Panel Benders vs. Press Brakes

Bending vs. Folding: Does your shop have the right machine for the job?

Posted: November 7, 2015

When it comes to the forming portion of a production line, the first machine that comes to mind is usually a press brake. This is a go-to method for bending material into the part’s final shape or form. What some manufacturers are learning is that there is another viable solution for forming parts: a folding machine.

Commonly known as a panel bender, this machine can produce many of the same geometries as a traditional press brake, but has the added benefit of making some parts much easier to produce – all with standard tooling. A panel bender traditionally features a pair of blades which form flanges in the horizontal direction while a set of blank holders holds the material steady. This design enables panel benders to produce some parts much more efficiently, and even create bends that would require special tooling on a press brake. As is the case with many fabricating technologies, not every part is ideally suited for a folding machine. In this article we’ll take a look at what parts lend themselves to panel benders and which are better produced on a press brake to help you decide if a folding machine might be right for your application.

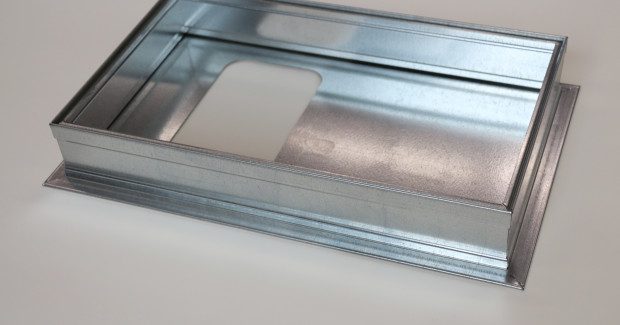

BOXES

Anyone familiar with folding machines knows the unmatched speed of a panel bender when it comes to producing a traditional box form. Due to the way a panel bender produces a bend, these machines can produce boxes, lids, and other similar shapes in a very quick and precise fashion. Since a panel bender can bend the entire side of a box at once, it can even handle return flanges on a box with ease. Press brakes can also produce boxes without a problem, but it is often an operator-intensive process with tool setup and part manipulation throughout the sequence of producing a complete part. A folding machine can typically form a part in half the time an operator can produce the same part on a press brake; however there are limitations.

For example, the panel bender is limited by the depth of the box. In situations where the box is too tall for a panel bender, a press brake can often be used. This is often due to the limited throat depth and open height on the panel bender.

LARGE PANELS

Large parts of different profiles also tend to be good candidates for a panel bender, not necessarily for the complexity of the part, but because any panel of significant size often requires multiple operators or a secondary crane to support any forming done on a press brake. With a panel bender, the blank can be loaded onto the working table and formed with minimal handling by a single operator. The advantage of a panel bender is easily seen with these parts, especially if the machine is able to automatically set up the blank holders.

SMALL PROFILES

Parts with intricate geometries can become a safety hazard when they are bent on a press brake. These geometries often force the operator to have his fingers very close to the tooling, creating a potential safety hazard. This threat is non-existent with a panel bender as the machine performs the part handling. A semi-automatic panel bender (i.e. a machine without a part clamp to maneuver the part during bending) is even more advantageous when bending intricate geometries since the operator can manipulate parts during the process. This allows the machine to produce more narrow profiles.

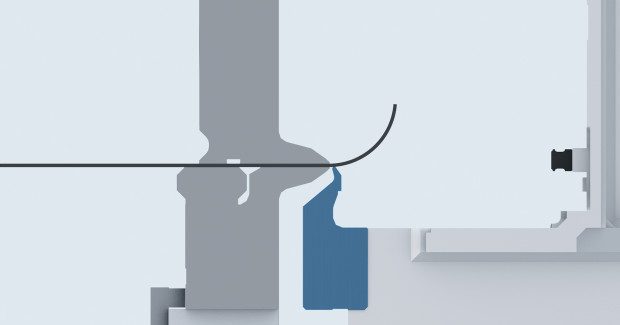

INTERNAL BENDS

With internal bends, a panel bender shows its limitations. The most common part that is problematic for a folding machine is one that resembles a frame and has internal bends in the geometry. These internal bends are typically hard to produce on a panel bender due to the location of the blank holders and bending blades. However, there are panel benders in the market that allow auxiliary tooling to produce internal windows on parts. Determining whether or not these higher-end machines will work then becomes a matter of part geometry.

RADIUS BENDING

A significant advantage can be gained by processing parts with varying radii on a panel bender. With a press brake, a large radius tool or even bar stock can be used to form a radius on a part. With a panel bender, the standard bending blades can produce multiple types of radii. These bends are often very aesthetic and often much cleaner compared to bump forming since the punch and die of a press brake tend to leave witness marks.

BENDING VS. FOLDING

We have covered a few examples of parts that lend themselves to production on a panel bender rather than a traditional press brake. There are many arguments for one machine or the other, so it is a good idea to take a look at the catalog of parts your shop creates on a daily basis, and analytically consider how many of your parts could be produced more efficiently with a new process. The world of folding machines, much like press brakes, is forever evolving and you may find you have a perfect application to justify a panel bender in your fabrication shop.