Advanced Inspection Systems

A review of some of the new technologies and latest innovations in metrology now being used for testing and measurement.

Posted: September 7, 2015

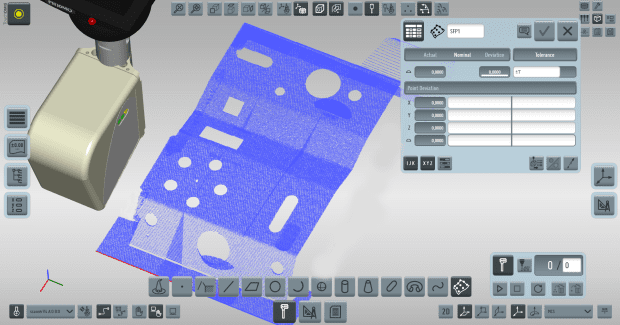

The full air-bearing Benchmark CMM, with accuracy of 2.5 microns and a measuring volume of 600 mm x 500 mm x 440 mm, comes equipped with both a Perceptron Laser Scanner and a Renishaw touch-probe. Following the acquisition of Coord3 by Perceptron, Inc. (Plymouth, MI), the company’s Laser Line Scanning Sensor has been seamlessly integrated into TouchDMIS™ software, allowing reverse engineering and dimensional inspection to be performed by the multi-sensor CMM. Benchmark is available in manual or CNC configurations. Manual units can be upgraded to full CNC in the field at a later date, offering a two-phase investment in CMM technology. The Hybrid Benchmark is the ideal job shop CMM.

Perceptron’s TouchDMIS, a ‘game-changing’ software for CMM usability, offers the world’s first all TOUCH CMM software with full CAD capability with newly-added point cloud handling capability. TouchDMIS requires just a few hours of training and takes the ‘expert’ out of CMM measuring and programming. “The introduction of this new product is a direct result of our recent acquisitions and is the first step in our plan to offer a full range of coordinate measuring machines with intuitive, easy-to-use software and best-in-industry scanning technology,” stated chief executive officer Jeff Armstrong of Perceptron, which supplies automated machine vision solutions, robot guidance, coordinate measuring machines, laser scanning, and advanced analysis software to manufacturers for dimensional gauging, dimensional inspection and 3D scanning to automotive, aerospace and other manufacturers. More than 900 systems, 12,000 Perceptron measuring sensors and over 3,000 Coord3 coordinate measuring machines are in active daily use worldwide.

Coord3 Metrology | Perceptron, Inc., 47827 Halyard Drive, Plymouth, MI 48170, 734-414-6100, Fax: 734-414-4700, emills@perceptron.com, www.perceptron.com.

ALL MEASUREMENTS ON ONE COORDINATE MEASURING MACHINE

The ROTOS roughness sensor enables the standard-compliant measurement of roughness and waviness on a single coordinate measuring machine from Carl Zeiss Industrial Metrology, LLC (Maple Grove, MN), meaning all features of a technical drawing can be fully captured with one CMM and displayed in one report. It is no longer necessary to transfer a workpiece to a surface measuring instrument. Various measuring positions can be reached without re-chucking and a fully automatic run is possible without the operator influencing the surface measurement. The roughness sensor enables a new, simpler workflow in quality assurance and is particularly suitable for the quality inspection of powertrain components.

“This new roughness sensor creates true added value for shops through the simplified workflow that provides more measuring certainty and enormous time savings,” explains says Dr. Dietrich Imkamp from Zeiss. It is intended for users that inspect size, position or form on a coordinate measuring machine and also need to measure roughness and waviness on the same workpiece. Instead of clamping the workpiece on a contact stylus instrument, ROTOS is used via the stylus changer interface on the probe of the CMM – under full CNC control. This takes just a few seconds compared to the previous method, which took several minutes. Because it is no longer necessary to transport and clamp the part, the susceptibility to errors throughout the process and operator influence are eliminated.”

The roughness sensor can be positioned flexibly to reach most surfaces on a part without re-chucking. Furthermore, the sensor features a rotating/tilting axis. The rotary axis can turn a full 360 deg. The sensor can be tilted perpendicularly via the tilt axis to provide a tilt range of 160 deg. ROTOS is connected to the measuring machine via the Vast line of active probes that dampen interferences from the machine and environment, and also determine the measuring position. Measurement data from the roughness sensor is transmitted via Bluetooth to the analysis computer. The data is then imported into Calypso software and can be exported with other measurement data in a common report.

In summary, the three key benefits of a workflow with this new roughness sensor are improved measuring productivity, reliable and fully automatic measuring runs, and the common report. They are based on the seamless interaction between the sensor, measuring machine and software. ROTOS is compatible with the Accura and Prismo CMMs and is available immediately through local representatives.

The O-INSPECT multi-sensor measuring machine from Zeiss is becoming more customizable and now provides even more flexibility for a wide range of applications. Thanks to the new additions to the O-INSPECT line, shops now have a greater selection of machine sizes, configurations and options. Anyone on the search for a contact-optical measuring machine will now be able to choose from several sizes, load capacities and contact probes. “All this with increased dynamics and the option of adding a chromatic focus sensor at any time. We are providing our customers with considerably more flexibility when they select the right system for their specific requirements,” noted Christoph Stark, a product manager at Zeiss.

O-INSPECT can be used for a wide range of activities, including the measurement of dental implants, tiny vehicle parts and sensitive smartphone components. For workpieces that are either too small or delicate, or when large quantities have to be measured, users can simply switch on the O-INSPECT camera sensor. For 3D characteristics, the benefits of the contact sensor come into play. The chromatic focus sensor closes the gap between the contact and camera sensors. Users of O-INSPECT are no longer limited to two system sizes. The smallest model measures just 300 mm x 200 mm x 200 mm, giving it a measuring range of 12 cubic decimeters. The next size up measures 500 mm x 400 mm x 300 mm or 60 cubic decimeters. An 863 model is offered for large or heavy workpieces or large pallets which hold many parts. It features a measuring range of 800 mm x 600 mm x 300 mm, or 144 cubic decimeters.

There is also greater flexibility with the contact sensor. The Vast XXT TL1 and Vast XXT TL3 scanning probes are now available. The TL1 features minimal measuring forces and is therefore ideal for scanning sensitive workpieces such as components for camera lenses and thin-walled, injection-molded plastic parts for smartphones. The TL3 can be used flexibly for larger workpieces.

Carl Zeiss Industrial Metrology, LLC, 6250 Sycamore Lane North, Maple Grove MN 55369, 763-744-2409, janelle.gregerson@zeiss.com, www.zeiss.com/metrology.