Advanced Inspection Systems

A review of some of the new technologies and latest innovations in metrology now being used for testing and measurement.

Posted: September 7, 2015

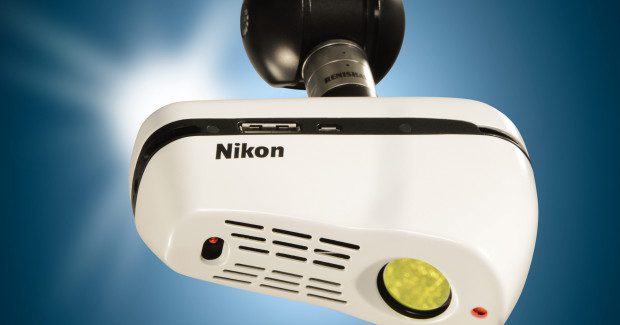

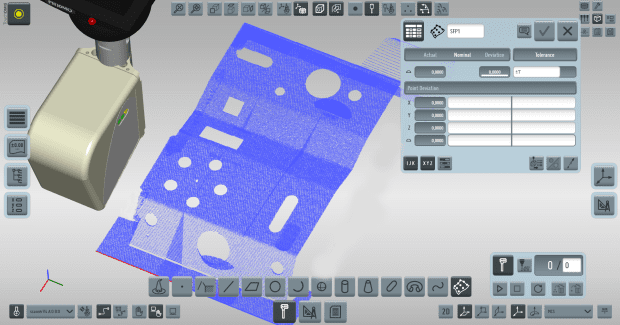

By utilizing laser scanning, manufacturers can gain full insight of the dimensional quality of their products without compromising on cycle times. As the entire part is checked to CAD model, any areas of concern are immediately highlighted using color mapping. Further investigation and analysis is possible using fly-outs, sections and a library of Geometric Dimensioning and Tolerancing (GD&T). As a picture is worth a thousand numbers, these easy-to-interpret graphical reports facilitate exchange of results with internal or external colleagues or suppliers. This ultimately leads to easier decision-making, faster corrective actions and shorter time-to-market. The InSight L100 scanner can be combined with tactile probes and change rack to create a versatile fully automated multi-sensor CMM. Depending on the application both technologies can be used independently or together within the same inspection program. The InSight L100 can also be retrofitted to a wide range of CMM brands.

Nikon Metrology, Inc., 12701 Grand River Road, Brighton, MI 48116, 810-494-5616, kate.vandermeulen@nikon.com, www.nikonmetrology.com.

ONE-SHOT MEASURING MICROSCOPE WITH IMAGE PROCESSING

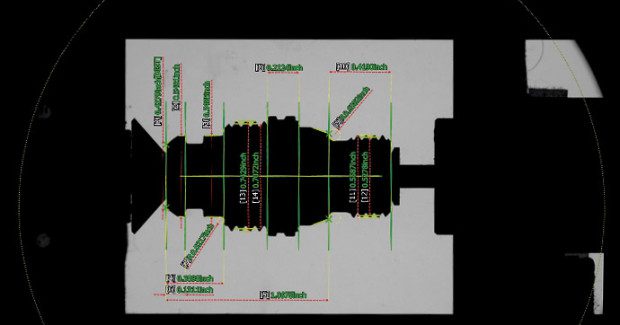

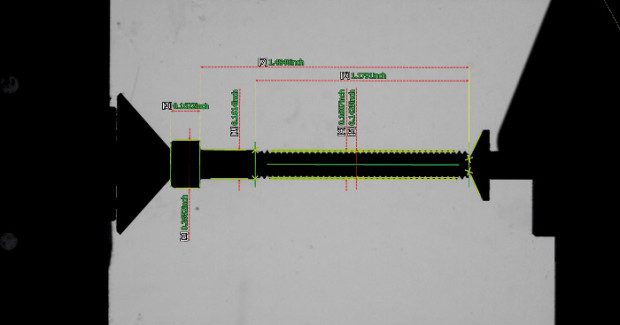

Mahr Federal Inc. (Providence, RI) has introduced a new video measuring microscope with image processing capability, the flagship product for its new line of optical measuring instruments. Designed for the measurement and/or dimensioning of geometric elements, the MarVision QM 300 incorporates an integrated CCD color camera with a 23 in touchscreen PC with keyboard and mouse, and easy-to-use Windows 8 based M3 software. Automatic edge detection allows even low contrast features to be measured, and a multi-touch function provides quick and continuous measurements using either touchscreen or the mouse. The QM 300 is a full-featured measuring station designed for fast, close to the grinding machine evaluation of cutting inserts or flat components such as punched and stamped parts.

“MarVision optical measuring instruments offer a quick and reliable solution to many different 2D measurement and inspection tasks,” said Rory Neill, the product manager for precision gages at Mahr Federal. “Applications range from cutting tools and precision products for manufacturing, plastics, and medical technology, to miniaturized electronic components. These extremely precise measuring instruments are designed to meet the highest quality and production requirements.” The MarVision QM 300 has a 40 mm (1.57 in) adjustable measuring table with a depth of focus of 10 mm (0.4 in). The 5 megapixel camera system provides for sharper imaging. Illumination is provided by a quadrant LED ring top light with four individually controlled segments, and table mounted Telecentric LED transmitted light for more focused measurement of rotationally symmetric parts.

The automated video edge detection and multi-touch functions make the MarVision QM 300 especially suitable for a wide range of punched and flexible parts, plastic components, and electronic circuit boards. Measurement and evaluation functions include: Point, such as the intersection of straight lines; Line, including line of best fit and/or centerline; automatic calculation of a Circle, including index and pitch circles; Distance between points or point and line; Angle taken from two lines; and Alignment of axis of the coordinate system on the test piece.

Other products in the MarVision line include a stereo-zoom microscope with or without digital camera, an optical measuring microscope with optional graphic LCD operating and display unit for evaluation of geometric elements and PC integration, and the MM 320 family that measures and dimensions geometric elements using integrated CCD color camera with zoom lens and 23 in touchscreen PC.

Mahr Federal Inc., 1144 Eddy Street, Providence RI 02905, 401-784-3100, Fax: 401-784-3246, information@mahr.com, www.mahr.com.

MEASURING MICROSCOPES, HEIGHT GAGES

Mitutoyo America Corporation (Aurora, IL) announces the availability of new generation D MF/MF-U® measuring microscopes that offer the long working-distance objectives and sub-micron accuracy glass scales of previous models, with the following enhancements added to the machines:

- Three-axis, motor-driven positioning with variable speed joystick control and collision prevention (Z-axis) to reduce operator fatigue and increase accuracy.

- The motorized X-, Y- and Z-axis motor functions that can be combined with a new Vision Unit to produce a new levels of automation in toolmaker microscopes.

- Laser Auto-Focus (LAF) models provide high accuracy and repeatability in two modes of operation: Just Focus (JF) mode for quick focusing and Tracking Focus (TF) for maintaining focus as the stage moves.

- Many optical options are available including magnification levels, BF/DF and LED illumination.

High repeatability and productivity make the new MF/MF-U microscope ideal for the measurement of cutting tools, molds and other machined components. Semi-conductor wafer holders specific to the generation D MF/MF-U measuring microscope are available. The new MF/MF-U Measuring Microscopes can also support output to measurement data applications such as the MeasurLink® proprietary statistical-processing and process-control program that performs statistical analysis and provides real-time display of measurement results for statistical process control (SPC) applications. The program can also be linked to a higher-level network environment for enterprise-wide functionality.

Mitutoyo’s next generation QM-Height digital height gage line offers a best-in-class accuracy of 4.5µm and significant improvements in design and capability to previous generation QM-Height gages. High accuracy / high resolution ABSOLUTE linear encoders for position detection ensure industry leading precision and dependability. A large stationary display panel with user friendly icon control keys and GO/NG LED indicator improve user operability. Enhanced measurement and memory capabilities in the QM-Height allow the capture of complex dimensional data. Measurement capabilities include height, as well as step, inside/outside widths, inside/outside diameters and circle pitch (height components), free-form surface maximum/minimum heights and displacement by scanning measurement. The QM-Height remembers the preceding measurement (height component) and can display the difference (pitch) between results below the measurement.

Two new models in the QM-Height line offer a pneumatic flotation system and an ergonomic positioning grip allowing the base of the gage to rise and smoothly move along surface plate for easy positioning. All new QM-Height models offer long battery life with (four) standard AA batteries lasting up to 300 hours (80 hours with regular use of pneumatic flotation function). QM-Height packages include an AC power adapter for uninterrupted use. All new models are fully compatible with existing Digimatic peripherals. Output options include Digimatic and USB. Wireless output is also possible using the U-WAVE wireless communication system.

Mitutoyo America Corporation, 965 Corporate Boulevard, Aurora, IL 60502, 630-820-9666, Fax: 630-820-2614, info@mitutoyo.com, www.mitutoyo.com.

HYBRID CMM WITH LASER LINE SCANNER & TOUCH PROBE

The Benchmark™ coordinate measuring machine from Coord3 Metrology (Plymouth, MI) offers shops a high-performance cost-competitive CMM with the added benefit of a small footprint. The unique ‘half-gantry’ advanced alloy design places its X- and Y-axis at the same level, providing increased rigidity and thermal stability. The unit offers an outstanding metrology platform for high accuracy small and medium part CMM inspection. The ergonomic open structure of Benchmark is ideal for the inspection of high-volume production parts or of single part inspection at the smaller manufacturing operations. Its compact size is ideal for production CMM or quality room applications and fits through a standard width door.