Get More Out of Ironworking Operations

Edwards Manufacturing will display 12 Ironworkers and 5 Hydraulic Accessory Tools as part of the most extensive line of Ironworkers and Hydraulic Accessory Tools for the metal fabrication industry.

Posted: October 28, 2015

In Booth S-3376, Edwards Manufacturing Company (Albert Lea, MN) will display 12 Ironworkers and 5 Hydraulic Accessory Tools as part of the most extensive line of Ironworkers and Hydraulic Accessory Tools for the metal fabrication industry. Attendees can meet the talented and friendly team of this 140-year-old manufacturing company and learn why ‘Made in America’ matters. In 2009, the company started asking for more capabilities of Ironworkers when they created the patent-pending Hydraulic Accessory Pack, an option that powers supplemental hydraulic tooling. First, they made a Pipe/Tube Bender and fabrication shops went wild. Next, they created a stout 40 Ton Shop Press and its little brother the 20 Ton, a powerful and compact unit that fits nicely on a shop bench. After listening to their customers, they are now expanding their Hydraulic Accessory Tool line with two exciting new products: a versatile, innovative and affordable Horizontal Press and Radius Roller that provides all of the utility a shop can imagine.

With 20 tons of force, the 20 Ton Horizontal Press accepts a great variety of tooling to form, brake, and straighten mild steel. This compact powerhouse quickly connects to an Edwards Ironworker with a Hydraulic Accessory Pack or Edwards Porta-Power to greatly expand its fabrication capabilities. Designed for maximum tooling flexibility, the four pin locations are locked with a simple crank for inboard tool squaring. The included digital encoder reads positive stop for accurate repeatability within 0.01 in. The potential of this tool is only limited by your imagination.

General specifications of the 20 Ton Horizontal Press include:

- Rating: 20 Tons

- Cylinder: 2.25 in

- Ram Stroke: 10 in

- Work Height: 38 in to 40 in

- Table Dimensions: 24 in x 42 in

- Weight: 1350 lb

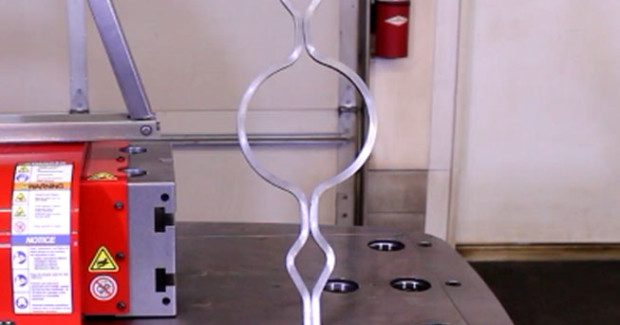

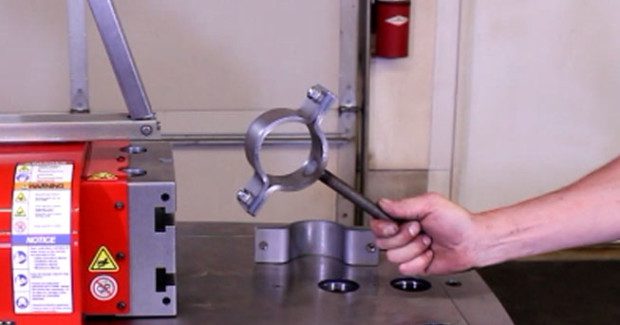

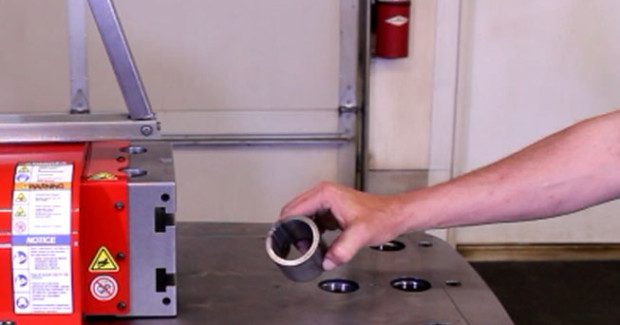

The Pipe, Tube and Section Radius Roller is another essential quick-connect hydraulic tool. Plug it into an Edwards Ironworker with the Hydraulic Accessory Pack or power it separately with an Edwards Porta-Power to greatly expand its fabrication capabilities. Designed for medium to heavy material, the Radius Roller powers through a job quickly and accurately. The variable speed hydraulic drive allows a shop to dial in the appropriate speed for various materials. Quickly change the orientation from vertical for smaller projects to horizontal for those larger, heavier jobs.

General specifications of the Pipe, Tube and Section Radius Roller include:

- Height: 43 in

- Width: 45 in

- Depth: 49 in

- Shaft Diameter 2.0 in

- Shaft Center Distance 14.12 in

Material capacities of the Pipe, Tube and Section Radius Roller include:

- Round Pipe 2 in Schedule 40

- Round Tube 2-1/2 in (.095 in)

- Square Tube 2 in (.120 in)

- Solid Round 1.375 in

- Flat Bar – Easy Way 4 in (.75 in)

- Flat Bar – Hard Way 2.25 in (.375 in)

- Angle Iron 2 in (.250 in)

Edwards Manufacturing Company, 1107 Sykes Street, Albert Lea, MN 56007, 507-373-8206, Fax: 507-373-9433, www.edwardsironworkers.com.