WESTEC 2015

The premier manufacturing event on the West Coast returns to the Los Angeles Convention Center on September 15-17. Take a look at some of the machinery, tooling, systems and accessories that will be exhibited that can help solve your most pressing problems, improve your productivity and increase your profits.

Posted: August 11, 2015

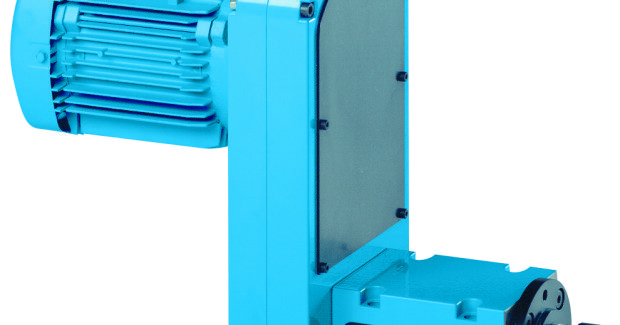

Sunnen will also demonstrate the popular SV-20 vertical honing system and HTE-1600W tube hone. The linear servo-stroking system on the SV-20 honing machine delivers the power to drive multi-stone diamond tools for OEM-quality bore geometry on automotive/truck blocks, cylinder liners and similar large parts. The SV-20 is a breakthrough design with class-leading price and features, such as computer-controlled spindle and stroke control, developed specifically for race shops, production rebuilders, and fleet maintenance facilities. The machine accepts blocks as large as the Cat 3126 in-line six and Ford 7.3 L V-8 (International 444) – even “mountain motors” with deck plates can be honed in one setup on the rollover fixture. Equipped with a variable-speed 15 rpm to 600 rpm, 5.5 hp (4.1 kW) spindle motor, the SV-20 is powerful enough to drive two-stage diamond honing tools through a 20 in stroke at up to 100 spm for short cycle times and minimal labor. The large multi-stone tools produce a rounder bore than ever before possible. The machine’s work envelope of 48 in x 30 in (1219 mm x 760 mm), front-loading design, and weight capacity up to 1,325 lb (600 kg), combine for versatility in processing a wide range of other large parts, such as compressor bodies and pumps.

The HTE honing system produces ideal bore geometry and surface finish, while eliminating problems from bad tool-to-part alignment and excessive feedrates that cause tool breaks and scrap parts. The tube hone’s one-piece base maintains excellent tool/part alignment, and a special feature of the feed system provides maximum protection against tool overloading. “The one-piece base not only improves the machine’s performance, it makes it more affordable,” said Dennis Westhoff, the business development manager for Sunnen. “The spindle power is also reduced on the low end, making the machine extremely sensitive to tool overloads in long, narrow bores.” Tool specific force limits and run settings are stored in the Windows-based touch-screen control. A unique feed system senses tight sections in the part and corrects them automatically.

Sunnen Products Company, 7910 Manchester Road, St. Louis, MO 63143, 314-781-2110 ext 2341, Fax: 314-951-2718, sales@sunnen.com, www.sunnen.com.

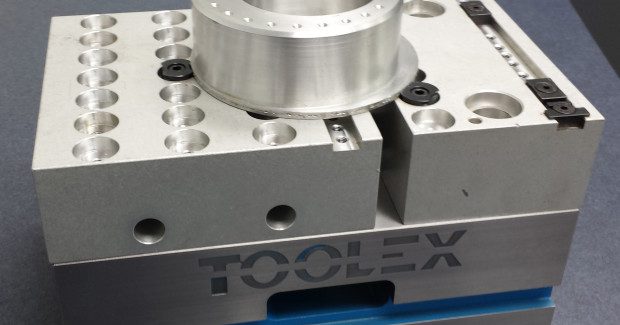

SELF CENTERING VISE FOR 5-AXIS MACHINING

In Booth 741, TE-CO, Inc. introduces a new Self Centering Vise for 5-axis applications. Its all steel construction provides the maximum rigidity and accuracies needed for 5-axis machining, with a newly designed screw assembly that is the best in the industry, offering maximum rigidity and accuracy. Talon Grip™ clamps are included to eliminate the need for workpiece preparation. Removable Jaw inserts allow the user to quickly and easily change out jaws for different workpieces.

TE-CO also introduces a new 6 in compact vise with machinable jaws that is ideal for 5-axis workholding or machines with a small work envelope. The machinable jaws allow more part contact to increase the clamping pressure and reduce the possibility of part movement and increasing accuracies. The vise is manufactured from 4140 steel for maximum rigidity in a small footprint that allows the vise to be used on most 5-axis machining centers. Due to its SnapLock jaw design, these jaws can be easily changed within seconds. They are available in aluminum and 4140 steel. TE-CO has the largest variety of jaw accessories available. This compact vise is also available in 4 in version.

TE-CO, Inc., 109 Quinter Farm Road, Union, OH 45322, 937-836-0961, Fax: 937-832-1274, dwion@te-co.com, www.te-co.com.

PARTNER PROGRAM FOR FANUC CNC MACHINE SERVICE

In Booth 507, Tennessee Industrial Electronics, LLC (TIE; LaVergne, TN) introduces its new partner program for Fanuc CNC machine service providers, resellers and integrated suppliers. The Uptime Partner Program is designed to offer various VIP rewards and benefits to our loyal customer base. The program features cash incentives and discounts, special expedited quote and order processing system, easy exchange on FANUC CNC new or refurbished parts, and other incentives. President Doug Peterson said, “We listened to our customers’ requests and are pleased to announce this new program to help them grow their business and earn extra cash. Another unique aspect of the program is that all approved members will receive free web listings on our corporate web site to help them get more referrals.” Interested companies are invited to stop by the booth to learn more.

Founded in 1992, Tennessee Industrial Electronics is a leading supplier of refurbished industrial electronic FANUC CNC component parts (controls, motors, drives, monitors, PCBs, robot parts) to end users, integrated suppliers, third party service providers and resellers. TIE delivers machine uptime with the world’s largest inventory of high quality, refurbished, certified and tested parts at up to 50 percent discount in return for a repairable exchange. In addition, TIE is committed to deliver high-touch, personal customer service and free tech support/troubleshooting services to all.

Tennessee Industrial Electronics, LLC, 1216 Heil Quaker Boulevard, LaVergne, TN 37086, 615-471-5070 x32, Shale@fanucworld.com, fanucworld.com.

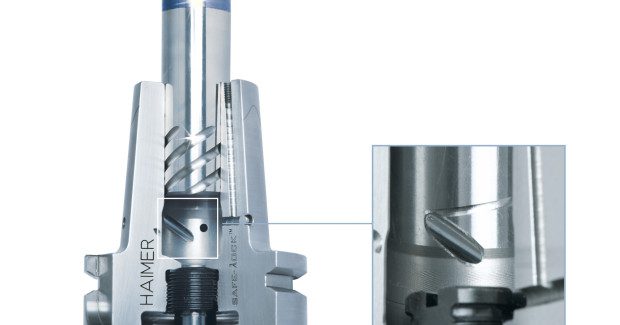

ELIMINATE TOOL PULLOUT

In Booth 2203, Haimer USA, LLC (Villa Park, IL), a worldwide leader in tool holder innovations, will be featuring the Safe-Lock™ system in both shrink fit and collet chuck style holders that uses a pin locking function in the ID of a tool holder to engage with a groove on the OD of a cutting tool. This new system completely eliminates tool pullout, an issue commonly experienced in rough milling applications. The added benefits of under 3 micron TIR and repeatable balance enable faster metal removal rates, better surface finishes and ensure the longevity of the machine tool spindle. Safe-Lock is the ideal solution versus older technologies like Weldon shank side lock holders that can be prone to runout and balance issues. The importance and impact of this new technology is made evident via 12 of the world’s largest leading round tool manufacturers that have all actively become licensed partners in Safe-Lock. Together, with these partners, Haimer aims to continue elevating the standard of quality in the metalworking industry.

(Right-click on video to translate to English)

Haimer USA, LLC, 134 Hill Street, Villa Park, IL 60181, 630-833-1500, www.haimer-usa.com.

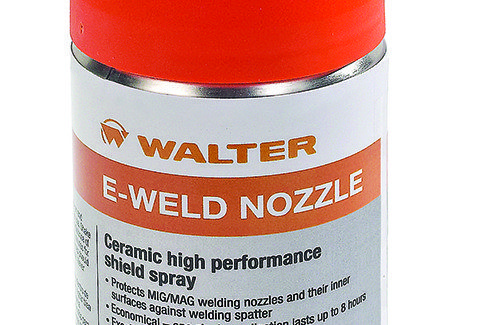

PROTECT WELDING NOZZLES FROM SPATTER ADHESION FOR EIGHT HOURS

In Booth 525, Walter Surface Technologies (Windsor, CT) displays the new E-Weld Nozzle ceramic-based anti-spatter solution with exclusive applicator that is designed to protect welding nozzles from spatter adhesion for up to eight hours. With its high concentration of active ingredients, this anti-spatter solution is made to outlast and outperform in the semi-automated and fully-automated MIG welding processes. The packaging features a unique applicator specially-designed to apply an even coating to the interior and exterior of the welding nozzle. In addition, the applicator provides significant economical benefit as it applies the exact amount of coating required to protect the nozzle for up to eight hours. Immediately after welding, spatter can easily be wiped off the welding nozzle using only a cloth and eliminating the usual downtime required to chip away accumulated spatter on nozzles when an anti-spatter solution is not used.

“By using E-Weld Nozzle with the easy applicator, shops can reduce operation cost as it eliminates the need for frequent nozzle replacements since the solution extends the life of the welding nozzle. What’s more, applying only a thin layer of this solution increases productivity and reduces downtime as it prevents obstructions from accumulating within the nozzle, allowing for a uniform and consistent flow of gas to form better quality welds,” explains Nathalie Vezina, a product manager at Walter Surface Technologies.

Also on display will be the new Surfox™ 304 MIG and TIG cleaning system, the only electrochemical system in the market to clean impurities on MIG and TIG welds. This revolutionary system now allows welders to safely and easily clean MIG and TIG welds without the need to use hazardous materials or the concern of altering the parent material’s surface. This is an industry game changer for welders as they now have a safer alternative to clean MIG and TIG welds, while also promoting the formation of a passivation layer on the surface.

https://youtu.be/Won5B7Z3XfQ?list=PLFk3JhCxdWmGbkJAUaULj6o_zDQIfP9yx

The Surfox 304 also features a unique patent-pending quick-change system that allows users to easily switch from one brush to another within seconds, without the need for added tools. In addition, it comes complete with an exclusive flow-through liquid system that delivers the exact amount of electrolytic solution to the brush, preventing the risk of burning and delivering a seamless and consistent cleaning every time. Three exclusive brush designs were created for the Surfox 304: a triangular sleeve for MIG welds, a cylindrical sleeve for spot welds and tight corners, and a micro-wand with a cylindrical sleeve for intricate areas. Current Surfox conductive pads can also be utilized with the new Surfox 304 system.

“Downtime and lowering cost of production have always been concerns in the industry. Weld cleaners today need a more efficient solution to cleaning MIG and TIG welds. By leveraging Surfox system welders, whether in large production facilities or in workshops, they can clean and promote passivation of stainless steel pieces in one simple step,” notes Jonathan Douville, a product manager at Walter Surface Technologies.

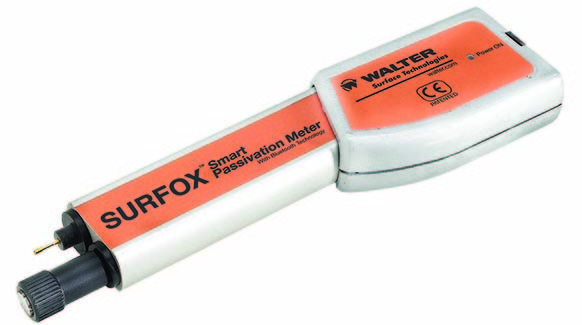

One particular component of the Surfox electrochemical cleaning system is the Surfox Smart Passivation Tester, a new “passivation” tool that analyzes passivation levels in stainless steel. The tool includes a cloud-based app that can be managed via smartphone to measure chemical levels and determine the degree of passivation in which the stainless steel item (e.g., in mixing tanks or drums) is currently contained. Passivation is the process by which chemical reactions cause stainless steel to reach a more protected state where they are less vulnerable to corrosion. It occurs when the chromium contained in stainless steel comes in contact with oxygen, forming a passive chromium oxide layer that protects a stainless steel surface. Once the passivation process is completed, materials are least affected by environmental factors.

The Surfox passivation app allows machinists to capture data, which is stored via the cloud, and utilize telemetry to analyze the changing chemical levels during this passivation process. Technicians can then map the oxidation process and track the progression of the passivation state in the stainless steel item and identify if the piece has been fully passivated to avoid rust and corrosion. “The concept of leveraging technology, cloud-based platforms and mobile apps to support production in the metal equipment industry is still emerging, yet it’s a way for machine shops and fabricators to differentiate themselves, offering more efficient and accurate assessments of how their metal equipment will endure over time,” adds Douville. “We’re looking to help our customers use these new technologies to become more competitive, especially smaller machine shops who are competing for business with larger companies that are in possession of greater resources. The more we can increase awareness of how technology can help deliver an edge to these shops, the sooner we can speed adoption of these enhanced processes in the market.”

The Surfox Smart Passivation Tester is part of a larger family of Surfox electrochemical cleaning products which deliver a safer (NSF-certified), cleaner, and more efficient method by which to clean stainless steel welds without altering the finish of metal surfaces. Stainless steel is pervasively used in facilities found in a wide range of industries, including the food and beverage, pharmaceutical, architecture and transportation industries.

Walter Surface Technologies, 810 Day Hill Road, Windsor, CT 06095, 860-298-1100, www.walter.com.

MEASURE SURFACE ROUGHNESS AND CONTOUR AT THE SAME TIME

In Booth 724, Carl Zeiss Industrial Metrology, LLC (Maple Grove, MN) is highlighting the NEX series of instruments with the Surfcom NEX 100 that uses a single hybrid detector to measure surface texture and contour at the same time. The Surfcom NEX 100 offers the highest accuracy in its class for roughness and contour measurements, and the analysis of both in one measuring run enhances measuring efficiency. Choose from multiple contour and roughness sensors to fit your application. The high-speed and low-vibration linear drive unit delivers long-term stable movement, for the highest measurement accuracy. This patented dual detector offers single data gathering at nano-level measurement resolution for roughness and contour profiling.

https://youtu.be/hcnsVFg9dj0

(Right-click on video to translate to English)

Surfcom NEX series has dedicated detectors with expanded contour range (60 mm) and highest fidelity (0.1 nm resolution min for surface roughness. New features include a 30 percent larger standard granite table over existing machines, expanded to 133 mm with T-slots for ease of part staging. Additional benefits of Surfcom NEX include an improved detector safety mechanism, quick change magnetic contour arms that do not require requalification, optional T-stylus probing for up/downward tracing, automatic stylus force (NEX 040) and a temperature correction function for assured accuracy within 20 deg C (±5 deg F).

Carl Zeiss Industrial Metrology, LLC, 6250 Sycamore Lane North, Maple Grove, MN 55369, 800-327-9735, www.zeiss.com/industrial-metrology.

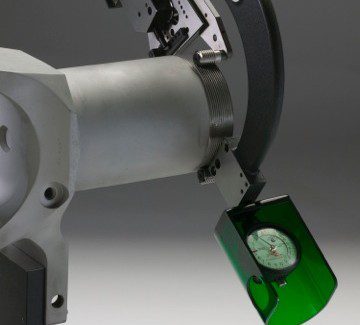

END MILL HOLDERS REDUCE TOTAL INDICATOR RUNOUT

In Booth 1040, Briney Tooling Systems (Bad Axe, MI) will feature their unique line of Tru Position™ End Mill Holders with dramatically reduced total indicator runout (TIR) of 0.0002 in. Tru Position End Mill Holders utilize a custom-engineered internal eccentric grinding technique that produces reduced runout capability. Advantages of this toolholder include less runout for a more even chip load with less chatter, fewer tool passes to mill slots because of improved on-center rotation, machining time savings and improved machining quality. Testing and production proven applications show these toolholders to have twice the cutting tool life of other conventional end mill holders, reducing cutting tool replacement costs by half. Briney will also have on display their complete line CNC, Shrink-Fit, HSK and collet style toolholders.

Briney Tooling Systems, 700 East Soper Road, Bad Axe, Michigan 48413, 989-269-9558, briney@geminigroup.net, www.brineytooling.com.

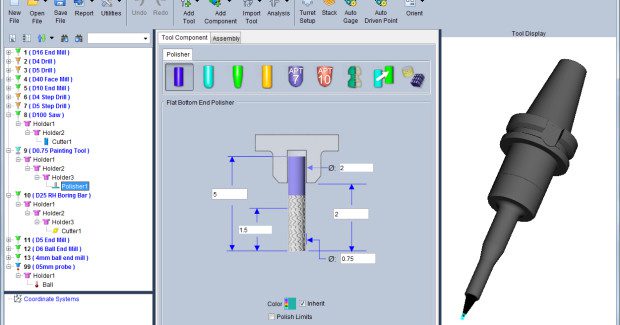

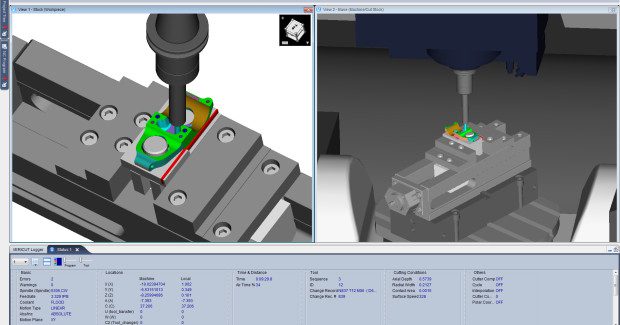

CNC MACHINE SIMULATION AND OPTIMIZATION SOFTWARE

In Booth 1927, CGTech (Irvine, CA) will demonstrate VERICUT 7.4, the new version of VERICUT® CNC machine simulation and optimization software that includes many enhancements to further simplify the process of simulating a CNC machine. Changes to how users interact with VERICUT further improve the software’s workflow and simplify day-to-day NC programming and simulation use. “This release increases the ability of manufacturing engineers to simulate the entire CNC machining process in order to produce better results and reduce the time spent in the programming and machining cycle,” said CGTech product marketing manager Bill Hasenjaeger. “This software is constantly refined to provide the flexibility and tools our customers require.”

VERICUT is CNC machine simulation, verification and optimization software that enables users to eliminate the process of manually proving out NC programs. It reduces scrap loss and rework. The program also optimizes NC programs in order to both save time and produce higher quality surface finish. VERICUT simulates all types of CNC machine tools, including those from leading manufacturers such as DMG MORI, Mazak, Makino, Matsuura, Hermle, DIXI, and Chiron. VERICUT runs standalone, but can also be integrated with leading CAM systems such as CATIA by Dassault Systems, NX by Siemens PLM Software, MasterCAM by CNC Software, PowerMill by Delcam, Edgecam by Vero, hyperMILL by Open Mind, and many others.

In Version 7.4, the first thing a user will notice is a Welcome Screen that automatically displays when launching a new session to provide access to commonly used first actions for a VERICUT session. The software user interface continues to get more customizable. VERICUT’s desktop is enhanced with a new docking method enabling the user to lay out their VERICUT desktop in the most efficient manner for the way that you work. The new docking method is very flexible and provides a high level of customization possibilities. Additionally, the Status window is completely redesigned for better viewing, customization and size. The Status window information is divided into Information Groups, each containing a specific list of information.

Tool Management has been simplified. Tool Manager’s desktop and user interface is re-designed to enable easier user interaction. A new Tool Bar located at the top of the Tool Manager window consists of a combination of icons and pull-down menus providing easy access to all features needed to create and maintain tool libraries, create/modify tool assemblies, import tool assemblies and create or import OptiPath records. Also, in the Tool List, tool components now have a Parent/Child hierarchy allowing for better tool assembly management and modification. All Tool Definition windows have been re-designed to make tool definition easier. Other new features in Version 7.4 include:

- New interfaces are available for integrating VERICUT with Creo Parametric 3.0, CAMWorks, and SolidWorks.

- OptiPath now automatically works through multiple setups.

- Selecting a tool from the new Reviewer Tool Menu automatically set the “Start” and “End” points of the simulation.

- Nearly 500 customer-driven enhancements and software change requests have been completed since version 7.3.

Version 7.4 also includes Force™, a new module of physics- and mathematics-based modeling software designed to optimize machining rates for machined parts within aerospace, automotive, industrial and other markets that utilize automated machining. Force determines the optimum speeds for a cutting process and makes the CNC machine cut in the most efficient, fast and reliable way, based on the type of material being cut. Force excels in difficult to machine materials, and especially complex multi-axis cuts such as 5-axis flank milling. Once the material is characterized, it can be applied to a broad range of cutters and machines in future NC machining operations. It’s easy to set-up and can also predict tool wear.

CGTech, 9000 Research Drive, Irvine, CA 92618, 949-753-1050, info@cgtech.com, cgtech.com.