Tube & Pipe Fabrication Equipment

Here is some of the latest equipment now available to help shops cut their operating costs and monitor their tube and pipe fabrication process better than ever.

Posted: September 3, 2015

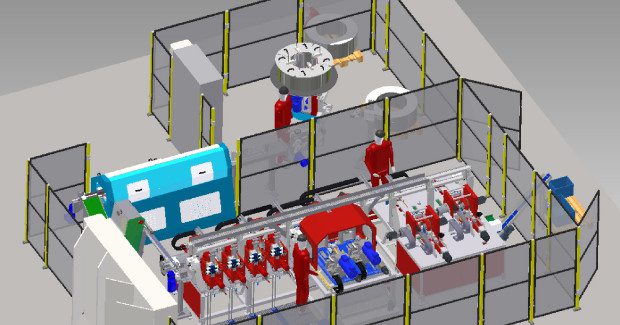

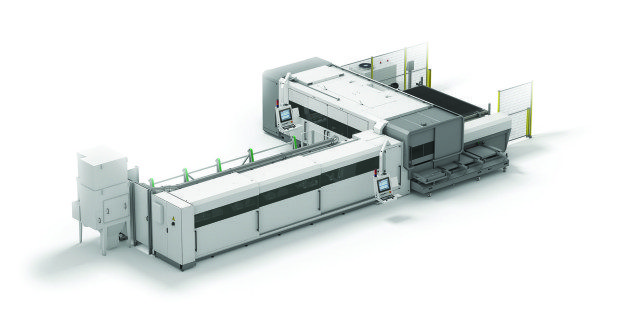

The unit features two separate 19 in touch screen consoles: one on the tube cutting side, one on the sheet side. For increased automatic production are optional one or two sheet storage towers on the loading and unloading side. The LC5 takes full advantage of the BLM Group Enterprise Software solution that incorporates full management of lasers, tube benders, end machining, and cold saws to manage production with real time production feedback. This optional package, incorporated with Artube, allows for seamless programming and production management.

BLM Group USA, 29380 Beck Road, Wixom, MI 48393, 248-560-0080, sales@blmgroupusa.com, www.blmgroup.com.

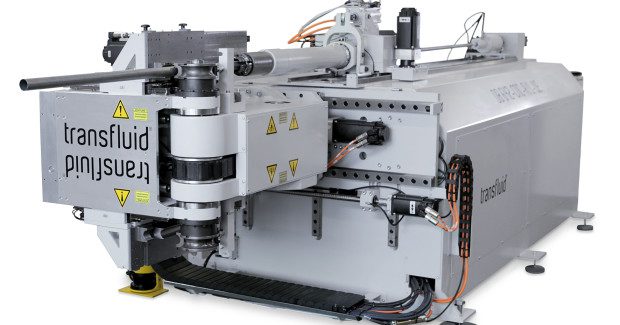

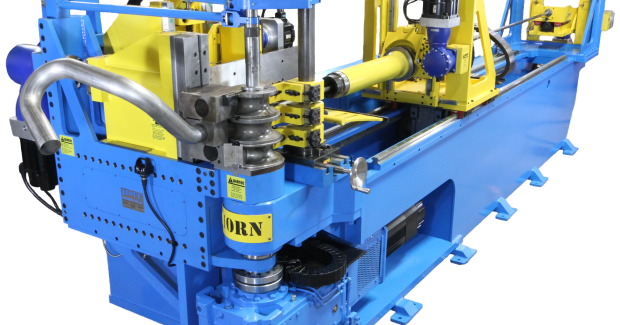

ALL ELECTRIC CNC TUBE BENDERS

An American manufacturer of world class tube bending equipment, Horn Machine Tools, Inc. (Madera, CA), has introduced a line of all electric CNC benders from 2 in to 10 in capacity that are based on the proven design of their hybrid benders, with the clamp and pressure die now equipped with large electric servo motors. The machines are 100 percent domestically designed and produced at the company’s Madera facility. These all electric benders have special features that can include “Quad Stack” design which allows the user to mount up to four sets of full size bend tools at once for the flexibility to switch between sizes rapidly or allow for greater capability to bend complex shapes. The machines can also be equipped with a shearing device and load/unload automation for continuous production.

These powerful machines are designed for 24/7 production and can bend very tight radius stainless steel on the rated diameter size. Draw bending in combination with push rolling capability are included as standard features. System reliability is enhanced by removing the hydraulics and implementing all digital servo systems with fewer components, less wiring and greater remote diagnostics capability. According to company president Kent Horn, “For some time now shops have been asking for a domestically produced all electric bender that is faster, easy to program and has overnight parts availability. Our line of all electric machines is the answer to all these requests and more. These machines bend tube very fast, but high production tube bending is not simply a matter of faster bending speed. It is also a combination of all the axes moving fast, in simultaneous motion, to reduce non-value added cycle time. Fast clamping, stack shifting and carriage positioning are going to improve production rates as well as bending speed.”

The machines are equipped with the BendPro CNC control which provides simple to use yet very powerful features for teach moves, cycle time optimization and remote troubleshooting capability. These all electric machines are the total package, powerful, fast, reliable, domestically produced with overnight parts availability and regional support for customers.

Horn Machine Tools, Inc., 40455 Brickyard Drive, Madera, CA 93636, 559-431-4131, Fax: 559-431-4431, www.hornmachinetools.com.

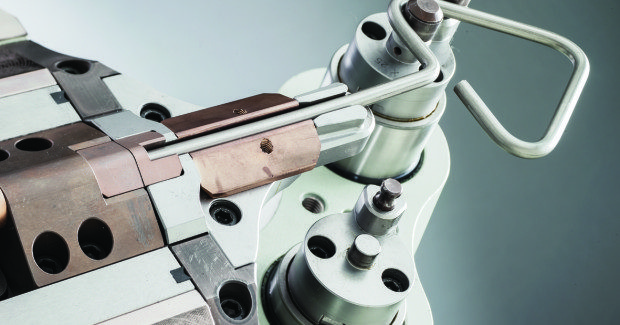

HYDRAULIC TUBE FORMING ON THE CONSTRUCTION SITE

Sometimes less is more. That’s also true for the size and weight of pre-assembly devices that are predominantly used at construction sites that need to have compact designs but nevertheless work precisely, fast and safe, just like the new VOSSForm 100 Compact forming machine from VOSS Fluid GmbH (Lüdenscheider, Germany). This mobile bench machine shapes a contour on hydraulic tubes that, in combination with a soft seal and function nuts, results in extremely leak-proof and process-reliable tube connections that are ideal for steel and stainless steel tubes from 6 mm to 42 mm OD.

Wherever safe and leak-free tube connections are important during repairs, maintenance and service, the VOSSForm 100 Compact mobile forming machine demonstrates its inherent advantages – including size and weight that is designed for shipping in a transporter, a mount for a forklift and additional lifting rings provide the unit with the mobility required at the construction site – that meet all the requirements to make secure tube couplings using a mobile forming machine that shapes a 24 deg tube contour at the end of a hydraulic tube which is supplemented with a soft seal and a function nut that is, in turn, equipped with a special clamping ring for an extremely high-quality and leak-proof connection that is exceptionally resistant to high bend change stresses.

Forming with the VOSSForm 100 Compact is extremely straightforward. The mechanic inserts the marked tool in the unit and pushes the tube end against the limit plate. During processing, the machine always displays the next operational step. The forming pressure setting is automatically controlled. The integrated tool is a negative mold of the contour shape that is desired to ensure the contour is always executed to perfection – a decisive competitive advantage of this forming machine. This rules out insertion mistakes and operator errors, effectively preventing scrap and leading to fast and precise results. The forming power of the machine is about 100 tons and is designed as a service unit for small lot production.

VOSS Fluid GmbH, Lüdenscheider Straße 52-54, 51688 Wipperfürth, +49 (0) 2267 63-0, Fax: +49 (0) 2267 63-9653, pr-marketing@voss-fluid.net, www.voss-fluid.net.

ACCURATE AND COST EFFECTIVE TUBE BENDING

Tube bending machine innovator Unison Ltd. (Scarborough, UK) has launched the EvBend 2000 rotary-draw tube bending machine, which it believes is a new category of tube bending machine designed to substantially lower the cost and skill level required to produce precision tubular parts in small volumes. Target sectors for this new machine, which can bend tube diameters of up to 2 in, include shipbuilding and equipment for oil, gas and other processing sectors.

The EvBend 2000 rotary-draw tube bending machine has a unique architecture that combines manual set-up with semi-manual operation of the bending arm, which has servomotor power assistance. This approach makes the machine intrinsically easy to understand and use, and inherently safe, requiring just a few minutes of training. Very precise tube bending results are assured by a unique CNC control system for the tube feed, carriage rotation, and bend axes. EvBend 2000 is a variant of the successful EvBend 1000 manual machine that can handle tubing diameters up to 7/8 in and is widely used in the aerospace sector. The new 2000 series machines can provide a bend torque of up to 4056 ft-lb to assist operation of the bend arm for handling larger tubing diameters up to 2 in, including tubing made from hard high-performance alloy materials.

The EvBend concept is lower cost compared with buying an automatic bending machine and the EvBend 2000 extends this formula to larger tubing sizes without sacrificing either safety or simplicity. Operator safety continues to be assured by the requirement for human force on the bend arm to engage the power assistance, plus a form of ‘dead man’s switch’ that provides a fail-safe mechanism to instantly remove the power assistance if the operator lets go or relaxes the grip on the handle. If a shop has demand for precision tubular parts in low volume, EvBend 2000 can provide a solution that has both a lower capital equipment cost and a much reduced need for operator skill.

These machines reduce the entry costs to precision rotary draw tube bending by using manual operations to feed and rotate tubing and move the bending arm, but with smart CNC-controlled braking on the carriage feed, rotation and bend arm axes to ensure part shapes are formed with the highest accuracy. Making prototypes or small quantities and reverse engineering of part shapes is very easy using this process as the bending program can be broken down into simple steps and reviewed. These machines can be configured with a right-hand or left-hand bending head. This orientation can also be changed by the user in around 15 minutes. There is almost no limit to the intricacy and multi-bend complexity of tubular shapes that can be formed, thanks to an ultra-compact bending head, and the versatility that manual/semi-manual operation brings to the manipulation process. However, sheer ease of use of operation is usually this machine’s strongest selling point.

Operators typically grasp how the machine works within minutes. Users can create bending programs in two ways. First, by entering the standard tube bending information (XYZ/YBC/LRA values, or the distance tube is fed out, rotated, and the angle of bend) into dialog screens on the Windows operator interface; this data can also be transferred from a coordinate measuring machine. Alternatively, users can program the machine using a teaching mode, which is particularly powerful: it is so simple to use that a part can be reverse-engineered by bending and comparing a tube against an existing part – with the user capturing the underlying material feed, rotation, and angle of bend information as the desired points are reached.