Laser Marker Workstation for Lean Operations

Ideal for low volume production and R&D, Amada Miyachi showcases advanced laser marking technology in the compact and highly configurable LMWS laser marker workstation.

Posted: October 28, 2015

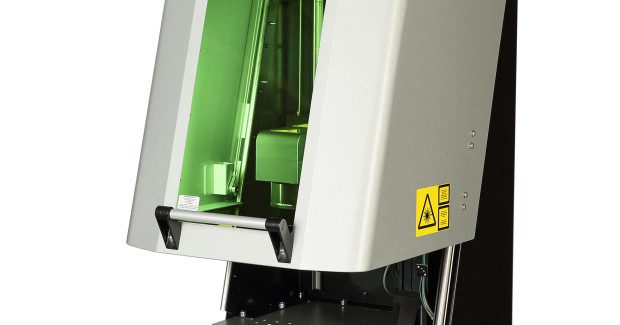

In Booth S-901, Amada Miyachi America, Inc. (Monrovia, CA), a leading manufacturer of welding, marking, cutting and micro machining equipment and systems, will be showcasing their latest laser marking technology with the LMWS laser marker workstation, a compact and highly configurable workstation designed for lean manufacturing and ideal for low volume production and R&D environments. The new compact CE compliant and CDRH Class 1 LMWS laser marking station is designed for bench top operation and requires minimal workspace. A great choice for marking on metals, plastics and ceramics, the LMWS can also cut, drill, ablate and weld thin materials. With its compact footprint, available custom fixtures, and optional motorized rotary axis for marking cylindrical parts, the LMWS workstation is an ideal solution for manual batch part making.

A major facelift to the existing line of marker workstations, the LMWS features a fresh industrial design, and improved functionality. With manually operated vertical doors, the LMWS provides a full, 180-degree of workspace access to parts and tooling and a large viewing window that facilitates visual process monitoring. Visitors to the booth can see a demonstration of the LMWS, which is integrated with Amada Miyachi’s industrially proven LMF Fiber Laser Markers (10W to 50W). The unit includes a threaded, metric base plate for part positioning, and an automated z-axis for easy laser focus adjustment. A rotary axis can be added as an option. The LMWS features F-Theta 100 mm, 160 mm and 254 mm lens options for marking various parts and sizes. The LWMS supports a wide variety of mark types, including line-art and shaded graphics, TrueType™ fonts, Data Matrix and QR codes, and a variety of other barcode systems.

Amada Miyachi America is an ISO9001 certified company and leading manufacturer of equipment and systems for resistance welding, laser welding, laser marking, laser cutting, and hot bar reflow soldering and bonding. The company provides products to a wide range of markets, including the medical device, battery, electric vehicle, and solar industries, as well as the global electronics, automotive, and general industrial markets.

Amada Miyachi America, Inc., 1820 South Myrtle Avenue, Monrovia, CA 91016, 626-303-5676, info@amadamiyachi.com, www.amadamiyachi.com.