Automated Precision Beveled Holes in Vessels

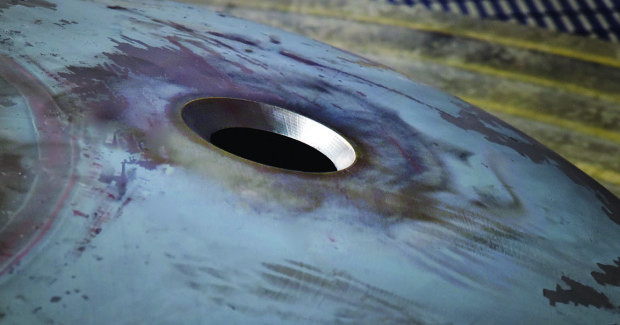

The Vessel Cutting Machine from HGG cuts precision beveled holes in pressure vessel tank heads, shells, nozzles and reinforcing pads, and hillside holes.

Posted: November 4, 2015

In Booth S-1999, HGG Profiling Equipment BV (Charleston, SC) recently introduced the Vessel Cutting Machine that is specially created to cut precision beveled holes in pressure vessel tank heads, shells, nozzles and reinforcing pads, as well as hillside holes. The Vessel Cutting Machine features a specially designed rotating table and a laser scanner system. The rotating table positions the vessel part under the cutting area. The laser scanner then scans the surface to measure the slope and adjusts the torch height to insure a proper bevel and root opening.

The Vessel Cutting Machine can be ordered in various sizes from 24 in to 13 ft diameter. Its cutting process tool can accommodate an oxy-fuel torch or plasma torch, and an optional fume collection system. HGG has designed their standard Vessel Cutting Machine solution to interface with and include the HGG SPC Series (Stationary Pipe Cutting Machine). It is also available as a stand-alone machine.

The Vessel Cutting Machine automates and integrates key elements and benefits of vessel making into one machine, including work preparation, outlining (measuring and marking), cutting and beveling. The Vessel Cutting Machine is capable of cutting all essential parts of any vessel, including shells, heads, nozzles, as well as reinforcing pads, all with perfect weld preparation. HGG defines this capability as FitPerfect technology, which includes an extra axis to bypass the need for shell rotation, a CAD interface for easy creation of cutting data, a 360 deg camera interface for checking the thermal torch when the operator cannot see it, and laser triangular measurement that adapts the 3D cutting path to deviations of the raw material.

HGG, headquartered in Wieringerwerf, Netherlands, is a leading supplier of pipe cutting machines, robotic profile cutting lines and associated cutting equipment solutions around the world, with subsidiaries in the Philippines, China, India, the Middle East and, most recently, in the United States in Charleston, where they provide comprehensive sales and service support for the company’s growing customer base in North America, Central America and South America in steel construction, piping process industries, offshore/onshore, crane building, ship building and others.

HGG Profiling Equipment BV, 5519 Indigo Commons Way, Charleston, SC 29418, 330-461-6855, jt@hgg-group.com, www.hgg-group.com.