WESTEC 2015

The premier manufacturing event on the West Coast returns to the Los Angeles Convention Center on September 15-17. Take a look at some of the machinery, tooling, systems and accessories that will be exhibited that can help solve your most pressing problems, improve your productivity and increase your profits.

Posted: August 11, 2015

The design of the tool allows for 180 deg of work piece abrasive capture at any time. The slack of the abrasive belt allows for use on various sizes of pipe. Utilizing both coated and non-woven belts, the tool features a tension arm which allows for quick belt change. Both the belt housing and side handle are adjustable for operator comfort. Utilizing a .7 hp air motor, the tool runs at 3,400 rpm. No-obligation demonstrations are available. Made in the USA.

Dynabrade has been supplying quality industrial abrasive power tools for use in industries worldwide for over 46 years.

Dynabrade, Inc., 8989 Sheridan Drive, Clarence, NY 14031-1490, 716-631-0100, www.dynabrade.com.

BREAKTHROUGH WATERJET SOFTWARE

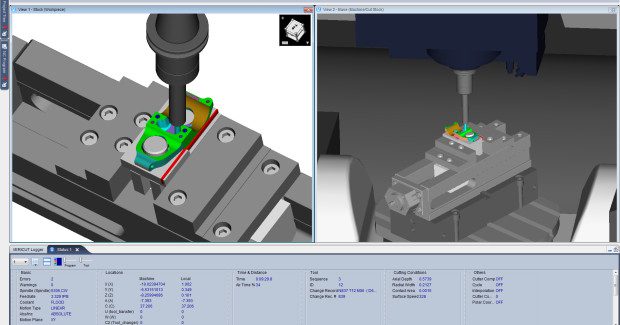

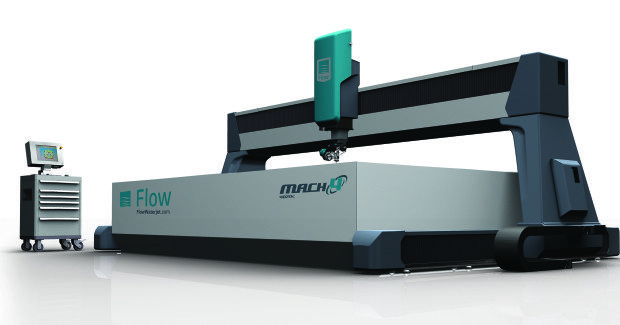

Flow International Corporation (Kent, WA), a leading developer and manufacturer of industrial waterjet machines for cutting applications, will run live demonstrations of their Mach series waterjets in Booth 1503 featuring state-of-the-art technology, including the latest in intelligent waterjet software with FlowXpert® 2015. A Mach 4 waterjet will be running with FlowXpert 2015 next generation 3D CAD/CAM software. The FlowXpert Software Suite is a robust 3D CAD/CAM platform that expands on the 2D FlowMaster® intelligent Software Suite and includes Design powered by SpaceClaim, an integrated 3D modeling tool with Flow Sequencer. With this release, the integrated CAD/CAM capabilities give users a seamless pathing experience. The integration with Flow Sequencer adds flexibility to users and is designed specifically for waterjet cutting, resulting in faster waterjet programming.

The Mach 4 offers a variety of features unique in the waterjet industry including an expandable modular design, up to 14 m (48 ft) in length, allowing shops to increase the size of the cutting area as their business grows. The system’s exclusive roller pinion system provides fast, accurate cutting with zero backlash. The system is ergonomically designed to improve operator convenience and productivity with lighting to enhance work piece visibility, efficient abrasive removal, and easy access to material and parts with full four-sided accessibility. The Mach 4 will combine a HyperJet® pump rated at 94,000 psi, Dynamic Waterjet® XD, high-precision flat stock and 3D cutting technology. The Dynamic Waterjet XD will demonstrate the newest in waterjet height sensing technology, the DynaBeam™ Laser Height Sensing System. DynaBeam is the only non-contact material height sensing solution available in the industry and can be used in combination with Dynamic Waterjet XD for 2D and 3D bevel cutting.

The Mach 2 is a value-priced machine tool optimized for either pure or abrasive waterjet cutting. Whether cutting 3 in thick steel plate or multi-stacked gasket material, the Mach 2 provides fast and accurate cutting at an exceptional price. The Mach 2b will be shown with the new HyPlex® Prime pump which has a highly modular design, allowing customized pump performance at a low production-level price. Application specialists will be on hand to answer questions and demonstrate how Flow’s waterjet technology provides fast and highly accurate cutting across all of our systems.

Flow International Corporation, 23500 64th Avenue South, Kent, WA 98032, 253-850-3500, www.FlowWaterjet.com.

GEARBOX AND TOOLHOLDING SOLUTIONS

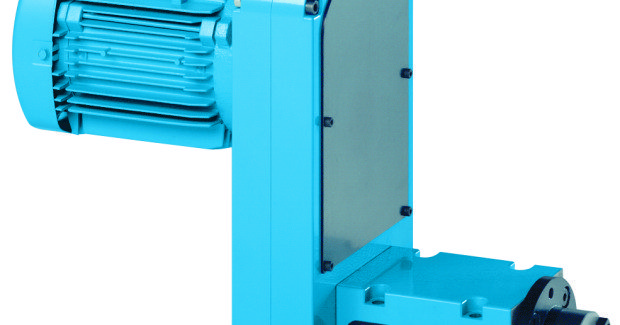

In Booth 1919, Exsys Tool, Inc. (San Antonio, FL) will showcase a wide range of advanced manufacturing technologies. On display will be new gearbox solutions along with toolholding innovations that include the Eppinger brand Compacto™ C3, C4, C5 and C6 base holder system as well as the Preci-Flex® modular quick-change tooling system. Eppinger’s new line of gearboxes are compact and high-transmission capable. Ideal for a wide range of applications, including machinery, automation and robotics, these gearboxes meet strict demands for stiffness, performance and efficiency as well as provide smooth, reliable operation. Visitors at the show will see:

- Bevel gearboxes – a series of compact gear boxes offering increased torque at maximum efficiency for all gear applications requiring a high degree of reliability and variability;

- Hypoid gearboxes – suitable for specific and highly dynamic applications with specially developed mono-bloc housings for extreme stability and maximum precision and efficiency;

- Planetary gearboxes – modular designs and combination of hardened and ground gears with high-precision gearbox components guarantees efficient performance, smooth running and extended uptime;

- Cycloidal gearboxes – highly compact and rigid cycloidal precision gearboxes well suited for drive technology, especially in tool machinery, automation and robotics;

- Customized gearboxes – specially designed to meet customers’ requirements.

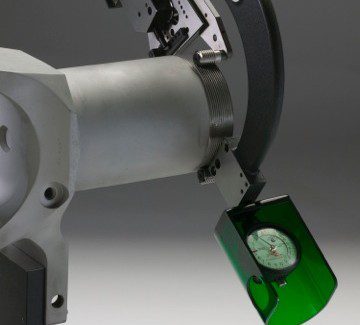

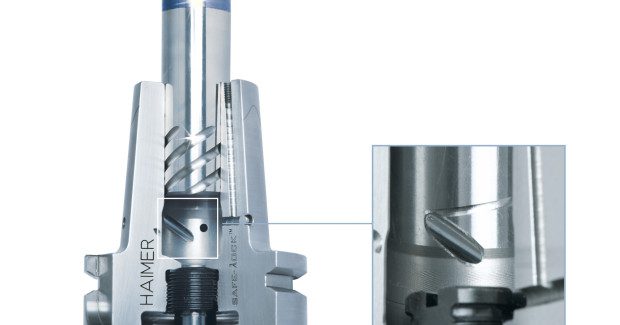

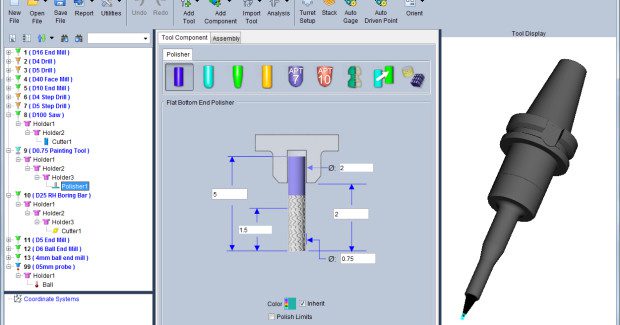

Show attendees will also experience the expansive offering of Exsys high-precision gear technology that entails spiral, hypoid and Zerol gears manufactured with Gleason gear technology. Representing advanced modular quick-change tooling technology at the booth, the Compacto C3, C4, C5 and C6 base holder enhances the efficiency and productivity of CNC turning machines. When compared with traditional base holder designs, the compact size of Compacto provides more space for machining in tight workspaces, as well as offers improved torque transmission and rigidity for increased tool accuracy. The holder’s polygon shape connection (PSC), which is the shortest PSC interface in the industry, further adds to the system’s precision and stability.

A special built-in release mechanism on the outer diameter of the base holder’s spindle provides optimum accessibility. Operators can easily lock and unlock adapters with a small Allen key for fast and virtually effortless tool changes. Plus, the automatic ejection feature of the adapters further increases the speed and efficiency of thosetool exchanges. Available for bolt-on and VDI-style turrets, the Compacto connection base holder accommodates fixed and rotary tools, including the Preci-Flex system, and accepts all standard PSC adapters. In fact, adapters used in milling applications will now work in turning operations, due to the versatility of the Compacto.

During the show Exsys will demonstrate its industry proven Preci-Flex modular quick-change tooling system, which features a selection of adapters engineered to hold different cutting tool and shank designs. The adapters’ common connecting feature locks into a standard base unit on the machine turret, enabling tool/adapter assemblies to be preset offline then quickly switch in and out of the base unit. Tool positions repeat within ±3 µm, eliminating the need to re-center, touch off or make test cuts. The Preci-Flex conical and flat-face planar interface duplicates the taper of the standard ER collet. This enables ER collets, albeit at lesser repeatability, to be used along with Preci-Flex adapters to mount collets, end mill holders, expanding collet chucks and shrink-fit tooling on a single-base holder. Operated at the front face of the turret, the connector provides two tons of clamping force, and its compact design maximizes torque transmission and rigidity, increasing accuracy and productivity.

Exsys Tool, Inc., 11654 Corporate Lake Boulevard, San Antonio, FL 33576, 352-588-4345, Fax: 352-588-4821, info@exsys-tool.com, www.exsys-tool.com.

FIXTURING AND MATERIAL HANDLING TECHNOLOGIES

In Booth 808, Fixtureworks® Workholding Technologies (Fraser, MI), a leading supplier of fixturing accessories, machine tool elements and material handling components, will display a broad spectrum of application-specific solutions using readily available, off-the-shelf products from a single source, including the company’s full lineup of ImaoÒ One-Touch fasteners and One-Touch clamps. Designed for quick, easy and secure changeover and installation without the need for any tools, One-Touch fasteners are poised to replace cumbersome nut-and-bolt assembly in many applications. These pin-and-receptacle fasteners are available in a variety of styles and configurations for attaching fixtures, plates, machine covers and more.

For shops seeking a precision clamping solution for repetitive applications, One-Touch clamps offer easy and efficient clamping and unclamping of a workpiece in one simple operation. By eliminating the need for tools when applying the clamping force, these unique clamps are designed to help reduce setup time and increase productivity. The lineup of One-Touch clamps includes swing, push, pull, retractable, thrust, snap and side clamps in a wide range of clamping force.

Also on display will be Fairlane Products’ full line of grippers, rest pads, Swivots® swivel/pivoting positioning components, quick release ball-lock pins, rollers and bumpers; Kipp® spring plungers, rest and riser pads, levers, handles, knobs, and hand wheels; Imao® supports and stops, risers, T-nuts, sliding mounts, springs, supports, grid plates and blocks; OK-Vise® single and double wedge clamp designs; Mitee-Bite® low-profile edge clamps; and Modern Industries’ mPower™ precision locating and mounting systems; and CMM inspection fixturing sets, as well as premium fixturing components from DK Fixture Systems.

Fixtureworks Workholding Technologies, 33792 Doreka, Fraser, MI 48026, 586-294-1188, info@fixtureworks.net, www.fixtureworks.net.

ADVANCED INSPECTION OF TUBE SHAPES

In Booth 1815, Hexagon Metrology, Inc. (North Kingstown, RI) will introduce the TubeShaper, a result of 30 years of experience in the tube manufacturing sector that has been designed in collaboration with some of the world’s leading producers of tubes to manage all major applications in this area as a single solution for applications related to tube manufacturing and bending, reverse engineering, tube inspection, and tube gauging. TubeShaper has been designed with two graphic user interfaces which can be selected at any time: Engineering Interface, which is designed for shop-floor supervisors and managers. This interface allows access to all of TubeShaper functions. Shop-floor Interface is a more simple user environment that allows access only to TubeShaper’s core functions. This interface features larger icons so that the software can be guided from the ROMER Arm, saving valuable time and trips to and from the computer during measurement.

Spring-back and elongation are also now easier than ever to manage, thanks to a readily accessible library of values which can be applied to any tube at any time. Automatic measurement reporting trends and tube bender performance can be tracked easily, allowing users to spot problems before they become critical.

Tubeshaper is compatible with all RDS compatible ROMER arms: Absolute, Infinite 1, Infinite 2 and Stinger 2ii. It is totally compatible with all non-contact Tube-probes and conventional touch probes, so that tubes of large diameter and geometric features (like flanges and brackets) can be measured in the same software session.

All previous Hexagon Metrology tube measurement file types can also be imported into TubeShaper: SupraVision, DOCS and G-Tube, while CAD models can be imported in iges and step formats as standard (other CAD file importers are available on request). For reverse engineering applications, all measurements can be exported as CAD-friendly iges files, eliminating the need for complex point-cloud handling. TubeShaper v1 can be interfaced directly to the following CNC tube bending machines: SV Network, BLM, Addison McKee Mklll and Eaton Leonard Velog. TubeShaper v1 will be available in: English, French, Spanish, Italian, German, Simplified Chinese, Russian, Japanese and Portuguese.

The company has also released the RS3 upgrade package that delivers a dramatic performance improvement for the ROMER Absolute Arm with integrated laser scanner. The RS3 doubles the scan rate of the previous RS2 integrated scanner, enabling users to inspect parts in approximately half the time. The laser scanner will be available with all newly purchased ROMER Absolute Arm SI portable measurement systems or as an upgrade option for existing customers. The RS3 integrated scanner also delivers greater point cloud density with a maximum acquisition speed more than 9 times faster than its predecessor, resulting in more detailed scanning without compromising accuracy. Users will benefit from the latest RDS proprietary software featuring SMART technology that monitors the arm in real-time and reduces the mean time to repair.