheets up to 2,000 mm wide and several meters long.

In order to produce larger sizes of thin and medium-thickness sheets and to ensure increased capacity, the company recently invested in an ultramodern cold rolling mill, the second largest single investment in the company’s history. It is used to produce molybdenum sheets of up to 1,000 mm wide.

This increased capacity means that Plansee is capable of manufacturing large quantities and formats very quickly. The improved quality characteristics and the even greater availability of products present important benefits to customers. “It is not only the quality of the products and the delivery time that is important to our customers, it’s also the price,” explains Andreas Feichtinger, who is responsible for sales and marketing. “This is precisely why we pass cost savings on to them.”

Whether smooth or etched, for punching or in deep-drawing quality: a wide range of sheets is now available at a reduced price in the company webshop. The sales organization is also happy to deal with inquiries for dimensions that are not available on the webshop.

The webshop is not only limited to sheets, however. The company also sells rods, wire and ribbon made from molybdenum, tungsten, tantalum and niobium at shop.plansee.com. Online customers will also find TIG welding electrodes and spare parts for high-temperature furnaces.

Plansee materials withstand high temperatures, have long service lives and retain their shape even when exposed to frequent changes of temperature. Aside from semi-finished products, Plansee also develops and manufactures custom components from refractory metals.