Welding Setup Redefined

Strong Hand Tools offers new equipment debuts that will help welders and fabricators setup metal accurately for greater quality and productivity.

Posted: October 28, 2015

In Booth N-26022, Strong Hand Tools® (Pico Rivera, CA), the manufacturer of Strong Hand Tools Welding Clamps, BuildPro Welding Tables, and the North American distributor of German-made Siegmund High Precision Welding Tables, announces their largest and most important group of new product debuts that will help welders and fabricators setup metal accurately for greater quality and productivity.

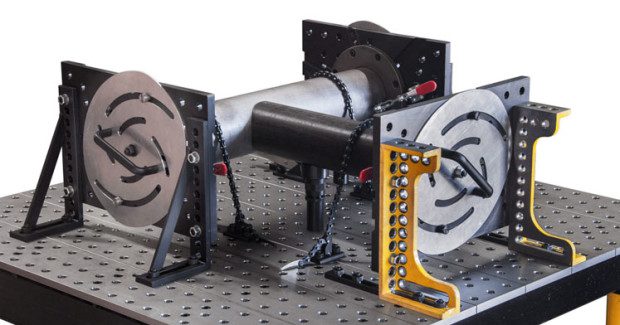

This all starts with the new Professional Extreme 750 Siegmund Welding Tables, the hardest, most durable, and extraordinarily flat welding tables available in the world. Constructed from premium through hardened steel, Professional Extreme 750 Welding Tables are finished with a newly optimized Plasma Nitride treatment, which results in a deep, hard case for a table that will last a lifetime. This unrivaled hardening process protects against stroke impact, and provides a more wear and corrosion-resistant surface with a glossy black shine for a table of superior quality and performance. Professional Extreme 750 tables have a surface hardness of 750 HV (~60 HRC). Shops can choose from System 28 (28 mm boreholes) or System 16 (16 mm boreholes).

Also on display are the new HD Ergonomic Height-Adjustable Electric Lift Platforms for use with BuildPro® Modular Welding Tables. Built in the U.S., these patented, vibration-dampening Lift Platforms smoothly glide up and down with the use of a simple to operate, programmable switch. The strong, rigid platforms are constructed from 11 ga / 14 ga thick steel columns with laser cut, welded horizontal supports made of ½ in HRS steel plates. The platforms offer an unparalled weight capacity range of 1,200 lb to 6,500 lb with a travel range of 12 in (from min 31.25 in to max 43 in height). The Modular bolt-together design (Grade 8 bolts, nuts and washers) allow knock down shipping, quick setup, breakdown, and reassembly/resize. These platforms can be safely locked in the stationary position or moved around the shop on 5 in HD retractable casters. The HD 70 mm square legs are CRCSCA 1010-11 gage high tolerance steel tubing. The durable powder coat finish is applied to withstand 750 hours of salt spray testing. Shops can increase worker comfort, safety and productivity by setting their BuildPro Modular Welding Table at the ideal working height for each new project.

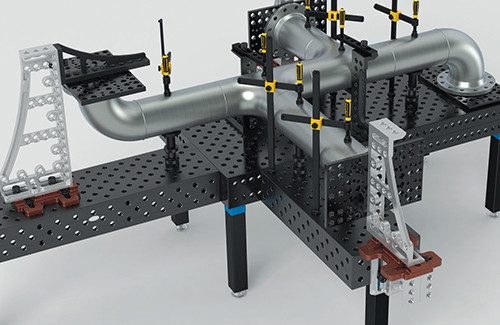

Also on display is their new Universal Flange and Pipe Fixture that enables fabricators to reduce setup time in flange and pipe joining and increase weld quality for greater repeatability. Flanges in a diameter range from 3 in to 18.3 in and Hole Count from 4 to 16 can be accurately located and securely clamped to the Universal Flange Fixture Plate in setup for flange and pipe joining. Two Guide Blocks, set as required for each specific flange diameter and hole pattern, hold the flange against the Fixture Plate and expand symmetrically to accurately locate the flange. Pins in the two Guide Blocks provide easy flange loading.

The patent-pending Fixture Plate provides full welding clearance, and allows easy removal of the finished weldment. This fixture is strong and rigid to withstand cumulative stresses resulting from welding. It holds the joined flange and pipe during cool down to prevent distortion, expansion, and contraction. Load the flange and pipe, accurately position, and unload quickly for quality welds, maximum productivity, and repeatability. Multiple Universal Flange and Pipe Fixtures can be used for T-Pipe setups.

Also being debuted are the Strong Grip Pliers. Far from the ordinary, Strong Grip Pliers feature a crank handle for super-fast opening, closing, and tightening of the Pliers. The large crank handle even includes a hanging hole for pegboard storage. The unique Hammer Head model, with a serrated C-Jaw, features a light duty hammer for on-the-spot hammering, nudging, or tapping when you don’t have a hammer nearby. Deep grip marks on the top and bottom jaws provide positive gripping power. The secure adjustment bar minimizes those aggravating, time-wasting bar pop-outs. Designed and built for comfort, convenience, and fast operation, Strong Grip Pliers have an easy-reach, smooth release trigger that quickly unlocks the Pliers with one hand, and won’t pinch fingers. Models in the Strong Grip Pliers line include Hammer Head, C-Jaw, Dual-Axis Pull, Economy Pipe Pliers, U-Prong, Long Nose, and Sheet Metal Pliers.

Also being displayed is the new Pipe Alignment Clamp with Quick-Acting Jaws. This fast, accurate fit-up clamp has a rugged frame for use in the shop, or at the job site. Quickly set the jaws for each project with the unique Quick-Acting Jaws. Get a well-balanced hold on the Pipe Alignment Clamp by grasping the wide handle, while pressing the Quick Acting Button. The T-handle screw smoothly glides up and down, for fast jaw opening and clamp removal after welding. The ease of handling makes this clamp ideal for insertion and extraction at any point over long pipes. Stainless Steel contact points allow for clamping of Stainless Steel parts. Choose from two clamp sizes: small (6 in capacity) or large (12 in capacity). Shops can align pipe for joining, or pipe to flange, pipe to fitting, pipe to tee.

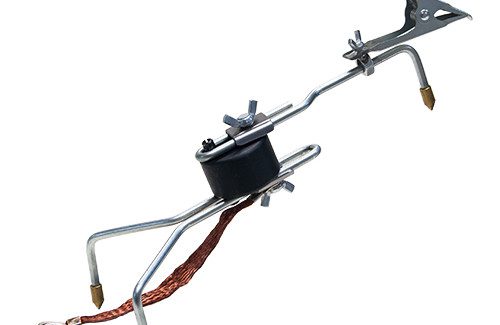

Also on display is the new Grasshopper Clamping Tool, a safe, convenient way to steady small parts for tack welding. Shops can steady small parts such as bolts, nuts, tabs, and thin metal plates for tack welding at odd angles with full welding clearance. Welders frequently resort to holding small parts in tight or narrow areas with their fingers. The Grasshopper, frequently referred to as a “Welding Finger,” performs this function safely and efficiently. The brass tips of the Grasshopper rest against even the smallest, thinnest metal or Stainless Steel parts. Adjust the Grasshopper by sliding the upper arm or leg base against the weighted body to provide the proper stability and balance in each unique tack welding setup. The PRO Model Grasshopper, Part No. AGH130P, includes three brass tips, a grounding ribbon, and a Spring Clip attachment for holding small rods or steadying thin metal plates.

Strong Hand Tools, 7141 Paramount Boulevard, Pico Rivera, CA 90660-3769, 800-989-5244 Ext 213, www.stronghandtools.com.