WESTEC 2015

The premier manufacturing event on the West Coast returns to the Los Angeles Convention Center on September 15-17. Take a look at some of the machinery, tooling, systems and accessories that will be exhibited that can help solve your most pressing problems, improve your productivity and increase your profits.

Posted: August 11, 2015

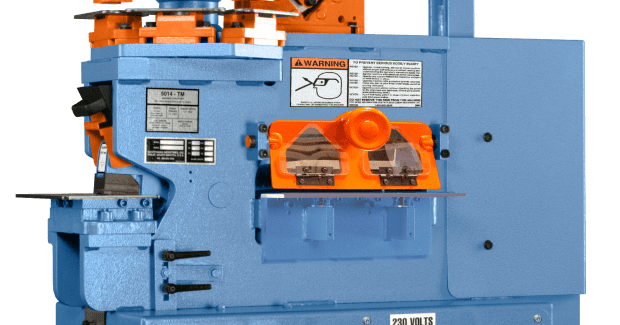

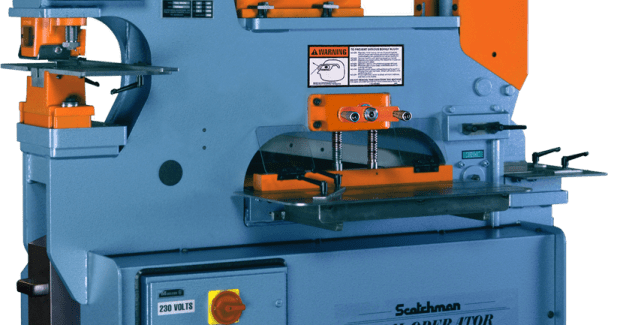

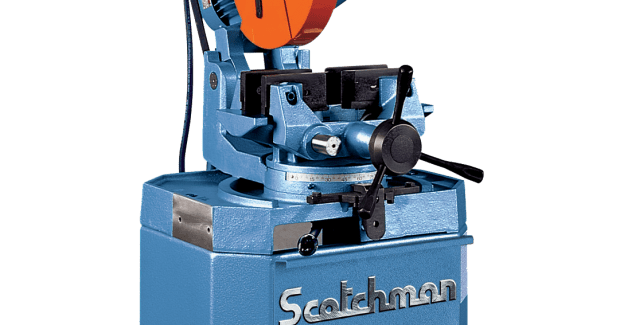

Scotchman Industries was founded in 1967 and has been providing quality materials and construction, dependable performance, competitive pricing, and service to its consumers ever since. As the world and its markets change and expand, Scotchman continues to grow and adapt.

Scotchman Industries, Inc., 180 E. Hwy 14, PO Box 850, Philip, SD 57567, 605-859-2542, Fax: 800-843-5545, info@scotchman.com, www.scotchman.com.

EASILY MOVE AND PLACE HEAVY LOADS IN TIGHT SPACES

In Booth 2255, the compact and flexible Air Caster Rigging Kit from AeroGo, Inc. (Seattle, WA) contains everything necessary to move heavy, awkward or delicate loads using compressed air. The Kit is housed in a rugged and lockable storage box. The rigging kit system can be configured to accommodate numerous and varied load requirements in a variety of applications, handling load weights as heavy as 64,000 lb. Each Rigging Kit is simple to operate and extremely flexible. It is designed to utilize compressed air through air casters. Air casters offer superior load distribution by distributing the load weight over a much greater surface area than rollers or wheels, eliminating floor surface damage and the need for reinforced floors. Load movement is smooth and omni-directional, making it easy to precisely place heavy loads – even in tight spaces.

Rigging Kits can be utilized in any work environment where there is adequate floor surface and compressed air is available. These kits include all of the components required to rig and move heavy loads in an industrial environment. Each kit includes four Aero-Caster load modules to lift and float heavy loads, a control console to regulate air to the modules and compensate for uneven loads, four 20 ft color-coded air hoses with quick-disconnect fittings, aluminum tape to temporarily repair minor floor imperfections, an operations manual and a rugged, lockable storage box to ensure system integrity.

Founded in 1967, AeroGo is a world leader in providing standard and customized load moving solutions for highly sensitive and exceptionally heavy loads.

AeroGo, Inc., 1170 Andover Park West, Seattle, WA 98188, 206-575-3344, Fax: 206-575-3505, info@aerogo.com, www.aerogo.com.

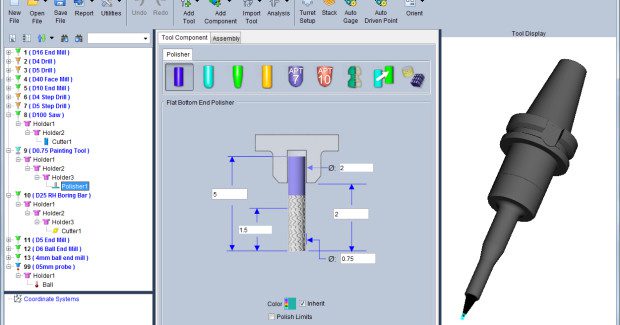

PRODUCTIVE MACHINING TECHNOLOGIES

In Booth 1334, Chevalier Machinery, Inc. (Sante Fe Springs, CA) demonstrates six magnificent machines, with extremely knowledgeable engineers to answer application questions. The machines demo cutting at the show include the new EM2033L VMC, QP2443 VMC, FBL-300 MC and FBL-200 lathe. The Smart-B818III profile grinder and the FSG-1224ADIII fully automatic grinder will be running cycles cutting air. Here is the machine lineup at the show:

The new EM Series delivers more bang for the buck. Pricing peaks at $59,800 on this high-speed vertical machining center, which offers a cost savings that hammers the competition through increased shop production capabilities. The EM Series is engineered with efficiency to satisfy the need for large quantity machining with limited floor space. Choose from three models: EM1620L, EM2033L and EM2040L. Prices start at only $48,500 for the EM1620L. Nothing is sacrificed or compromised in the EM Series. The major parts of this machine are constructed of high-quality Meehanite cast iron, which offers superior stability. The machine base is supported by full-travel, enabling it to be suitable for high-speed machining. All three axes are built with high-speed linear ways providing smooth quick movement without delay.

The EM Series provides fast interpolation, minimizing machining time with high, rapid speed, up to 1,889.7 ipm. All three axes are driven by preloaded P3 ballscrews and super-fast linear ways. The powerful 20 hp spindle motor handles up to 10,000 rpm, producing an attractive finish surface in high-speed with enough torque in lower rpm. Tool capacity is up to 24 tools with a random tool double arm tool change. The series is loaded with features: FANUC 0iMD; color 8.4 in LCD that has simultaneous contouring; linear-circular-helical interpolation and canned cycles for drilling, tapping and profiling, all with FANUC drives and motors. Plus, a two year FANUC warranty.

The pricing on the newly designed FBL-200 slant bed lathe with box ways starts at $59,950. It boasts a 45 deg slant-bed rigid box ways structure and ribbed Meehanite cast iron mono-blocking casting that provides strong support and excellent damping absorption that help resist deflection and vibration during heavy machining. The FBL-200 is engineered with ease of access and trouble-free maintenance in mind. Its compact design minimizes floor space. This is the best machine in the market for mixed volume, short-run or dedicated high-volume applications. The FBL-200 slant bed lathe features an 8 in chuck, 18.5 in maximum swing diameter with 10.2 in maximum turning diameter and a maximum turning length up to 16 in. The lathe runs up to a 20 hp AC digital spindle motor. The spindle bar capacity is 2.55 in diameter and speeds up to 3,500 rpm. The 10 station turret offers fast tool indexing. Model comes with a powerful FANUC 0i-TD control and digital servo drive and motor. This new control provides the most popular functions, including a rigid tap, multiple threads and a conversational Manual Guide 0i program.

The 50-taper QP2443 heavy-duty box way vertical machining center has an excellent box way structure that is designed for heavy duty machining. The 30 hp machine has a two-speed gearbox that provides powerful cutting capability. Shops have praised this machining center for its rigid structure, high precision and greater productivity with heavy workpieces. The machine table size is 49 in x 25.6 in with a table load of 2,640 lb. XYZ travel is 43 in x 24 in x 25 in. It is perfect for cutting stainless steel, forgings or any material with hardness over Rc50.

https://youtu.be/RiuwBIjUh8I

The newly designed FBL-300 MC lathe boasts a 45 deg slant-bed rigid box ways structure with live tooling. Its ribbed-Meehanite, cast-iron, mono-blocking fabrications provides strong support and excellent damping absorption that help resist deflection and vibration during heavy machining. The machine features a 10 in chuck, a 25.7 in maximum swing diameter with a 20 in maximum turning diameter and a maximum 30 in turning length. The FBL-300 MC includes a 25 hp, AC digital spindle motor; the spindle bar is 3.03 in diameter and at a speed of 2,500 rpm. The live tooling provides powerful milling, drilling and tapping functions. The German Sauter 12-station, live turret offers 0.24 secs tool indexing (next tool). The standard auto-tool-setter system helps to reduce set-up time and keeps non-machining time to a minimum. The standard programmable tailstock comes with automatic positioning capability, along with a programmable quill. The standard chip conveyor provides efficient chip management. The model comes with a powerful FANUC 0i-TD control and digital servo drive and motor. The new control provides the most popular functions, including a rigid tap, multiple threads and a conversational Manual Guide 0i program.

The new SMART-B818III fully automatic grinder is capable of producing “mirror” surface finishes on highly accurately ground workpieces that result in microfinishes of 5 RMS. The positioning accuracy is 0.0025 mm and the grinding accuracy is 1 micron. The SMART’s movements are programmable in increments of 0.001 mm on a table size of 8 in x 8 in. The maximum distance from table to spindle centerline is 18 in. The wheel spindle is rated at 500 rpm to 7,000 rpm and 3 kW (4 hp) with a standard grinding wheel size of 8 in x .5 in x 1.25 in. The machine weighs approximately 2,665 lb with overall dimensions of 80.9 in x 82.36 in x 82.7 in. Its PC-based control, combined with a user-friendly conversational TaskLink and constant contact dressing function, makes it easy to learn and operate.

The new FSG-1224ADIII Series surface and profile CNC grinder is a highly advanced, automatic-precision, surface grinding machine that offers improved accuracy, quality and ease of operation. This series includes the new touch-screen control station that is adjustable to a comfortable position for the operator. Switches, buttons, LEDs and indicating lamps are all combined in a touch display that is ergonomically positioned to provide the best user-friendly operation. The FSG-1224ADIII Series includes a new PLC controller that provides a grind cycle with rough grinding, fine grinding, spark-out passes and an automatic over-wheel dresser with compensation, which can be added to fully automate the grind process. After the cycle is finished, the table will “park” either left or right of the saddle and at the front to facilitate unloading and loading. The spindle can be set to “stop running” or “continue running.” The wheel head can also be set to return to the start position or to park at a reference point. Once the cycle is started, the wheel head will move rapidly to the start point and repeat the grind cycle. If material is required to be removed from both sides, “flip over” can be selected, so the wheel head position is at the finished grind height, which immediately commences grinding without touching off.

Chevalier Machinery, Inc., 9925 Tabor Place, Santa Fe Springs, CA 90670, 562-903-1929 ext 128 (turning and milling machines), ext 126 (grinding machines), Fax: 562-903-3959, www.chevalierusa.com.

HORIZONTAL BANDSAW FOR HIGH PRODUCTION OR JOB SHOPS

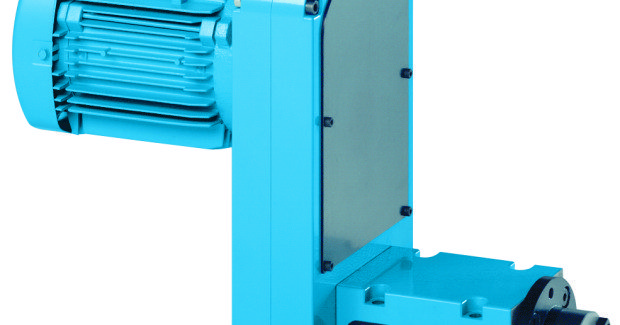

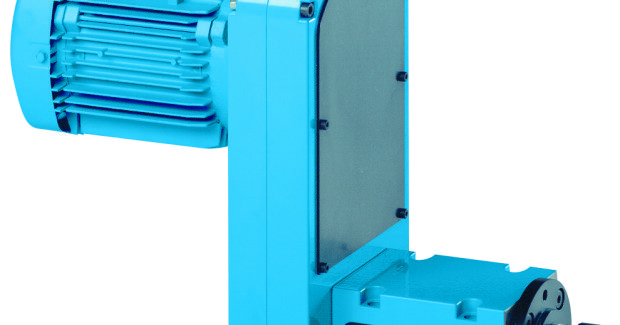

In Booth 2223, Behringer Saws, Inc. (Morgantown, PA) a manufacturer of high-quality bandsaw, circular and plate sawing solutions, introduces the HBE Dynamic Series Horizontal Bandsaw, a versatile, compact automatic saw that features an array of leading-edge functions designed to improve performance and precision while maximizing user convenience and safety. “Ideal for a wide range of application environments from production cutting steel service centers to metalworking job shops, we have positioned the HBE Dynamic as our affordable “everyday” bandsaw with a full complement of innovative, performance-enhancing features,” said Richard Klipp, the president of Behringer Saws.

Among the innovative range of features on the HBE saw is a servo-driven precision downfeed control that automatically adjusts blade pressure, creating an optimal balance of feed rate and pressure for improved quality and cutting rates, while extending blade life. And an electrically powered ball screw driven material feed gripper to eliminate backlash and ensure precise material positioning for improved accuracy. HBE Series saws also feature an optional automatic feed control (AFC) that automatically adjusts cutting parameters such as blade speed and downfeed rate to the material grade and shape. This permits operators to create flexible material programs leveraging cutting data based on specific material grade. Additionally, a fault/ alert history may be viewed at any time by the operator. The detailed information displayed in plain text is useful for both planning and analysis of past projects.

As with all Behringer bandsaws, the cast iron dual column construction of the HBE saw frame provides exceptional rigidity, eliminating stress, reducing vibration and enhancing blade tension. Two linear ways and four guides facilitate precise and accurate vertical movement of the blade. Cutting accuracy is further enhanced by the horizontal band arrangement and hydraulically tensioned blade, and double roller bearings for the blade guiding. HBE saws utilize a high torque, state-of-the-art frequency-controlled blade drive which requires low power consumption, yet produces the blade power and speed needed for fast cutting and peak throughput rates. The enclosed HBE design promotes safe operator use, stays clean and minimizes noise while providing a large observation window. And an intuitive NC control system enables user-friendly operation.

The HBE Dynamic saw is available in four models: 261A, 321A, 411A and 511A. The HBE cutting range is from 10.2 in to 20.0 in diameter for round stock and from 11.8 in x 10.2 in up to 20.0 in x 20.0 in for flat stock. Stroke length is 25.6 in and blade speed ranges from 50 fpm to 350 fpm.

Behringer Saws, Inc., 721 Hemlock Road, Morgantown, PA 19543, 888-234-7464, www.behringersaws.com.

AIR POWERED PIPE BELT FINISHER

In Booth 923, Dynabrade, Inc. (Clarence, NY) is proud to introduce the new air-powered 14360 Pipe Belt Finisher that is ideal for blending and finishing applications on metal, stainless steel and a variety of other materials. This tool can be used on pharmaceutical equipment, food machinery, railing and other metal fabrication applications. The 14360 Pipe Belt Finisher uses abrasive belts ½ in to 1-1/2 in wide x 30 in long. The tool is ideal for blending cylinders, sanding castings, cleaning welds and fabricating metal, and is also excellent for blending and polishing tubing and round stock, finishing structural steel and various blending applications.