Tube Machining

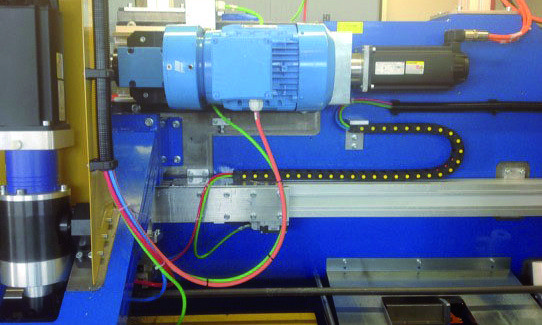

This transfer machine uses a CNC servo driven spindle and slide components to cut extremely difficult and challenging large and long OD threads on steel tubing parts used in the HVAC component industry.

Posted: September 5, 2015

Cutting, chamfering, face-off, turning and tapping operations that are used to prepare tubing and pipes, including thread milling or thread forming, generally require multiple manufacturing steps. Higher part quantities, usually combined with the need for different manufacturing steps, demand efficient production methods that help reduce cycle time and cost. To meet these demands, special purpose equipment such as rotary and linear transfer machines offer the best solutions to help shorten overall part cycle times. With an extensive background of experience in the construction of transfer machine operations, Suhner Industrial Products Corporation (Rome, GA) builds machinery that can optimize a manufacturing process by using standard or custom solutions for each machining application.

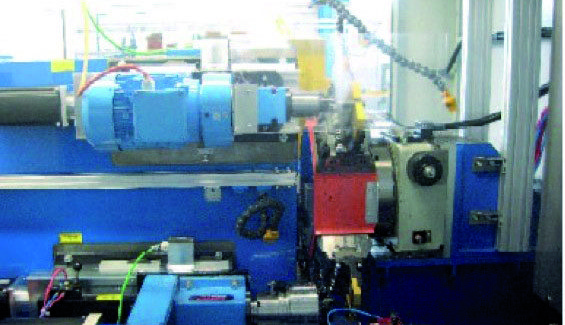

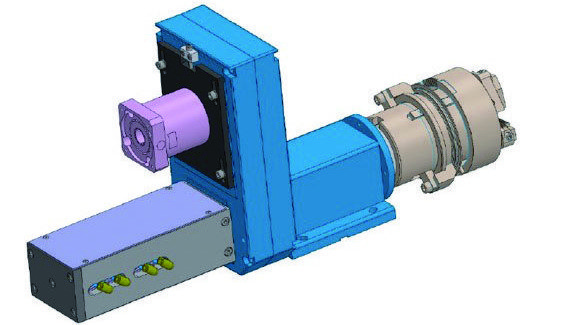

For example, one specific application for large and long OD threads on steel tubing parts used in the HVAC component industry involves seven part variations, each with a different thread size, pitch and length requirement. In cooperation with Wagner, a German manufacturer for OD thread rolling heads, Suhner developed a special process that performs threading operations in very short cycle times with a CNC servo driven spindle and slide components that also enables users to achieve very short changeover time.

https://youtu.be/OtKZpsIviJc

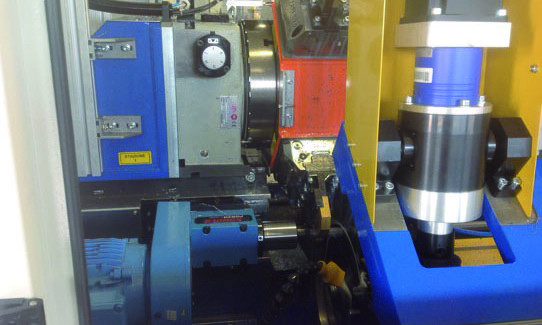

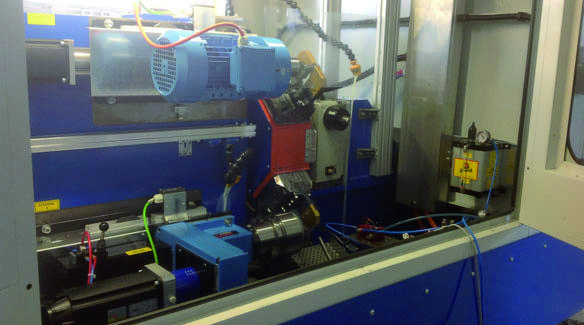

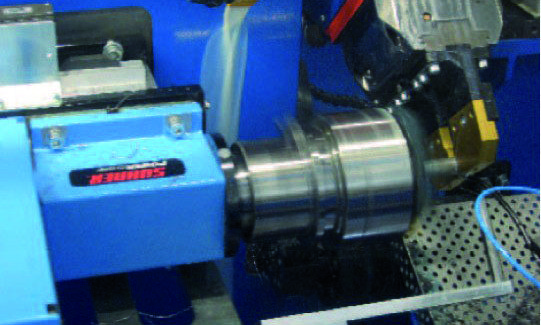

Operations performed include extremely difficult and challenging processes for shops that are trying to shorten cycle times, simply because the OD threading operation itself will dictate the overall machine cycle time. A pneumatic cylinder-activated system is used to open and close the thread rolling head, which is equipped with multiple thread cutting or forming inserts. The workpiece is fed from bar stock material. After a cut-to-length operation, the part is machined by three BEX15 machining units that use special Weldon tool holders and are equipped with a 1.5 kW motor and high precision angular contact spindle bearings to perform OD and ID and face turning operations.

The most interesting station on this machine is the one for an OD threading operation that is accomplished with a BEX35-ISO40 machining unit equipped with a Type Z27-2 thread rolling head. In this operation, the thread rolling head rotates while the workpiece remains stationary. The feed motion for this station is performed with a CNC slide unit. To synchronize the thread pitch, both the BEX35 spindle and CNC slide are driven with servo motors. Upon completion of the threading operation, the thread rolling head with its integrated inserts quickly opens to allow a fast return to the home position. Opening and closing action of the head is accomplished by an internal BEX35 drawbar controlled with a 3-position pneumatic cylinder that is designed to make an additional stroke of 10 mm to allow for head and insert adjustments or replacements, depending on thread size. Depending on length, a typical OD thread rolling cycle time ranges between 6 seconds to 10 seconds.

Suhner Industrial Products Corporation, Highway 411, South Suhner Drive, PO Box 1234, Rome, GA 30162-1234, 706-235-8046, Fax: 706 235 8045, automation.usa@suhner.com, www.suhner.com.