Sight for Sore Eyes

Clearly, the right auto-darkening helmet boosts productivity and quality. Here’s how optical clarity defines helmet performance by providing users with vital eye protection and the ability to fully see the work . . . and that’s when work is done best.

Posted: October 3, 2015

Welding operators are often tasked with joining any number of materials, often under difficult conditions – out-of-position, in extreme heat or humidity, on thick or thin steel, stainless steel aluminum or other alloys. Beyond safety, selection of an auto-darkening welding helmet demands attention to user vision. Optical clarity – how well a user can see out of the helmet – directly correlates to welding quality and productivity, all the while protecting the wearer’s eyes.

Welding can require that the helmet be worn for an extended period of time. Welding demands skill, and skills suffer when sight is compromised. Without clear vision, such nuances as ever-changing arc behavior and weld puddles may remain undetected, ultimately affecting accuracy and quality and wasting time. Variations in visual quality through a helmet’s auto-darkening cartridge, or a helmet that remains too dark, can cause discomfort, vision problems and irregular welds. Wouldn’t you want the same viewing quality from your welding helmet’s LCD based cartridge as you expect from your high-definition television?

MEASURING OPTICAL CLARITY

Hence the need to examine optical clarity. Can clarity be measured? Yes, it can. And it has. The United States has yet to adopt formal requirements for welding helmet visual issues, but some manufacturers have looked to guidance via the third-party European Standards that include a standard which governs auto-darkening welding helmet cartridges. Prefixed by EN (European Norm), this standard is known as EN379 and incorporates important ratings for optical clarity.

Optical-clarity ratings are determined by tests measuring light transmission across the welding cartridge, as well as scattered light from the cartridge’s layers. Rating tests are conducted in four classes of optical clarity:

- Optical — Qualifies image distortion when viewed through a welding helmet lens. Is the view similar to looking through rippled water, or is it clear and crisp?

- Light diffusion — Measures manufacturing impurities in the cartridge glass. Is the glass clear, defect-free and uniform?

- Variations in luminous transmittance — Examines light and dark areas within the lens, focusing on the lens’ adjustable shade function and consistency of this shade across different points of the lens surface. The lens should exhibit no random areas that are either overly bright or dark.

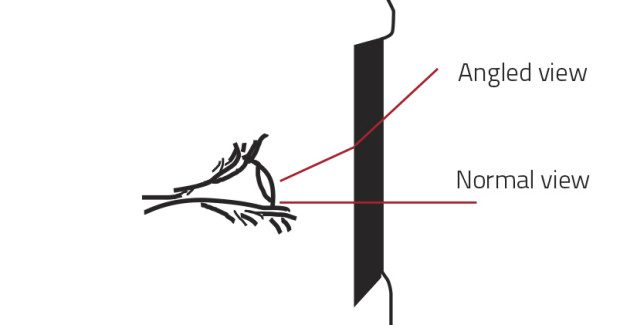

- Angle dependence on luminous transmittance — Tests for clear, angled views, without stretching, dark areas, blurriness or other problems resulting from inconsistent shade.

Cartridges are rated on a scale of 1 to 3 in each of the four classes. A score of 1 is perfect, with 3 as the worst rating. Therefore, 1/1/1/1 signifies the best rating. Auto-darkening welding helmets rated EN379-1/1/1/1 for optical clarity deliver even shade levels across the full height and width of the viewing area. They deliver little, if any, distortion of view − similar to viewing through clear, uniform glass. We have begun to incorporate this European standard into our helmet design and manufacturing process. For example, our Viking™ auto-darkening cartridges for the 1840, 2450 and 3350 series of helmets now offer a perfect EN379-1/1/1/1 optical clarity rating.

1/1/1/1 ELIMINATES GUESSWORK

Though not required in the U.S., understanding and selecting helmets that include such ratings is beneficial to the end user. The rating eliminates guesswork when trying on helmets or comparing helmets to find the best views. With such ratings offered, the user will know that a helmet with a 1/1/1/1 optical clarity rating will deliver a perfect view and the highest-quality lens. Optical clarity is noticeable in helmets with high EN379 ratings.

Experienced welders using 1/1/1/1-rated helmets report an immediate, noticeable difference in optical clarity over, for example, a helmet with a rating of 1/2/1/2 – clearer focus, improved overall vision and greater comfort. Welders using 1/1/1/1-rated helmets report that they see the arc with less distortion. Professional welders can and do notice the difference between a 1 and 2 rating, and will notice a much greater difference between 1 and 3. Obviously, differences in EN379 ratings play a role in overall productivity. Looking through a distorted lens with impurities and inconsistent shade causes eye strain and more difficult working conditions. Clear sight allows eyes to work longer with less fatigue and less overall body strain.

HELMET SELECTION BEYOND CLARITY

Optical clarity is one of many factors involved in welding helmet selection. Helmets are required to meet stringent safety standards. In North America, applicable standards include ANSI Z87.1 in the United States and CAN/CSA Z94.3 in Canada. Prior to purchase, users should confirm that the helmet meets industry and regulatory standards.

The type of welding to be performed also affects helmet selection. In various welding applications, amperage ratings generate varying light-emission levels that require differing shade levels. Thanks to quick-changing LCD (liquid crystal display) technology in the auto-darkening cartridge, advanced auto-darkening helmets protect from harmful light emissions at all times and darken to almost any pre-selected shade in milliseconds. Using such helmets, welders can see clearly while the helmet is in the down position. This allows weld setup to occur with the hood in position.

Advanced auto-darkening helmets optimize shading for optimal protection and greater comfort, offering full shade ranges, to 6-13 with additional grind modes. Welders frequently switching between welding processes and applications find these capabilities beneficial. It also is important to consider headgear style and adjustability, and overall weight. And be sure to consider whether the helmet can lower with a simple head nod, determine its hands-free operation and even the comfort of the built-in sweatband.

THE CLEAR CHOICE

As we can see, optical clarity plays a major role in the process of selecting an auto-darkening welding helmet. Where clarity once was hard to determine without trial and error, today it can be identified through quantifiable benchmarks and ratings. As demand for better optical clarity in auto-darkening helmets increases, welders increasingly will demand top-quality viewing capabilities from their eye protection.