WESTEC 2015

The premier manufacturing event on the West Coast returns to the Los Angeles Convention Center on September 15-17. Take a look at some of the machinery, tooling, systems and accessories that will be exhibited that can help solve your most pressing problems, improve your productivity and increase your profits.

Posted: August 11, 2015

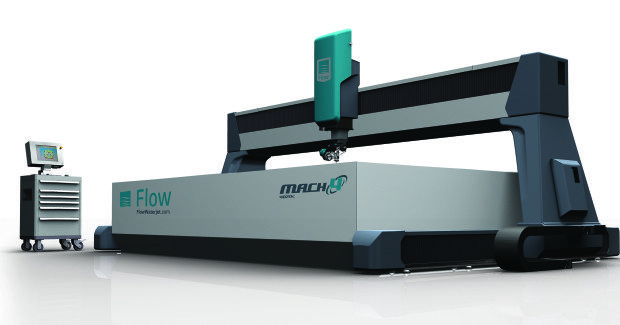

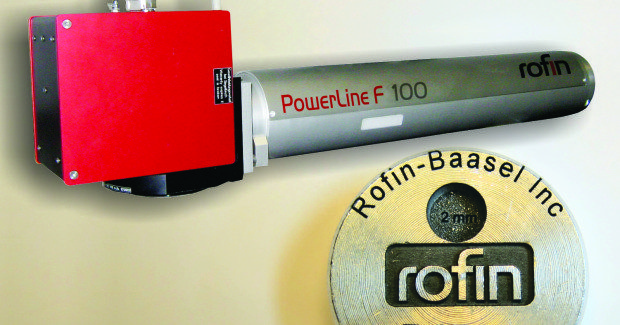

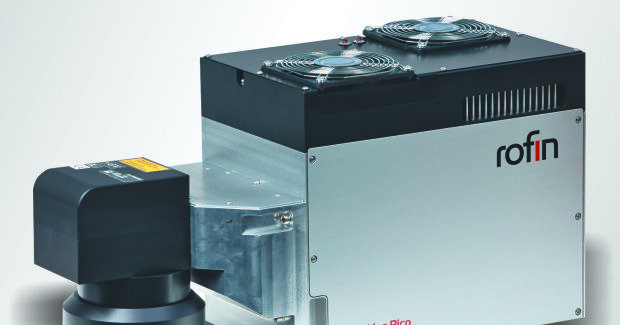

WESTEC brings you the very latest technologies, from software, cutting tools to multi-tasking machines, all from top international equipment manufacturers. At this show, you can learn how to cut your shop costs, enhance quality, or earn a place on an OEM preferred supplier list. This is where collaboration starts as a place to network, form relationships, build partnerships, and solve your most pressing manufacturing problems. There will be over 400 exhibits representing over 1,000 product lines that feature advanced machining, lasers, tooling and fixtures, software, design, automation, quality, 3D scanning, waterjet cutting, 3D printing and more. Here are some reviews of selected machinery, tooling, systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

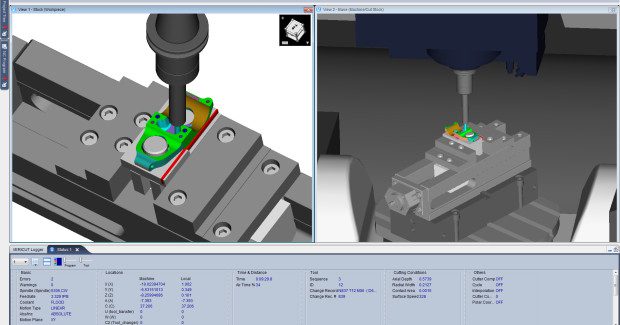

WORLD CLASS MACHINING OF SMALL BATCHES, COMPLEX GEOMETRIES

In Booth 1523, EMAG, LLC (Farmington Hills, MI) will feature manufacturing systems for precision metal components with the North American premier of its new VM spindle down machine platform for the low-cost production of small batches and complex geometries. Part of the large family of EMAG modular machines, the VM 9 vertical turning center combines a reliable platform with an extensive range of equipment. Designed to machine chucked components with a maximum diameter up to 450 mm, it features a tool turret which can be fitted with up to twelve tool positions and can be equipped with driven tools to carry out drilling or milling operations. An integrated probe delivers absolute process reliability by ensuring continuous quality control of the workpieces, making the VM 9 extremely well equipped for a wide variety of production tasks, enabling it to produce a wide range of workpiece formats.

https://youtu.be/4erawIId5NQ

The VL series will also be on display for visitors to experience the successful EMAG modular inverted vertical lathe design. With the aim to develop a system of modular machines ideal for use in the manufacturing of medium and large batch runs, one common feature of all four machine sizes is the shared basic, compact design. Their small footprint means reduced floor space costs and flexibility in machine layout (for example, Chaku Chaku or closed loop arrangement). Every VL machine features an integrated O-automation system for transporting workpieces. When combined with the self-loading pick-up spindles, this automation concept ensures short cycle times and high productivity. To accommodate machine operators, all the service units are easily within reach, with the various units (electrics, hydraulics, cooling system, cooling lubricant and central lubrication system) accessible at any time so that the machines can be maintained with ease.

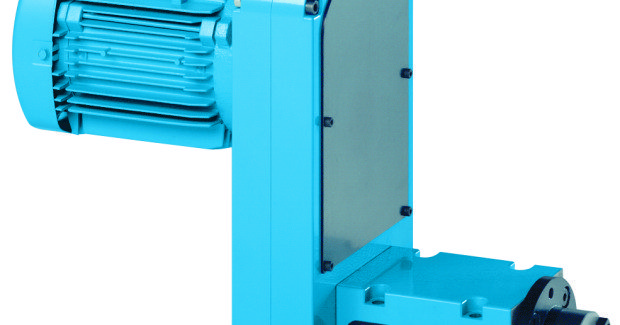

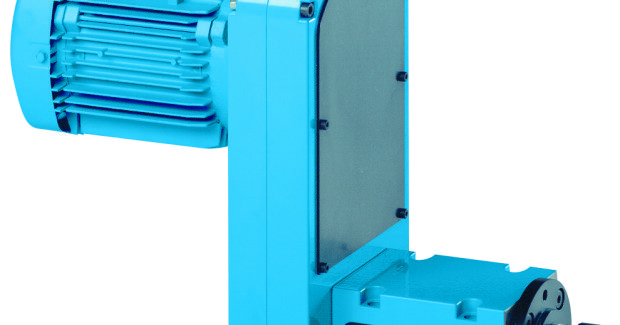

The group technologies in EMAG Holding GmbH (Salach, Germany) cover the entire spectrum of metalworking, including non-traditional processes. Electro-Chemical Machining (ECM) is used in the aerospace sector for the manufacture of blisks, while laser welding is essential in lightweighting automotive components. Introducing the latest addition to this technology portfolio, EMAG eldec Induction USA (Auburn Hills, MI) will display a modular induction (MIND) hardening system at the show that features Simeltaneous Dual Frequency (SDF) technology to compliment the workpieces machined by EMAG lathes and create efficient, complete production lines. These flexible machine concepts and complete systems offer modular and customized solutions for the production of workpieces in nearly every industry.

EMAG LLC, 38800 Grand River Avenue, Farmington Hills, MI 48335, 248-442-6719, Fax: 248-477-7784, kkilgore@emag.com, www.emag.com

VERSATILE CUT-OFF SAW

In Booth 2751, MetalMizer (Indianapolis, IN) will display the MV2018 Vertical Bandsaw, a versatile cut-off saw that offers a large 18 in x 20 in cutting capacity and up to 175 lb of cutting pressure. This high-quality production saw provides many operator-friendly features including a counterbalanced tilting saw head which is easily adjusted by one person for 45 deg cuts in either direction without having to swing or move cutting material. Pre-stop indents are located at both 45 deg angles and the vertical positions for faster head adjustment by the operator.

All controls for the MV2018 are conveniently located above the working surface on the face of the cutting head making them easily accessible and safe from being damaged by work pieces, cutting fluids, and debris from the cutting operation. The overhead controls allow one-button activation of the blade, coolant, and feed mechanism or the flexibility to control each function individually. Variable blade speed is also adjusted from the front panel and can easily be fine-tuned during a cut with power or hand feed options. With the motor drive system mounted directly on the cutting head, overall machine depth of the MV2018 is 30 percent less than competitive saws with the same cutting capacity.

Established in 1985, MetalMizer metal cutting saws are trusted by manufacturing companies around the world to fulfill fabrication, production, maintenance, and R&D needs.

MetalMizer, 8180 West 10th Street, Indianapolis, IN 46214, 800-522-5097, info@metalmizer.com, www.metalmizer.com.

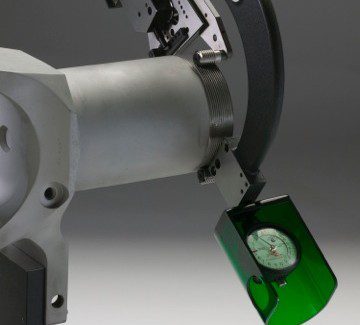

PRECISION BORING OF ENORMOUS RANGE WITH JUST ONE HEAD

In Booth 1035, the new EWN 2-50XL Boring Kit from BIG Kaiser Precision Tooling Inc. (Hoffman Estates, IL) now offers a turnkey precision boring tooling solution for the entire diameter range of Ø.700 in to 6.000 in. To make this new range possible with just one boring head, company engineers came up with a new, rigid, dynamic center-mounted boring bar/insert holder capable of maintaining consistent precision throughout its full range. Previously, center-mount boring bars were used to cover a max Ø2.125 in, and an outboard insert holder clamped to the side of the head covered Ø3.150 in to 6.000 in. This left a significant gap of over Ø1 in that could not be covered, and an additional head from the 310 series was needed to fulfill the full bore range to Ø6 in. As a result, this new kit saves users nearly $2,000 when compared to the previous generation kit.

https://youtu.be/MdYMrd2WaUI

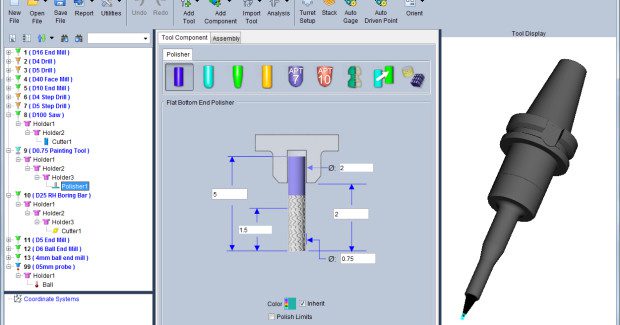

The tooling and carefully selected accessories come stored in a molded plastic carrying case with foam inlay to keep the components organized and protect the instruments when not in use. Each kit includes:

- (1qty) Series 112 EWN 2-50XL finish boring head

- (2qty) Center-mount steel boring bars & corresponding screw-on insert holders for Ø.700 in to 3.150 in

- (3qty) Outboard insert holders for Ø3.150 in to 6.000 in

- (1qty) Coolant nozzle

- (1qty) 10-pack of carbide coated TC11 inserts with a .016 nose radius (for general steel and cast iron)

- (2qty) Wrenches

The EWN 2-50XL boring head features adjustments of Ø.0002 in/div. Coolant through is standard with a max pressure of 300 psi. When using the outboard insert holders, an included coolant nozzle inserts to the center of the head for direct coolant delivery to the cutting edge. The same outboard insert holders can simply be assembled in reverse to permit back boring. If needed, the system is expandable for deep hole boring with carbide bars and diameters as small as .080 in, and additional accessories can be ordered for super-fine balancing, OD turning and chamfering.

BIG Kaiser Precision Tooling is a leader in high precision tooling systems and solutions, with brands including BIG Daishowa, KAISER, Speroni, Unilock, Sphinx and more that focus on extreme accuracy and repeatability. BIG Kaiser’s mission is to support North American manufacturers with products that are designed and manufactured to a superior standard. Guaranteed.

BIG Kaiser Precision Tooling Inc., 2600 Huntington Boulevard, Hoffman Estates, IL 60192, 847-228-7660, Fax: 847-228-0881, bigkaiser@bigkaiser.com, www.bigkaiser.com.

SMALL DIAMETER DISC BRUSHES FOR HARD TO REACH APPLICATIONS

In Booth 2309, the high performance abrasive nylon disc brush line from Brush Research Mfg. Co. Inc. (Los Angeles, CA) has expanded to include a selection of small diameter tools. The new brushes are available in 50 mm, 60 mm and 80 mm in both the Dot and Turbine style configuration. A new specialty flow through tool holder with a 16 mm shank is also available to accommodate these smaller diameter tools. Nampower brushes are made of a combination of ceramic and silicon carbide abrasive nylon mounted to a thermoplastic base. These smaller diameter disc brushes will offer greater versatility into harder to reach areas, smaller applications and planetary head mountings. Create reliable, consistent and cost effective results. Nampower Disc Brushes are easily integrated into today’s automated machinery, CNC machining centers, transfer lines and robotic cells. The best just got better.

Brush Research Mfg. Co. Inc., Los Angeles, CA 90022, 323-261-2193, Fax: 323-268-6587, sales@brushresearch.com, www.brushresearch.com.

METAL FABRICATION SOLUTIONS

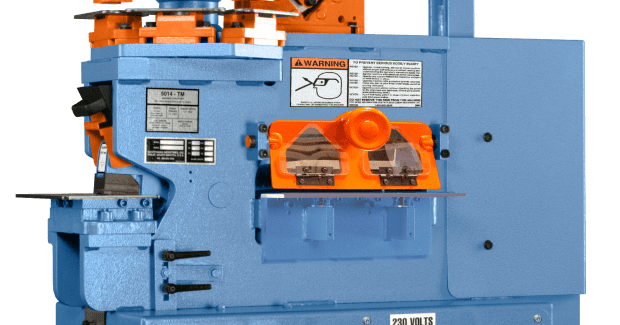

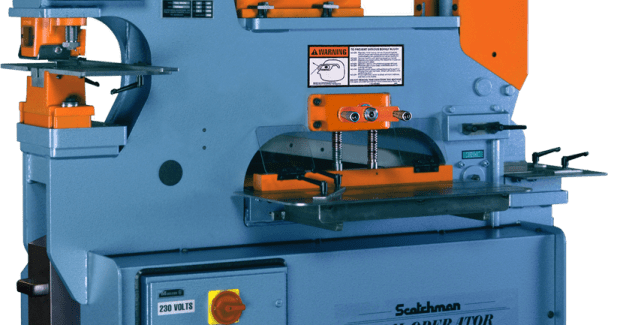

In Booth 2211, Scotchman Industries, Inc. (Philip, SD) is excited to be demonstrating a few select pieces of their line of metal fabricating solutions. Featured ironworkers will be their 50 ton turret, 5014TM, and dual operator model DO95. The 5014TM offers a three-station revolving turret, which accepts up to three pieces of tooling that can be changed in seconds. This machine has 50 tons of pressure and can punch a 13/16 in hole in a ¾ in plate. Standard features include angle shear, flat bar shear, and a rectangle notcher.

The DO95 dual operator ironworker from Scotchman has a hydraulic system designed with two pumps to ensure both operations have full hydraulic pressure and speed, complete with two valves, two stroke controls and two remote foot pedals. It has a 95 ton capacity punch and a 9 in throat depth, which can punch a 1-3/16 in hole through 1 in material. The DO95 complements Scotchman’s existing dual operator ironworker line, which consists of punch capacities ranging from 70 tons to 150 tons. All of these ironworkers are American made and backed by a three-year warranty.

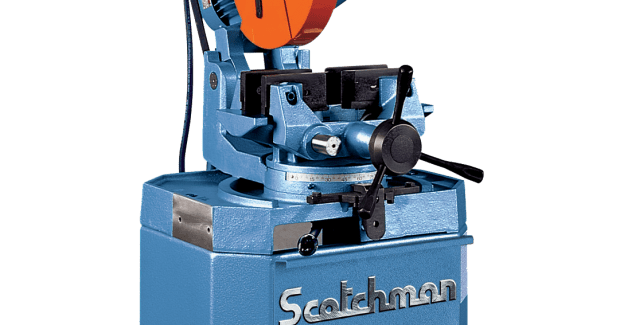

Representing their cold saw line will be the manual CPO 350 saw and a newly added upcut saw, the SUP 500 NF. The American-made CPO 350 manual Circular Cold Saw features a double clamping and self-centering vise that provides burr-free, high quality, volume parts. A must in any shop, the SUP-500 NF is an Upcut Circular Cold Saw designed specifically for cutting non-ferrous material. Featuring a 20 in carbide blade that is capable of producing round cuts up to 7 in diameter and rectangular cuts up to 11.75 in x 5 in, this machine offers an increased cutting capacity not found in similar Scotchman models.