Roll with the Punches

These punch and die sets can be great tools to help your shop reduce the cost of sheet metal fabrication.

Posted: September 5, 2015

ROLLER TOOLING INCREASES PRODUCTIVITY OF THICK TURRET PUNCH PRESSES

Mate Precision Tooling (Anoka, MN) introduces the new Roller Solutions™ tooling family that allows fabricators to quickly and cost effectively create rib, shear, offset and pincher features in sheet metal. Compared to traditional methods utilizing progressive forming tools, Roller Solutions dramatically increases productivity when creating detailed metal forms. This tooling is available in the following configurations:

- Rolling Rib tooling dramatically reduces the time taken to create stiffening ribs in products requiring additional strengthening. Ribs may be created in any contour, and started or ended anywhere on the sheet.

- Rolling Shear tooling is used for slitting and nibbling operations. It improves these functions by virtually eliminating burrs and reducing scrap. The rolling shear can be used to perform high-speed straight line and contour cutting.

- Rolling Offset tooling creates offsets and eliminates the need for press break secondary forming operations. This tooling can quickly create straight line and contoured offsets.

- Rolling Pincher tooling allows parts to be quickly and cleanly separated from surrounding metal without burrs. By utilizing precise scoring, this tooling creates parts that easily snap from the sheet with high quality edges.

Designed for thick-turret B-station applications, all four of these Roller Solutions tooling handle high-speed applications – equal to the programmed table travel speed. The tooling works well on a wide range of materials including stainless steel, mild steel and aluminum. The tooling is another great solution for reducing or eliminating expensive secondary operations.

Mate Precision Tooling, 1295 Lund Boulevard, Anoka, MN 55303, 800-328-4492, Fax: 800-541-0285, marketing@mate.com, www.mate.com.

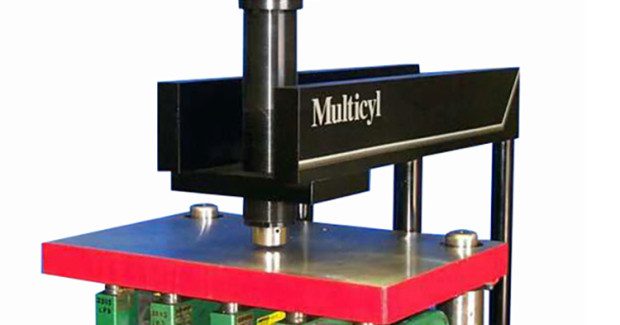

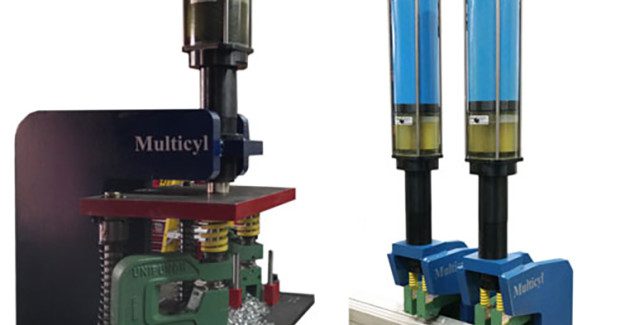

PUNCHING WITHOUT PRESSES

Combination gang punching that uses Unipunch tooling with cylinders from Multicyl® Inc. (Bolton, ON) offers shops a wide variety of standard and custom part producing options for jobs that require multiple punched holes. Simple to use and maintain, the Multicyl air over oil press system uses cylinder and cage designs that are compatible with the working shut heights of standard ‘A’ or ‘B’ series Unipunch C-frame units for a variety of metalworking applications. The most common is hole punching, but other applications include notching, shearing, tube piercing, assembly and metal joining. Individual cylinders suited to each of these applications can be purchased individually, but complete turn-key punching solutions are also offered that include air/oil cylinders capable of applying from 2.5 tons to 100 tons of force at cycle speeds up to 60 spm using regular shop air.

From single station punching to multiple turnkey punching systems, combination gang punching can increase productivity and lower costs in many ways:

- Low capital cost saves money up front.

- Dedicated stations free up more expensive capital equipment.

- Small batch production runs eliminate inventory and work in progress.

- Quick and easy production.

- Fast cycle times.

- Runs just on air.

- Low maintenance and easily obtainable replacement parts.

- Uses off the shelf products.

- Modular system which is easy to add to in the future.

- Compatible with other types of tooling in a work cell environment.

- Safe operating environment, often without additional safety features.

Start your Multicyl experience with a review of our applications or by checking out our products, or you can get right to work with our interactive SYSTEMATIC™ – Press Selection Tool approach to selecting your Multicyl system.

Multicyl Inc., 640 Hardwick Road, Unit 1, Bolton, ON, Canada, L7E 5R1, 905-951-0670, Fax: 905-951-0672, www.multicyl.com.