Wire EDM Maintenance

Many items must be properly addressed to keep a wire EDM machine in top operating order for the best productivity and reliability. Reviewing these on a regular basis ensures that the machine it being properly maintained as a proactive preventive measure.

Posted: September 3, 2015

On a wire EDM machine, both the mechanical components that drive and apply tension to the machining wire and the electrical components that deliver precise power to this wire during machining must work together for optimum results. On any type of machine tool, components wear over time and require proper intervals of maintenance to stay productive. But on a wire EDM machine, maintenance is especially critical for reliable operations. If maintenance is neglected, it will result in a loss of valuable machining time and in operational issues including wire breaks, slow cutting speeds, poor accuracy results and unreliable automatic wire threading.

Any one of these can decrease efficiency on its own, but when the issues are combined, they rob a shop of productive unattended machining time. This concept of regular EDM maintenance is more intensive than other machines in the shop floor environment and should be performed proactively at set intervals.

WIRE EDM MAINTENANCE ITEMS

While the type and interval of maintenance varies by the make and model of a machine, there are many common wire EDM maintenance items that need to be performed. Exchanging the wire spool seems intuitive because it is required for normal WEDM operation. The spool supplies and renews the cutting tool that performs the work. The wire collection bin that holds the used wire must be emptied at regular intervals. Since coated wires are dirtier, they require the machine to be maintained more frequently.

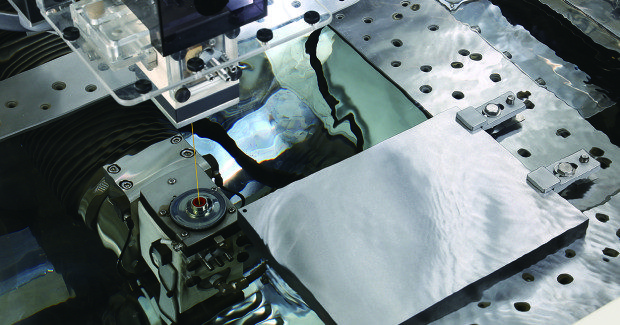

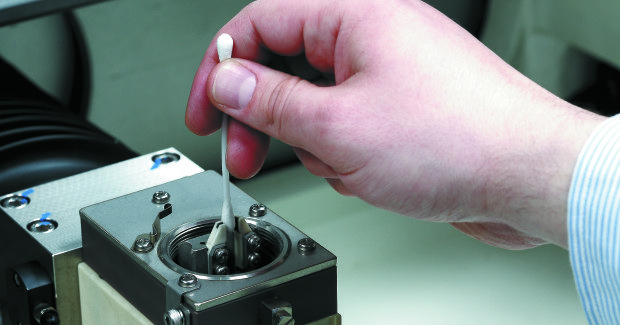

True to its name, the automatic wire threading unit performs the automatic threading of the wire. This unit is the single-most-important automated feature on the machine and allows for reliable unattended machining. Maintenance of this unit consists of simple cleaning. There are two electrical contacts that deliver the machining power to the wire. The contacts will wear over time and require indexing and eventual replacement because, as the contacts are depleted, the machining speed is significantly decreased. Indexing the energizer plates involves moving the contact by a specific measured amount, and it is performed between 60 hours to 80 hours. The wire guides provide the precision alignment of the wire within the machine and can become dirty and build up debris to the point of clogging. Round wire guides are the most common, and should be removed for cleaning. It’s important not to forget to perform vertical alignment calibration after cleaning.

There are several rollers that support and drive the wire that become dirty. If wire drive rollers are not properly cleaned, the wire may slip across the rollers, affecting part accuracy and surface finish and increasing the probability of wire breaks. The three most important rollers making up the wire transport system are the clutch roller, which controls tension; the 90 pivot roller, which is located in the lower head; and the pinch rollers, which pull the used wire in the back of the machine and into the collection bin.

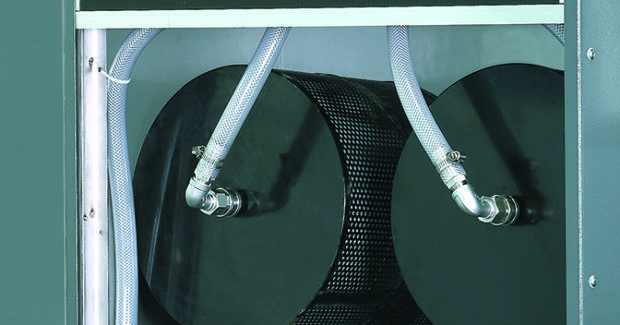

The main water filters purify the water and remove the debris that is created during machining to maintain stable EDM production. There are four different filter types, which are determined by the direction of water flow. Inside-out filters are larger in size and sit inside the machine. These are usually quicker with less mess, but require the water to be evacuated from the machine first. Outside-in filtration can be a bit messier and is located in a pressurized canister on the machine. Paper media provides adequate performance with lower cost, while synthetic media provides longer filter life and enhanced filter performance at a higher cost. Deionization resin (di-resin) is necessary to control the conductivity of the water for stable EDM machining; if water level becomes too high, the EDM machining becomes unstable as the dielectric is too conductive and can’t act as an insulator. The water reservoir must also be maintained.

Finally, general cleaning is probably the most overlooked item of wire EDM maintenance. This entails the simple washing of the work tank area, work table and seal plate. It’s important to remember that EDM debris consists of very fine, abrasive particles that build up and create a hard scale over time. Specially designed EDM acid cleaners are used for general cleaning. Be sure to use these proper/approved chemical cleaners, and don’t spray them directly into the machine.

MAINTENANCE INTERVALS AND COSTS

Performing these general maintenance items will extend the life of the consumable components. While timing will vary between machines, wire EDM maintenance is typically performed using short-term (weekly) and long-term (monthly) strategies. Some of the short-term maintenance items include the wire spool, energizer plates, automotive wire threading unit and general cleaning. Long-term items include wire guide cleaning, wire drive rollers, filters, di-resin and general cleaning.

Machine maintenance costs typically include the consumable parts costs and the direct labor, but actual total cost of maintenance should include the lost billable machine hours that occur while the machine is not in operation. To save on these maintenance costs, it’s important to choose a high-performance machine that eliminates as much maintenance and wear to parts as possible. These have a few time-saving measures such as:

- Simplified wire threading unit with less components for simplicity and reliable performance

- Fast and easy indexing of the energizer plates through a tool-less system with a one-click index

- Development of long-life energizer plate to dramatically improve the service life of the contacts and also lower consumables costs

- Minimized wire guide maintenance due to the wire guide design

- Filter air purge function to drain excess water from the filters to reduce filter weight and prevent spills

- Intelligent on-machine maintenance tracking to track the health of all the items on the machine

KEEP THE PARTS FLOWING

As mentioned earlier, many items must be properly addressed to keep a wire EDM machine in top operating order. Reviewing these on a regular basis ensures that all proper maintenance procedures are being performed on the machine. For best productivity and reliability, it is critical that machine maintenance disciplines are handled as a proactive preventive measure.