WESTEC 2015

The premier manufacturing event on the West Coast returns to the Los Angeles Convention Center on September 15-17. Take a look at some of the machinery, tooling, systems and accessories that will be exhibited that can help solve your most pressing problems, improve your productivity and increase your profits.

Posted: August 11, 2015

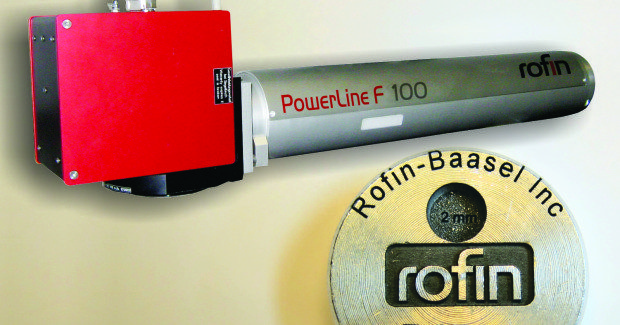

The newest fiber marker, the PowerLine F 20 Varia, offers variable pulse widths and delivers excellent results in highly demanding applications (e.g. corrosion-free marking). Not only outstanding marking results at high speeds in applications where a lot of material (metal, for example) is removed, but because of its variable pulse widths it can also handle delicate, high-precision work in high-speed applications. The powerful F 50 and F 100 lasers can be operated with pulse frequencies of up to 200 kHz. These lasers are particularly suited to high-speed marking and deep engraving, scribing and edge isolation as well as structuring and cutting applications. Features include:

- Completely air cooled

- Low overall operating costs

- Dual head configurations available to increase the size of the marking area

- Compact laser head

- Extremely flexible, with a variety of options, such as camera and positioning axes

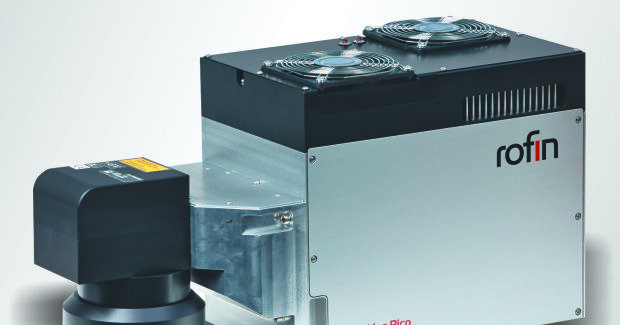

Also on display will be PowerLine Pico air-cooled short-pulse lasers that are dedicated to laser marking and engraving as well as thin film ablation and structuring. With their exceptionally high, variable pulse frequency, these short-pulse lasers ensure fast processing and maximum pulse-to-pulse overlap. This performance enhances the removal quality, reduces surface roughness, and allows for even greater precision for the selective removal of layers. With the thermal penetration depth during removal, sensitive processes such as marking certain metals and semiconductor materials can be significantly reduced with shorter pulses. PowerLine Pico lasers are ideally suited for challenging marking and micro applications.

Rofin offers short-pulse lasers in the femtosecond, picosecond and nanosecond range covering a wide range of customer-specific fields of application. They provide outstanding processing quality at high speed, and are the optimal solution for applications involving sensitive materials and miniaturized components. The PowerLine Pico can be easily integrated in customer specific systems because of its all-in-one design. Via TCP/IP, USB, or RSS 422 interfaces, the laser can be quickly and easily operated. ROFIN offers the PowerLine Pico in power ranges of 10 W and 50 W and wavelengths of 1064 nm and 532 nm. The PowerLine Pico is also available as a beam source without galvo. Features include:

- Low thermal penetration depth

- Outstanding process quality at high speed

- Configurable marking area size

- Compact dimensions, and easy integration

- Low operating costs

Rofin-Baasel Inc., 68 Barnum Road, Devens, MA 01434-3508, 978-635-9100, CTatosian@rofin-baasel.com, www.rofin.com.

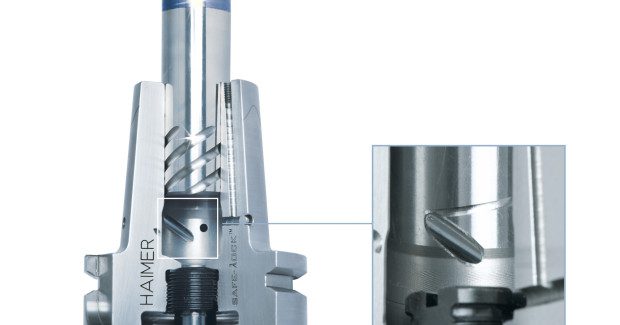

HIGH PERFORMING COOLANT THROUGH THREAD MILLS

In Booth 2702, Scientific Cutting Tools, Inc. (Simi Valley, CA) will show how their coolant through thread mills consistently outperform the competition in milling through a unique design that more efficiently utilizes coolant through technology, allowing the tool to retain its hardness and thereby extending its life. When cutting and drilling, the cutting tool material interface can reach temperatures in excess of 2,000 deg. When a tool gets this hot, chips can stick to it and damage the cutting edge unless they are cleared away quickly and effectively. Lowering the temperature at the cutting tool material interface by even a couple hundred degrees can extend a tool’s life to up to five times. For this reason, more machine tools are being designed with high pressure coolant through the spindle.

Unlike most coolant through tools which have one hole down the center of the tool and flutes out to the side, SCT coolant through thread mills have holes down the shank to each flute, allowing coolant to reach the cutting zone more efficiently without weakening the integrity of the tool. This allows SCT to make coolant through thread mills of any size, even micro-tools, that can be used for both blind and through holes.

Scientific Cutting Tools, Inc., 110 W Easy Street, Simi Valley, CA 93065, 805-584-9495, Fax: 805-584-9629, www.sct-usa.com.

ALUMINUM GANTRY CRANE

In Booth 1923, Spanco, Inc. (Morgantown, PA) will be exhibiting the Aluminum Gantry Crane and feature one system from each of three product lines: jib cranes, workstation bridge cranes, and gantry cranes. Each of these products has its own unique set of capabilities, which can also be fully customized to fit the needs of your specific application. The extremely portable and lightweight Aluminum Gantry Crane is one of the most flexible, ergonomic material handling systems available on the market today. Easy to move around a busy shop, or from one job site to another, they are remarkably easy to assemble and disassemble and are designed for exact precision — even in challenging locations.

https://youtu.be/5gfu-3fws1A

Once on location, Aluminum Gantry Cranes are quick to assemble, ready to lift, and able to position heavy or bulky objects in any environment. They are also corrosion resistant, making them ideal for refrigerated areas, clean rooms, and controlled environments where other material handling systems are either unsafe or can’t fit. With a variety of features and options, these ergonomic, flexible systems are height and span adjustable in order to meet the requirements for specific facilities, uneven floors, or tight locations with multiple obstructions. And, they use heavy-duty, four-position, swivel lock casters with polyurethane wheels that provide excellent floor protection when required.

Spanco, Inc., 604 Hemlock Road, Morgantown, PA 19543, 800-869-2080, www.spanco.com.

STORAGE AND WORKSPACE SOLUTIONS

On display in Booth 436 is Strong Hold Products (Louisville, KY) is a leading manufacturer of American-made industrial strength storage and workspace solutions that are constructed of heavy duty, durable 12 ga steel to withstand the toughest environments while keeping shop valuables organized and protected. Founded in 1993, long before 5S and lean manufacturing were popular trends in manufacturing, Strong Hold was making top grade industrial storage products. The company proudly manufactures over 10,000 products in Louisville with a wide variety of accessories and options, and will custom manufacture to your specifications, branding guidelines, colors, sizes and features. Visitors to the booth can check out the following products on hand:

The 4 Drawer Bin Cabinet (36-BBS-241-4DB) is the perfect 5S solution. Bin cabinets are typically used in environments where sorting of multiple parts is needed. This heavy duty cabinet can be ordered in sizes from 36 in to 48 in wide and 72 in tall, with multiple standard sizing options. Constructed of 12 ga steel, the bin cabinet with drawers is perfect for storing small parts and items while maintaining organization in your workspace. With one adjustable 14 ga shelve that can hold up to 1,900 lb and four drawers capable of storing 400 lb each, this cabinet stores large and small items. With 112 strong polypropylene bins in total, this model features 96 small bins on the doors and 16 larger bins inside the cabinet. All bins can be removed for easy access to items. With all-welded, wrap around body construction, these cabinets are built for rough and tough industrial use and provide the storage you need without taking up too much of your valuable shop floor. The 3-point locking device includes a hasp built into the handle for use with a padlock for added security. The 6 in tall, 7 ga legs are welded to the body to provide stability when lifting the cabinet with a forklift or pallet jack. It is recommended that bin cabinets be anchored to the floor when loaded.

The Top View Computer with Retractable Keyboard (26-CC-242-RK) is perfect for locking up computer accessories and protecting your equipment in environments where protection and security is needed. The retractable keyboard drawer unit measures 20 in wide x 22 in deep x 3 in high. The polycarbonate window allows a clear view of the monitor while maintaining protection of equipment. A seven outlet, 15 amp, 100 volt power strip and a fan for ventilation come installed. The top door is secured by a latch that can only be opened when the bottom doors are unlocked, providing extra security for the monitor. The center shelf is also perforated to keep equipment cool. The lower storage area comes complete with two full width adjustable shelves that can hold 1,900 lb of tools or other supplies. The 12 gauge steel cabinet includes a 3-point locking system, designed to keep items secure in the cabinet. The 6 in tall, 7 ga legs are welded to the body to provide stability when lifting the cabinet with a pallet jack or forklift.

The 5 Drawer Tool Carts (3-TC-240-4/5-1DB) are known to be the strongest in industry. Their rugged design makes them the ideal maintenance workstations on wheels. Constructed using 12 ga steel, featuring wrap around body design, and a standard 7 ga hearty steel work top, these beasts can handle almost whatever you can throw at them. The top of this model features side and back guards to prevent tools, parts, and projects from falling off the working area. The combination of 6 in high by 2 in wide ridged polyurethane swivel casters with brakes make maneuvering a loaded tool cart virtually effortless. Able to withstand up to a load of 2,000 lb. A handle is provided for steering. These tool carts can be locked up when not in use to keep your valuables safe. They are locked with a padlock using our standard 3-point locking system. These tool carts feature 4 half-width drawers that measure 13 in wide x 20 in deep x 6 in high and one full-width drawer that measures 29 in wide x 20 in deep x 6 in high. Each drawer has the capacity of 400 lb.

Strong Hold Products, 6333 Strawberry Lane, PO Box 9043, Louisville, KY 40214, 800-880-2625, Fax: 502-363-3827, info@strong-hold.com, www.strong-hold.com.

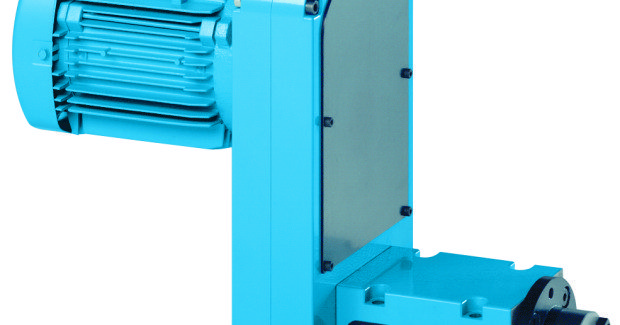

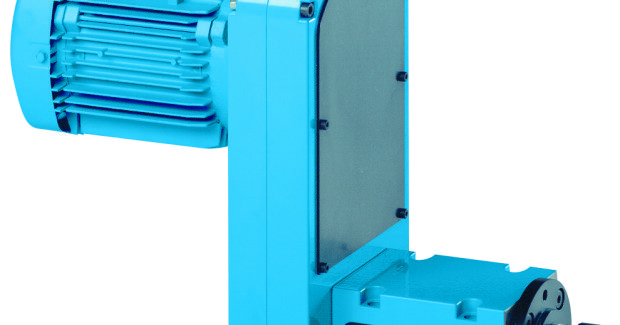

MACHINING UNIT FOR HIGHER SPINDLE SPEEDS

Chip producing machining operations with modern tools today demand progressively higher cutting speeds. In Booth 551, Suhner Industrial Products Corporation (Rome, GA) introduces a new and re-designed version of its BEX15 machining unit, capable to allow a spindle speed increase from 18,000 rpm to 23,000 rpm. Specifically for metals with high cutting speed rates or small diameter hole drilling applications, the machining unit type BEX15 has been proven in thousands of installations, providing new speed options reliably up to the maximum speed limit. With an increase of 25 percent up to a permissible maximum spindle speed of 23,000 rpm, operations requiring higher spindle speeds can be accomplished more easily. This improvement is the result of a complete redesign of drive and spindle bearing components. A new style timing belt drive multiplies the motor speed up to 13,050 rpm spindle speed. An AC-inverter drive is used to increase the spindle speed up to 23,000 rpm at 87 Hz.

The BEX15 machining unit can be applied in axial and radial orientation, directly mounted to a Suhner slide assembly type UA15-PH or UA15-CNC. In this combination, numerous machining operations like milling or demanding drilling cycles – including jump or peck feed – can be accomplished very easy. Four optional tool holder systems (Collet ER25, ISO30, HSK50 and Weldon), standard air purge connections for spindle and belt housing including a number of additional options (i.e., coolant through the spindle or automated tool change features) make this type BEX15 machining unit adaptable and an optimal choice for demanding and specific machining requirements.

Suhner Industrial Products Corporation, Highway 411 S at Suhner Drive, PO Box 1234, Rome, GA 30162-1234, 706-235-8046, Fax: 706-235-8045, automation.usa@suhner.com, www.suhner.com.

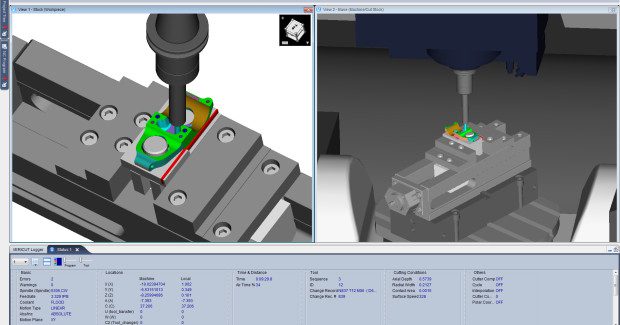

POWER-STROKED HORIZONTAL HONING

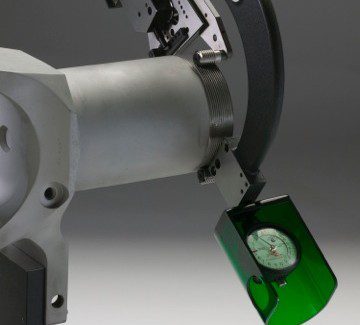

In Booth 1335, Sunnen Products Company (St. Louis, MO) displays the new SH-4000 power-stroked horizontal honing machine that introduces all-digital, servo-stroke honing for prototype to production volumes. The SH-4000 power-stroked honing machine merges a Siemens touchscreen PLC and digital-servo drives with a patent pending servo-hybrid tool feed system, extreme repeatability, and clear adjustable guard/light curtain for faster, operator-friendly setups. The SH-4000 is engineered as an easy-to-use flexible hone for medium to high production of parts with bore diameters from 1.5 mm to 101.6 mm (0.060 in to 4.0 in). It is capable of processing a wide variety of part sizes and configurations and cutting all kinds of materials quickly and efficiently. It features a 4.1 kW (5 hp) spindle drive and 1.1 kW (1.5 hp) stroker drive, with stroke travel up to 392 mm (15.43 in). Spindle speed is infinitely adjustable from 200 rpm to 3,000 rpm, with stroke rates of 10 spm to 550 spm.

With 45 percent fewer parts and greater reliability than predecessor models, the SH-4000 introduces patent-pending digital-servo tool feed and cutting pressure control for consistent, predictable performance throughout the pressure range. Cutting pressure can be adjusted in 4.5 N (1 ft-lb) increments to a new maximum of 2,224 N (500 ft-lb) – double the maximum of earlier models. The digital system provides superior feed control at low pressures for improved honing results with small-diameter parts. The higher cutting pressure, plus two-step honing capability, ensures short cycle times. Two-step honing allows high stock removal coupled with a precise finish step, all in one operation. In addition, the new tool feed system includes 20 mm (0.79 in) additional travel for increased diameter range when using high-production MMT tooling.

The new servo ballscrew stroker delivers extreme precision and repeatability for honing in blind bores, while a longer stroke length of 392 mm (15.43 in) allows the new machine to take on deeper bores. For fastest setup, the machine’s stroking system can be controlled with a joystick on the operator station. A new true-running spindle with direct collet connection allows quick setup or changeover with MMT tooling and the quick-setting runout-adjustable adapter allows installation of standard Sunnen tooling, such as K mandrels. Side access to the workzone enhances operator ergonomics during setup and facilitates integration with part-handling automation. Standard control features include saved setups, zero shutoff, stone wear compensation, feed speed regulation (stone saver), two-step feed, spindle reverse, speed changes while in cycle, inch/metric selectable units, system diagnostics, cycle dwell, in-process short stroking and 13 operator languages.