Innovative Pipe Bending Solutions

Tube Cold Bending Machines from Schwarze-Robitec are ideal tube and pipe fabrication in the automotive, shipbuilding and offshore industry, power plant construction and chemical industry, as well as special bending solutions for many other sectors.

Posted: September 15, 2015

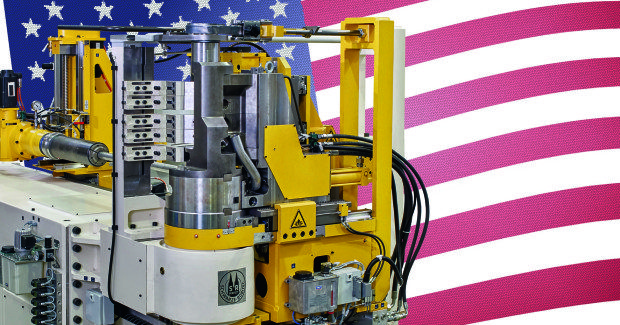

In Booth N-8103, the complete team of Schwarze-Robitec America Inc. (Big Rapids, MI), the new U.S. subsidiary of tube bending machine manufacturer Schwarze-Robitec GmbH (Köln, Germany), will showcase many new products and developments for resource-efficient production processes. As a leading manufacturer of Tube Cold Bending Machines, the long-standing German company that was founded in 1903 develops and manufactures tube bending machines for the automotive, shipbuilding and offshore industry, power plant construction and chemical industry, as well as special bending solutions for many other sectors.

To improve service for their rising number of customers that need application specific on-site advice about modifications, major overhauls of existing machines and optimization of bending processes, as well as shorter delivery times for spare parts across the U.S., Canada and Mexico, Chris Dorgan, the president of the North American subsidiary, along with his team and experts from Germany, will present the entire product line of tube cold bending machines ranging from 1/8 in to 16 in, including bending tool and application-specific equipment. Equipment includes state-of-the-art modular, configurable high-performance tube bending machines with newly developed CNC systems and innovative axillary programs for automotive applications that are faster and more cost effective.

(please right click for English translation)

A new addition to the axillary program is an innovative chopping tool that reduces tube waste by up to 90 percent and shortens production cycles considerably. Compared to existing processes that use an external shear to separate the component from the tensioning or support device after the bending process, this new tool requires only one work step to complete the bending and separation process. A Quick Tool Unlock central clamping device provides phenomenal time-saving potential by changing bending equipment fast, without using any additional tools. If different radii are required or elbow-to-elbow systems or tube systems (manifolds and exhaust pipes) must be produced, the multi-radius bending tools on these machines can be individually adjusted. Another highlight is a new CNC machine control system that intuitively prepares the subsequent work step as the current process is being performed, resulting in an ergonomic and efficient procedure.

Schwarze-Robitec America Inc., 18770 Windingbrook Road, Big Rapids, MI 49307, 231-598-9125, us-sales@schwarze-robitec.com, us-service@schwarze-robitec.com, www.schwarze-robitec.com.