Automatic Bending Cells for Automotive Parts

Automatic bending cells simplify the manufacturing process, offer a high degree of occupational safety, withstand nonstop operation effortlessly, and increase productivity of hollow profiles for body and chassis construction, exhaust gas technology and other applications demanded by the automotive industry.

Posted: September 5, 2015

In order to be able to cope with the current and future demands of modern automobiles and commercial vehicles, the automotive supply industry depends on efficient processes and technical innovations. The rational production of hollow profiles for body and chassis construction, exhaust gas technology and many other fields of application benefit decisively from automatic bending cells that simplify the manufacturing process, offer a high degree of occupational safety, withstand nonstop operation effortlessly, and thus increase productivity.

Stricter threshold values for CO2 emissions, more efficiency in fuel consumption, higher demands on safety and comfort: these and many other aspects force automotive manufacturers and parts suppliers to build ever more components and to produce them smaller, lighter and more robust at the same time. The use of hollow profiles plays an important role in the fields of body and chassis construction, as well as in exhaust gas technology. In order to be able to ensure compact construction of future vehicle generations, pipes and tube profiles must provide ever more complex geometries and smaller bending radii. At the same time, new high-strength and especially light-weight materials, along with reduced wall thicknesses, create completely new demands that challenge the machining of hollow profiles.

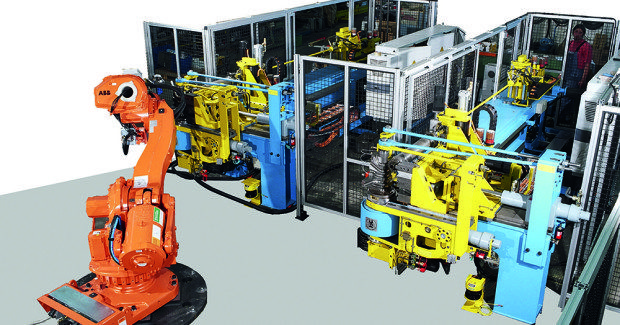

In order for automotive parts suppliers to ensure precise, speedy and economical mass production despite exacerbated conditions, many are relying on tailor-made tube bending cells more than ever. Automated cells permit a completely automatic production of tube and profiled semi-finished products, from tube separation and weld seam positioning via bending process to integrated quality control, reshaping or separation systems and unmanned further transport of the semi-finished products. Among other things, these cells offer special advantages in the rational series production of injection pipes, coolant and axle tubes, tie rods as well as several body, exhaust gas system and chassis components.

MANDREL BENDING

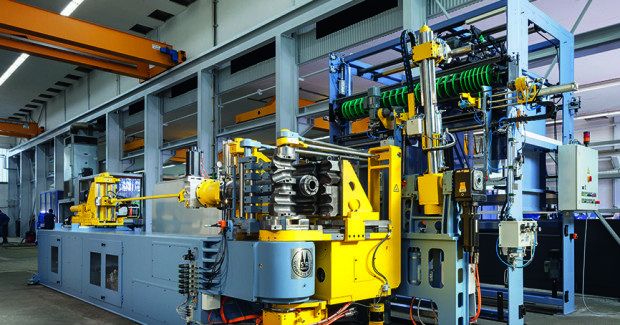

The centerpiece of an automatic bending cell is usually a mandrel bending machine. In contrast to warm bending, the cold bending process of this machine guarantees especially fast and energy efficient machining processes and hardly changes the microstructure of the material. Moreover, the use of a bending mandrel permits the reliable production of very small radii, even in case of thin-walled tubes. Tube bending machine manufacturer Schwarze-Robitec GmbH (Cologne, Germany) offers various mandrel bending machine series for the rational mass production of automotive parts. Without exception, these machines are freely programmable CNC-controlled plants that can be integrated into existing production processes without any problems.

The machines of the CNC MR series, for example, have been optimized for the efficient production of tubes with different radii or bend-in-bend geometries. Fitted with stacked bending tools, they ensure minimal set-up times. A flexible, modular, configurable accessory program is adapted to the specific project demands and needs of each plant in order to develop an ideal production solution. Furthermore, the high level of automation in the individualized manufacturing cells ensures that occupational safety is maximized.

AUTOMATIC BENDING LINES

The integration of the bending plant into the existing manufacturing chain is decisive for output and competitiveness of a shop, where storage, transport and manufacturing techniques must interlock like gear wheels. These machines are integrated into existing manufacturing cells, but they also supply completely harmonized, fully-automatic tube bending machines, depending on the demand and specification profile. If a high degree of automation is required, fully-automated machines will produce the best results, including optional integrated measuring systems that ensure fault-free bent tubes during production.

The freeform bending process used in these machines was developed over time by working with customers on different applications, including hollow profiles with radii of more than 6 x D that are fitted in automobiles and commercial vehicles to permit the efficient machining of large radii and complex geometries with different bending radii as well as high-strength materials. Despite the individual configurations of each individual bending machine and the automatic bending cell, they all provide competitive advantage by preparing a shop to meet the increasing demands for high speeds, short cycle times, maximum precision, ideal set-up times and long service life that are required by the automotive industry.

Founded in 1903, Schwarze-Robitec is among the international leading experts in the area of pipe bending machines and bending tools. The cold-bending machine specialist currently employs 120 staff in its headquarters in Cologne and is represented worldwide through long-standing partners. The company produced the world’s first CNC pipe bending machine in 1977 and has sold over 2,300 machines since then, many of which have been in unlimited use in production for over 30 years. The company also manufactures pipe perforating machines, measuring systems and special engineering solutions for the automotive industry, aerospace, energy sector, shipbuilding and other industries.