Next Generation Sheet Handling Technologies

Industrial Magnetics offers the new Sheet Seeker permanent magnetic sheet fanner and advanced Transporter magnetic technology.

Posted: November 4, 2015

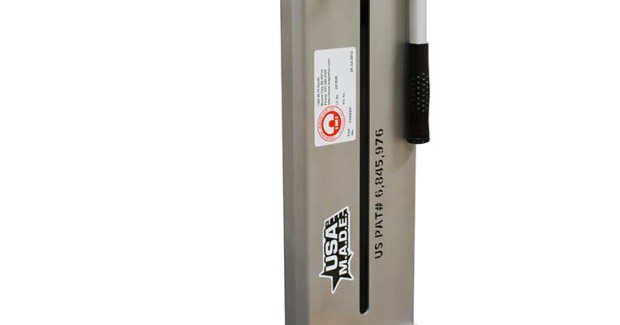

In Booth S-2112, the new Sheet Seeker® from Industrial Magnetics, Inc. (IMI; Boyne City, MI) is a permanent magnetic sheet fanner that revolutionizes traditional designs for a 60 percent decrease in weight and greater portability between metal stacks. The unit features a patented sliding mechanism that allows the powerful rare earth magnetic circuit to index down automatically as metal sheets or blanks are removed from the stack. By focusing the magnetic circuit only where it’s needed, the overall weight of the unit was reduced by 60 percent, while maintaining the same fanning strength.

Capable of fanning 30 ga sheets to 3/16 in plate, the Sheet Seeker is available in 12 in to 24 in heights and is constructed of durable stainless steel. All models feature a convenient carry handle for user-friendly transport and safe and efficient mid-stack changeover of blanking lines. Custom designs and options are available upon request, including an on/off magnetic base with roller cam release in place of a standard mounting bracket.

Also on display will be the patented Transporters® that magnetically transfer metal blanks, stampings and parts in automated station-to-station, press-to-press transfer or robotic pick-and-place applications. Engineered with powerful Rare Earth magnets that positively hold the part during transfer – even during unexpected loss of shop air – the Transporter family greatly reduces chances for slipping and shifting of parts due to mill oil coatings, dust, dirt, rust or weld splatter. Transporters also provide more options for pick-up points on stamped, perforated and odd-shaped parts, and offer a significant reduction over vacuum and suction cups in shop air costs. In addition, all three lines in the Transporter family offer more accurate placement on the die and quicker cycle times for increased production.

The Original Transporter is designed for use on heavier gauge, non-flexing parts and uses a single burst of shop air to actuate the magnet on and off. It is available in three standard sizes, with holding capacities up to 670 lb. The Transporter LP allows for minimal die clearance and can be easily installed to existing air connections on tooling booms or robotic face plates. Transporter LP magnets are designed to directly replace vacuum cups with only minor tooling adjustments. Ideal for applications in the appliance, automotive, and office furniture industries, as well as numerous other material handling applications, the Transporter LP is next generation sheet handling technology. It only requires a short, single burst of shop air to quickly release parts and is available in three standard sizes, with the strongest unit holding up to 162 lb. Included in the LP line is the TPLP50, a 5 in low-profile Transporter that is ideal for lifting thin sheets. It is also available with a destacking option that features a special magnetic circuit, designed to destack metal sheets as thin at 0.030 in (22 ga).

The latest addition to the Transporter family is the Transporter MV (MagVac) end-of-arm tooling that combines vacuum and magnet technology to lift and hold all shapes and types of steel in stamping, blanking, and press-to-press transfer applications. The Transporter MV is ideal for facilities with mixed-use metals, where the magnet can be utilized in conjunction with the vacuum for ferrous parts and the vacuum can work on non-ferrous materials, eliminating downtime for tooling changes. Each Transporter is million-cycle-tested for endurance and incorporates a fail-safe feature that, in the event of air loss, prevents the magnet from releasing ferrous parts. IMI specializes in custom designs, providing Transporter product for coil lifting, banded material handling and other challenging applications. A full line of accessories and fittings are also available.

Industrial Magnetics, Inc., 1385 M-75 South, Boyne City, MI 49712, 231-582-3100, www.magnetics.com.