Tube & Pipe Beveling

ESCO Tool introduces a new blade holder for the Prepzilla MILLHOG pipe beveling tool that permits beveling, facing, and boring simultaneously to assure high weld quality.

Posted: October 4, 2015

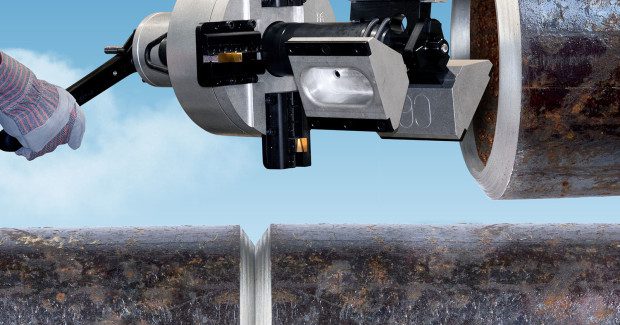

In Booth S-2361, a new blade holder for the Prepzilla MILLHOG® pipe beveling tool that permits beveling, facing, and boring simultaneously to assure high weld quality is being introduced by ESCO Tool Company (Holliston, MA). The Prepzilla MILLHOG ID Clamping pipe beveling tool machines pipes from 1.5 in ID to 8.625 in OD using only eight sets of clamps and one mandrel. Featuring a new, rigid three-blade holder designed to bevel, face, and bore in one operation, this end prep tool assures there is a smooth transfer when matching two different pipe schedules for optimum weld quality.

Suitable for highly alloyed materials, the Prepzilla MILLHOG ID Clamping pipe beveling tool can produce end preps at any angle without cutting oils. It has robust construction with dual-opposed tapered roller bearings, direct drive gears, a rigid blade lock system, and TiN coated T-15 tool steel cutter blades. Air- and electric-powered models are available. The Prepzilla MILLHOG ID Clamping pipe beveling tool, featuring a three-blade holder, is priced at $8,995 and is available for rent.

Also on display is a new blade holder for the Commander MILLHOG heavy-wall pipe beveling tool that includes a bore blade to create a more uniform ID and assure proper pipe end alignment. The Commander MILLHOG Pipe Beveling Tool machines heavy-wall, highly alloyed pipe from 3.75 in ID to 14 in OD, including Super Duplex and P-91. Featuring an optional 3-blade holder, this tool can bevel, face, and bore simultaneously, assuring a uniform inside bore to create a tight weld that X-rays well and a smooth face and bevel for proper pipe end alignment. Capable of performing any angle of end-prep including 37-1/2 deg and J-preps for orbital welding, the Commander MILLHOG Pipe Beveling Tool uses one mandrel and only seven sets of clamps for the entire range of the tool. Available with pneumatic or hydraulic motors, the oversize clamps have six contact points to mount securely for chatter-free machining end preps. The Commander MILLHOG Pipe Beveling tool is priced from $15,995, including tools and a metal carrying case, and is available for rent.

Also on display will be the Wart MILLHOG water wall boiler maintenance tool that mounts securely to the tube ID for removing membrane, cladding, and beveling simultaneously with minimal vibration. This boiler tube machining tool has a proprietary membrane and overlay cladding removal head that creates a clean bevel, all in one operation. Featuring a heat-treated draw rod assembly designed with clamps that expand on the mandrel and clamp rigidly to the tube ID, it machines water boiler tubes from 2 in to 3 in OD with minimum vibration. Equipped with attached clamping and ratchet feed tools, the Wart MILLHOG uses TiN coated cutter blades to machine highly alloyed or high chrome content boiler tubes without using cutting fluids. It has a sealed mandrel to prevent debris from entering the tool, dual opposed tapered roller bearings, and is offered with pneumatic or electric motors. The Wart MILLHOG, equipped with the membrane and cladding removal head and pneumatic motor, is priced from $5,795 and is available for rent.

The company will also introduce an upgraded welding end prep tool for machining high temperature, high pressure pipe used on severe-duty offshore piping systems and shale pumping stations. The MILLHOG Dictator Welding End Prep Tool is an ID clamping pipe milling machine designed for dry-cutting high-temperature, high-pressure pipe from 4.5 in ID to 18 in OD. Ideally suited for stainless steel and super duplex piping systems, this tool features a new 3 hp air motor designed for high performance in environments that have dirty air and high moisture content. Easy to clean and maintain the air motor by just removing one screw to access the rotor and vane assembly, instead of removing the motor from the tool, the MILLHOG Dictator Welding End Prep Tool develops 4,100 ft-lb of torque at the cutter blade and pulls a continuous thick chip without cutting oils. Blades are TiN coated and dissipate heat away from the pipe’s surface. The MILLHOG Dictator Welding End Prep Tool is priced from $21,995 and is available for rent from $850.00 per week, depending upon location.

Also on display will be a complete line of boiler tube expanders that automatically control tube expansion to assure precise wall reduction when fabricating and maintaining tube sheet. MILLHOG Rolling Motors and Tube Expanders are air-powered and feature a torque control setting which stalls the tool when it reaches the desired tube expansion to prevent over-under expansion. Enabling shops to create a uniform and tight mechanical seal, these tube sheet expanders are easy to adjust and allow precise torque control from 25 ft-lb to 325 ft-lb. Available with 90 rpm, 190 rpm, and 280 rpm motors, the right angle style MILLHOG Rolling Motors and Tube Expanders are offered as kits for tubes from 3/8 in to 4-1/2 in OD and tube sheets to 5-3/8 in. Supplied complete and ready to use with standard shop air, they are ideally suited for creating mechanical seals in boilers, heat exchangers, and condensers. MILLHOG Rolling Motors and Tube Expanders Kits are offered for sale from $4,695 up or for rent, with 24-hour shipment available.

Also on display will be an air-powered saw that can be used in any position to produce perfectly square cuts on water wall boiler tube panels made from highly alloyed tube up to 4-1/2 in OD. The APS-438 Air-Powered Saw features a proprietary abrasive blade that can rapidly cut all types of boiler tube alloys, including stainless steels and Inconel® with ±1/16 in accuracy and no HAZ (heat affected zone). Capable of cutting in any position, the saw glides effortlessly along the EscoTrack® system which attaches simply to boiler tube panels using two weld tabs. Featuring a 3 hp motor, the APS-438 Air-Powered Saw has an ergonomic design and mounts on the 5 ft steel EscoTrack system by a bracket with four grooved steel wheels that takes the weight off of the operator. It uses only 80 cfm 90 psi shop air and has a safety relief valve to prevent running at excessive speeds. Blades come in 10 in and 12 in diameter sizes. The APS-438 Air-Powered Saw is priced from $5,729 and is also available for rent.

ESCO Tool Company, 75 October Hill Road, Holliston, MA 01746-1344, 508-429-4441, Fax: 508-429-2811, www.escotool.com.