Automatic Generation of Weld Programs from CAD Models

The robot programmers at Groupe Gravel drastically reduce weld programming time and effort with Robotmaster software that generates robot control code directly from CAD/CAM.

Posted: September 25, 2015

Robotmaster is an off-line programming software from Robotmaster | Hypertherm Inc. (Saint-Laurent, QC) provides quick and easy programming tools for welding and cutting, helping robot programmers radically by saving time and money. Robot programmers can drastically reduce weld programming time and effort by adopting Robotmaster while maximizing a rapid return on their investment. This robotics programming software reduces programming time from hours to minutes by generating robot control code directly from CAD/CAM tools. As a result, shops can easily and efficiently program robots to produce higher quality products at lower cost, and achieve the speed and flexibility they need to challenge the competition. If shops are looking to generate more profit for their robot with a simplified, interactive and high-performance software, Robotmaster is the definitive choice.

The main features of Robotmaster include:

- Easy programming of simple to complex welds with full control of all welding parameters.

- Quick programming ideal for high-mix low-batch type manufacturing with an interactive and dynamic programming environment.

- Welding programs can be generated automatically from the CAD model and subsequently modified with minimal effort to adjust for optimal welds.

- Automatically manage work angle and gun angle for optimal welding.

- Gun orientations can be managed automatically to optimize the program for minimal wrist rotation and to maximize robot reach.

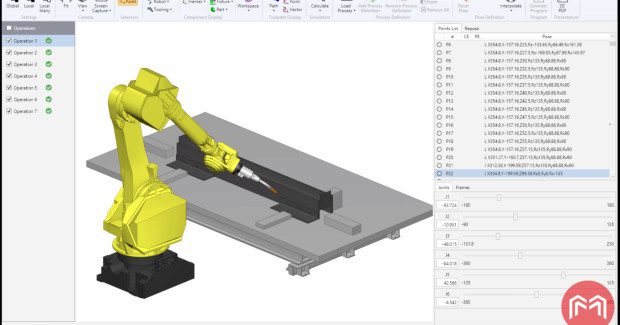

- Advanced programming tools for rails and rotary positioners to effortlessly exploit the flexibility (and added capacity/workspace) offered by external axes.

- Optimized welding paths that are free of robot singularity, collision, joint and reach limit issues.

- A unique and intuitive “click-and-drag” simulation environment for workspace analysis and fine-tuning of weld paths and transitions.

These features have been realized by Carrosserie Groupe Gravel (Montréal, QC), a family-owned machining and metalworking fabricator with 40 years of experience in offering one-stop service for custom production and repair services. In the last five years, they have been growing, delivering the vision of their president, Laurent Gravel, of an integrated turnkey service that offers parts optimization by in-house design engineering and reverse engineering, through production by welding, cutting, machining with full testing and quality control, to offsite installation and repair services. Their business has grown from a 1,000 sq ft shop to a 20,000 sq ft facility that employs 30 people. Their customers are most often in need of a single unit, a custom part for a single project, or the replacement, improvement, or repair of an existing part. A production run is most often one unit, rarely more than ten.

In 2013 Laurent Gravel decided that he needed to make his cutting and welding operation as precise and efficient as his CNC machining shop. He had experience working in CNC, but was looking to capitalize on capabilities related to cutting and welding for small batch production. Both precision and quality were crucial to the shop, and getting it right the first time with a minimum number of operation and handling was extremely important. That meant that speed, accuracy, and programming, as well as production, were factors which needed to be carefully taken into consideration. The shop gave themselves two years to install a robot work cell that could perform plasma cutting and welding on large work pieces. With no prior robot experience, Gravel was convinced the robot work cell would provide a faster response time with greater precision and quality in meeting production requirements.

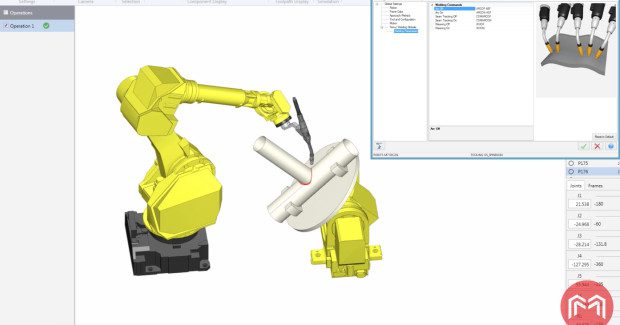

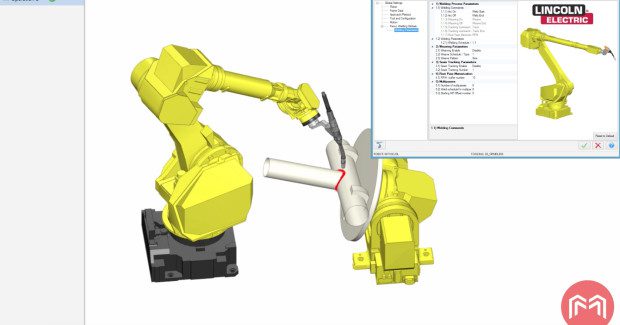

To accommodate arc welding on large work pieces, the shop selected a FANUC M-710 ic 20L long-arm robot with a 10 ft reach. The robot was integrated with an ESAB SP-150 PLASMARC plasma cutting system and a Lincoln Electric Power Wave 455M robotic arc welding package. Although the robot was equipped with a long reach, rotary positioners were required to enable cutting and welding for large tubular parts handled by the shop. Six months after the initial robot installation, a 2-axis positioner with a half-ton payload capacity was added.

Robotmaster’s personalized professional training program had Laurent and his team programming their robot with the Robotmaster cutting and welding package after only five days of training. The software tools enabled quick path creation from the CAD model and automatically set optimal tool orientations for cutting or welding. The interactive simulation environment permitted the shop’s plasma cutting experts to have the human touch, supplementing the automation with their technical knowhow and acquired expertise. Their natural and efficient manual intervention using easy graphical interfaces allowed for optimized control of the path, gun side tilt, push pull angles, and other path and point specific settings.

For Groupe Gravel, the automated creation of cutting and welding paths and control of gun orientations, improved part quality and drastically reduced programming time. The Robotmaster applications team, the robot integrator, Avant-Garde Technologies, Inc., and Groupe Gravel worked together to create process streams customized specifically for the programming of complex arc welding parameters. Screens were provided, for control of the weld start and end commands, for selection of the welding schedule number, and for controlling weaving and seam tracking. When the shop added a 2-axis rotary positioner, coordinating the rotary axis to the robot motion added a new level of complexity to programming. Robotmaster’s rotary axis management tools enabled the shop to program in either fixed indexing mode or as simultaneous 7-axis and 8-axis motion, and to integrate the robot and rotary axis control for optimized resolution of reach, singularity, collisions, and joint limitations.

Since adopting Robotmaster, Groupe Gravel has significantly increased programming capability threefold by rapidly reduced shop programming time from up to 6 hours down to only 90 minutes. The shop has also drastically improved the quality of their parts through enhanced precision and better control over cutting parameters, and also improved the safety and cleanliness of their workplace. Most importantly, Groupe Gravel has increased their profitability, as they were outsourcing 75 percent of their cutting production and are now down to only 10 percent.

To remain competitive, manufacturing environments are rapidly adopting robots to run their production lines. With a fully integrated programming software such as Robotmaster, manufacturers can easily incorporate the technology into a robotic application. Manufacturing giants or modest shops such as Gravel feel confident in considering and operating robots in their workflow. For the future, Robotmaster’s goal is to continue to build intuitive and easy-to-use robot programming software that is suitable for customers who have little or no expertise in robotics.

Carrosserie Groupe Gravel, 1830 Rue le Ber, Montréal, QC H3K 2A3, Canada, 514-932-9111.

Robotmaster | Hypertherm Inc., 5929 Rte Transcanadienne, Suite 330, Saint-Laurent, QC H4T 1Z6, Canada, 514-225-2206, www.robotmaster.com.