Advanced EDM Capabilities

This advanced equipment from Makino is ideal for aerospace manufacturers needing to produce a wide range of hole shapes and sizes within a single setup, significantly reducing required tool variety and overall cycle times.

Posted: January 21, 2016

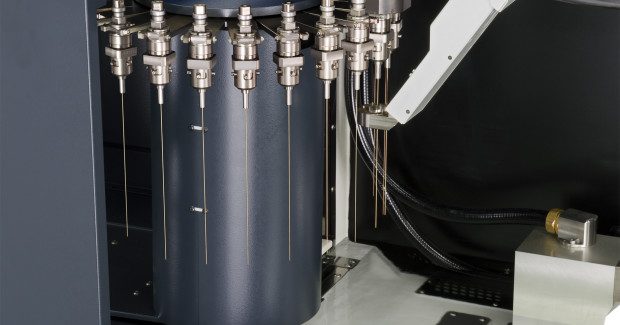

For discharge machining of cooling air holes and shaped diffuser holes in blade and vane segments, Makino, Inc. (Mason, OH) announces the new EDBV3 Fast Hole Drill EDM that provides aerospace manufacturers with the speed, flexibility and reliability to effectively produce a wide range of hole shapes and sizes within a single setup, significantly reducing required tool variety and overall cycle times. “The need for EDM drilling with advanced capabilities in blade and vane components has grown substantially due to new engine production requirements, as aerospace manufacturers strive to improve engine performance and reduce fuel consumption,” explains Brian Pfluger, the EDM product line manager at Makino. “The EDBV3 fulfills these needs by building on our proven EDM platforms with onboard filtration and resin systems and a user-friendly control system featuring preprogrammed hole profiles. Its 2-axis rotary table combined with automatic tool and guide change systems enable manufacturers to reliably machine complex features fully unattended, saving time and money, without risk to loss of part quality or accuracy.”

The EDBV3 offers X-, Y- and Z-axis travels of 370 mm, 270 mm and 500 mm (14.5 in, 10.6 in and 19.6 in), respectively, and worktable dimensions of 250 mm x 270 mm, with a maximum work piece weight load of 5 kg (optional 15 kg payload available). Its rotary C-Axis head features an EROWA compact chuck that enables automatic changing of electrode diameters down to 0.2 mm (0.008 in) and can spin up to 1,000 rpm. All EDM drilling on the machine is performed fully submerged under water for higher part quality, improved stability and up to ten times faster processing speeds than conventional technologies. To further improve productivity, the EDBV3 uses a single-electrode processing approach to avoid the high cost of custom multi-electrode holders and standardizes the tool holders with a more flexible and cost-efficient system.

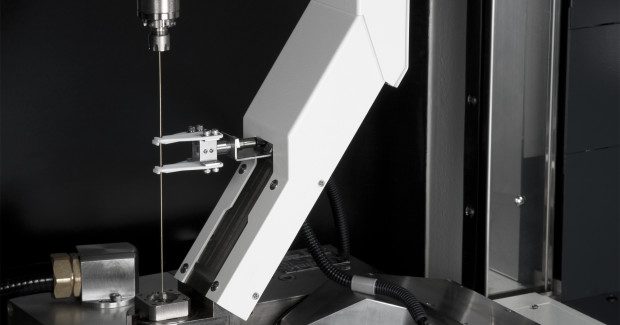

For unattended burning of varying cooling hole diameters, the machine features automatic tool change (ATC) and automatic guide change (AGC) systems. A patented electrode set that combines the electrode holder and die guide together into a common assembly provides enhanced reliability with simple and precise automated exchanges. Together, these features enable 30 second ATC and AGC exchanges. A rigid guide-arm assembly holds, locates and supports the die guide, which can be alternately used as a programmable axis (W-axis). An integrated “middle-guide” system can be applied for small-diameter electrodes, preventing whipping, bending and vibration. Additionally, the middle-guide “fingers” automatically retract as the electrode tube reduces in size, using as much of the electrode length as possible.

The standard configuration of the machine includes a 24-station tool carousel system and 24 holder assemblies to fully tool up the machine. The tool carousel can be exchanged as a palletized magazine for extended hours of automated operation. The machine employs several proven software technologies used in fine-hole sinker EDM machines. The Model Plan software system is integrated into the controller, providing user-friendly input screens with direct G- and M-code programming formats. An electrode length management system provides electrode wear tracking, and automatically exchanges electrodes when lengths become too short.

To prevent back-wall impingement during blade and vane cavity wall penetration, the machine includes a proprietary, highly sensitive breakthrough detection circuit. This sensing capability — accomplished while delivering maximum speed and productivity — uses a combination of different adaptive process-monitoring techniques. The machine’s fully submerged processing delivers additional support by allowing debris flushing during breakthrough, for a faster and more stable process.

Makino has also released the EDBV8 fast hole EDM drilling machine for the production of film cooling holes and shaped diffuser holes in blade and vane segments. This machine is ideally suited for large turbine engine component machining for the aerospace and power generation markets and is equipped with a 2-axis rotary table for enhanced workpiece positioning. The development of this machine marks the first expansion of the EDBV-Series (electrical discharge blade and vane) product line and provides blade and vane manufacturers with the flexibility to accommodate a wider range of part sizes for any high-volume fast hole EDM drilling application.

“The EDBV8 machine provides manufacturers with the speed, flexibility and reliability to effectively produce a wide range of hole shapes and sizes with a single electrode process,” notes Pfluger. “This approach significantly reduces tooling costs while improving cycle time, part quality and production efficiency. Its uniquely designed tooling system integrates the electrode and die guide into a common assembly for quick and reliable automated exchanges, and provides programmable control over electrodes and electrode diameter size changes.”

The EDBV8 offers X-, Y-, Z- and W-axis travels of 800 mm, 600 mm, 750 mm and 500 mm (31.5 in, 23.6 in, 29.5 in and 19.7 in), respectively. It is equipped with a 2-axis rotary table that can accommodate a maximum workpiece size of 500 mm (19.7 in) diameter by 635 mm (24.96 in) long, and a maximum payload of 150 kg (330 lb). Its rotating C-axis head features an EROWA compact chuck that enables automatic changing of electrode diameters from 0.2 mm (0.008 in) up to 6.0 mm (0.236 in) with rotation speeds up to 1,000 rpm.

A rigid guide-arm assembly holds, locates and supports the die guide, which can be alternately used as a programmable axis (W-axis) that runs parallel to the Z-axis. An integrated “middle guide” system is also contained within the W-axis and is used with long small-diameter electrodes to prevent whipping, bending and vibration of the electrode. The middle-guide “fingers” automatically retract as the electrode tube reduces in length, maximizing the productive useful length of the consumed electrode. “The need for EDM drilling with advanced capabilities in blade and vane components has grown substantially due to new production requirements, as turbine engine manufacturers strive to improve engine performance and reduce fuel consumption,” says Pfluger. “The EDBV8 fulfills these needs by providing solutions to larger, heavier workpieces, while improving productivity and part quality.”

The machine features improved flushing through fully submerged machining, greater machining stability and part accuracy, and faster cycle times with the equipped 10 MPa (1,450 psi) flushing capability for higher productivity of deep-hole features. The machine also contains a fast response break-through detection circuit to prevent back-striking or back-wall impingement (damage to the inner cavity) during blade and vane cavity wall penetration. This highly sensitive breakthrough detection circuit, which uses a combination of different adaptive process-monitoring techniques, is accomplished while delivering maximum speeds. An advanced EDM generator technology produces excellent metallurgical quality and integrity on high-nickel alloys such as Inconel®. Reliable and repeatable machining results are maintained using the machine’s on-board water quality control system that consists of a filtration system to clean the water, a deionization system to control water conductivity, and a chiller unit to maintain the water temperature at the same level as the machine casting.

For unattended burning of varying film cooling hole diameters, the EDBV8 features automatic tool change (ATC) and automatic guide change (AGC) systems. The patented tooling system combines the electrode holder and die guide together into a common assembly, providing enhanced reliability with simple and precise automated exchanges. Together, these features enable ATC and AGC exchanges in less than 1 minute, and they offer a unique combination of process flexibility while minimizing non-value added machine motions. The Model Plan software system is integrated into the controller for user-friendly input screens with direct G- and M-code programming formats. An electrode length management system provides electrode wear tracking and automatically exchanges electrodes when lengths become too short. The controller contains several canned cycles for hole drilling and simple diffuser shape machining, and custom G-Code profiles can also be imported and easily used in the machine.

This machine has been designed for easy operation and offers the operator unparalleled access to the work tank with its three-sided rise-and-fall work tank. It is also capable of on-machine probing to determine workpiece locations and offsets. Electrical touch-sensing probing or a conventional mechanical touch probe can be used to capture location data points. The standard configuration of the machine includes a 24 station tool carousel and 24 tool assemblies to fully stock the machine for maximum productivity.

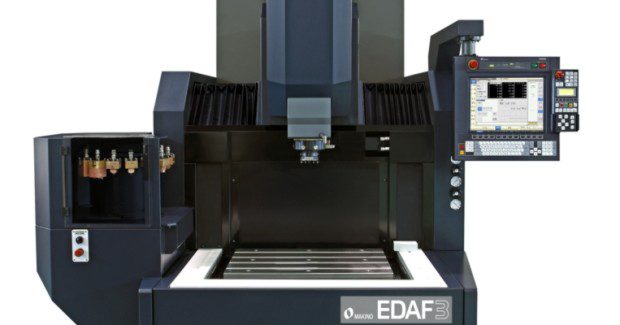

Makino has also introduced their latest Ram EDM machinery, the new EDAF Series that features a new mechanical design for increased rigidity and reduced thermal distortion that is ideal for manufacturers facing uncontrolled thermal environments and long hours of unattended burning. These machines are equipped with an improved servo system for rapid response to signals from the spark gap monitoring circuits, enabling cycle time reductions of 10 percent to 20 percent in burns common to today’s job shop applications.

The EDAF series features two models, the EDAF2 and EDAF3, with sizes of 53.2 in x 95.5 in x 98.4 in and 59.1 in x 102.4 in x 100.8 in with X, Y, and Z axis travels of 13.8 in, 9.8 in, 9.8 in and 17.7 in, 13.8 in, 13.8 in respectively. The EDAF2 provides worktable dimensions of 21.7 in x 13.8 in with a payload of 1,102 lb, while the EDAF3 offers table dimensions of 27.8 in x 19.7 in with a maximum payload of 1,764 lb. These machines are equipped standard with the most sophisticated spark gap monitoring and arc prevention technology available on the market today. New ArcFree Technology helps prevent destructive DC arcs that typically lead to time-consuming clean-up procedures or scrapped parts, allowing manufacturers to burn any application, fully unattended, worry-free. Even applications with unfavorable electrode/work piece geometry can easily be started with unusually high current density, and relied upon for flawless results.

Included in the EDAF series is a new on-board programming system, Makino Program Generator (MPG), designed to make the MGH control more user friendly while generating more aggressive model plans to meet the demands of shortened lead times on today’s shop floor. By providing answers to simple prompts, and inputting basic data, even novice operators will be able to generate efficient and safe burn routines. This new program generator also allows for programming of multiple electrodes and multiple burn locations. High Quality Surface Finish (HQSF) technology provides EDAF machines with improved electrical conductivity for more consistent discharging and spark diffusion. It eliminates secondary discharges that waste energy while permitting increased efficiency of the sparks for a superior finish without a loss in metal removal rates. HQSF allows for achievable surface finish capabilities that are 50 percent better than that of conventional achievable surface finishes, regardless of discharge surface area.

EDAF machines include several other standard and/or optional features:

- A dielectric fluid cooling unit to maintain dielectric temperatures to a constant setting for stable burning conditions.

- A new automated Power Saving Mode that reduces the machine’s power consumption by 70 percent while idle.

- A rise and fall drop tank design for user friendly part loading/unloading, faster, more accurate setups, and favorable automation capabilities.

- (Optional) A fine-hole configuration for precision machining of details smaller than the eye can see.

- (Optional) A thermal chamber for enhanced thermal control and performance accuracy.

- (Optional) Z-Axis Stabilizer technology for liquid cooling of the Z-axis ball screw and nut, allowing cavity floor surface blending to within one micron.

- (Selectable on factory order machines) Left or right hand control mounting options for easy integration of one or more machines into a robotically automated electrode or work-pallet handling cell.

Makino also offers general-purpose wire EDM technologies in the U3 and U6. Designed for ease of operation, versatility and low operating cost, the U3 and U6 are the true next-generation solution for improved profitability in wire EDM processes. “The U3 and U6 offer enhanced machine performance in a design that makes competitive cycle times and high degrees of accuracy and finish easy to achieve, no matter the condition or application,” states Pfluger. “With our HyperCut technology and Hyper-i control, even novice operators can program and produce leading-edge part finishes in the most complex feature geometries — a significant competitive advantage for shops experiencing difficulty replacing skilled EDM operators.”

The U3 and U6 offer X-, Y- and Z-axis travels of 370 mm by 270 mm by 220 mm and 650 mm by 450 mm by 420 mm, respectively. The U3 will accommodate a maximum workpiece size of 770 mm by 590 mm by 220 mm with a payload of 1,322 lb, while the U6 holds sizes up to 1,000 mm by 800 mm by 400 mm with a maximum payload of 3,307 lb. Other features of the U3 and U6 include reduced wire-consumption rates, dual digitally-controlled flush pumps and a choice of two wire-guide configurations — conventional round or Split V guide system — to accommodate any material types and flushing conditions from 0.004 in to 0.012 inØ wire (0.1 mm ~ 0.3 mmØ). An extensive cutting condition library provides optimized conditions for standard hard brass wires, high-speed coated wires and high-taper soft wires. The depth and versatility of the entire cutting condition library ensure that all applications can be machined at optimum productive levels.

The U3 and U6 feature an innovative design in which the entire bed casting is used as the dielectric reservoir. This design approach reduces floor-space requirements over previous models and eliminates the need for additional external fluid tanks. By merging all machine components into a single base structure, the U3 and U6 provide improved mechanical rigidity and thermal stability, and the stationary table design ensures sustainable long-term accuracy. Additionally, work-zone access has been simplified, for straightforward, ergonomic access and ease of maintenance.

Both the wire EDM machines are equipped with the Hyper-i advanced machine control that features a user-friendly interface similar to that found on tablets and Smartphones, making operation very intuitive. A 24-inch HD touch-screen display provides many intelligent functions, including onboard electronic manuals, instructional videos and a diagnosis tool, providing operators with all of the resources necessary to remain highly productive. The Hyper-i control can also be customized to individual operators and/or for certain shifts, and an optional dual display screen can be configured for use with an onboard CAD/CAM system.

With the U3 and U6, there are no special settings required to experience wire saving; every cutting condition, including sealed and poor flush applications, is automatically optimized and designed from the ground up for low wire consumption. Combined with the machines’ speed and accuracy, the U3 and U6 offer the highest level of overall efficiency, throughput and low operational cost. A unique Pro-Tech circuit provides electronic galvanic protection to the workpiece in order to prevent or minimize rusting and oxidation. This technology is standard on the U3 and U6 to preserve the integrity of the workpiece without the need for chemicals. The U3 and U6 feature HyperCut technology, a special three-pass process technology developed to produce surface finishes as fine as 3µm Rz in standard tool steels. This performance enhancement represents a 20 percent reduction in cycle time and 14 percent reduction in wire consumption, compared to previous technology. Together, manufacturers can expect significant saving in cost per part.

The U3 and U6 are both available in an optional High Energy Applied Technology (H.E.A.T.) configuration that incorporates higher pressure, dual digitally controlled flush pumps and a large capacity four-filter filtration system that together provide even faster machining speeds. H.E.A.T. is designed to provide unparalleled wire EDM machining speed and accuracy in parts featuring poor or difficult flushing conditions.

Makino also introduces the U53j, another addition to its family of Uj-Series wire EDM machines that is targeted to precision plastic injection molds, precision stamping tooling, and medical and micro-manufacturing applications. “The U53j takes accuracy and finish capabilities to a higher level,” says Pfluger. “It produces geometric accuracies of ±0.0001 in (0.003 mm) and surface finishes down to 1.3µRz / 0.13µmRa / 5µinRa in tool steel and 0.9µmRz / 0.09µmRa / 3µinRa in carbide.”

The accuracy and finish capabilities are achieved and maintained due to the mechanical accuracy and technology advancements built into each machine. Precision alignment of all components for straightness, squareness and perpendicularity are mechanically scrapped to within 3~4 microns during machine construction and assembly, which provides long-term sustained accuracies with minimal reliance on electronic compensation. The stacked cube design of the U53j eliminates any possibility of overhang of any cast units when the axes are run to their full travel limits, and the work piece and work table remain stationary. This design helps maintain straight, precise movement while eliminating droop as the axes move through their full travel. X- and Y-axis ballscrews are 32 mm, anchored at both ends, and laser aligned to high-precision linear motion guides.

The U53j machine travels for the X-, Y- and Z-axes are 21.6 in (550 mm), 14.6 in (370 mm) and 8.7 in (220 mm), respectively. The machine can accommodate a maximum workpiece size of 37.8 in by 27.2 in by 8.7 in (960 mm by 690 mm by 220 mm, respectively), with a maximum workpiece weight of 3,307 lb (1,500 kg). The U53j utilizes a programmable 3-sided drop tank that offers outstanding accessibility. The drop tank system improves operator ergonomics and all aspects of work piece loading/unloading, part setups, and machine maintenance access. The drop tank also simplifies automation and tooling requirements, as the tank drops below the work table height, allowing for open 3-sided access.

The wire diameter range is 0.002 in to 0.012 in (0.050 mm to 0.300 mm). Using an improved automatic wire threading system, the U53j performs automatic wire threading in ten seconds in high-speed mode, and 15 seconds in fine-hole mode. The U53j comes standard with Split precision V guides that are ideal for easy maintenance and provide a guaranteed guide life of 12,000 machining hours. Also available are PICO precision wire guides, recommended for auto-threading holes smaller than 0.025 in diameter and/or with hole centers closer than 0.060 in. PICO precision wire guides are also recommended for machining complex, variable land details in precision lead-frame stamping die work.

The U53j utilizes a compact and space-savings design that uses the entire base casting of the machine as the di-electric reservoir, which enhances thermal stability. The interior structure of the machine is also kept to the same temperature as the dielectric fluid by means of a radiator system, which is controlled by the standard dielectric fluid cooling unit. This non-variance in temperature reduces thermal distortion of machine components and the workpiece to provide high-accuracy machining. Moreover, the dielectric fluid cooling unit incorporates an inverter system to minimize the temperature difference between its on/off states. The temperature is controlled with high accuracy to within plus or minus 0.1 deg C (0.18 deg F).

Makino has also announced its new HS-Rib high-speed Z-axis technology for improved speed, lower electrode wear and more uniform finishes in large sinker EDM processes. When it comes to reducing sinker EDM cycle times, it is not the maximum jump speed that is important, but rather the acceleration speed. High-speed Z-axis technology has a jump rate four times faster and Z-axis acceleration rate 30 times faster over previous technologies. This capability produces a more efficient hydraulic effect during machine processing, which helps evacuate debris from the spark gap, even in deep-rib features.

“As with all machining processes, there’s an insatiable desire to reduce cycle times while meeting part-quality requirements in sinker EDM processing,” added Pfluger. “Fulfilling these needs involves a number of considerations, including how to process for best speed and efficiency, minimize electrode manufacturing requirements, and reduce electrode wear to achieve the best possible surface finish quality. Our new high-speed Z-axis technology, combined with SuperSpark IV, helps support these factors, providing an ideal balance for efficiency in both electrode consumption and cycle times without the need for external auxiliary flushing.”

High-speed Z-axis technology is available on all EDNC-Series sinker EDM machines and is designed for use in large workpiece applications requiring high accuracy and fine surface finishes. Its design offers highly flexible processing capabilities, including a jump rate of 20 m per minute with 1.5 G acceleration, Z-axis strokes ranging from 500 mm to 800 mm, and programming of orbital machining patterns with no amperage limitations. The use of direct-drive motor technology and liquid cooling within the Z-axis structure ensures sustained thermal stability and precise depth control, and supports electrode weights of up to 100 kg (220 lb).

Four process strategies are offered for optimal performance based on users’ unique requirements for speed, surface quality, accuracy and electrode wear:

- Low Wear Settings: Provide a single-electrode rough and finish process

- Advanced Orbit and Jump Settings: Improve machining speeds and surface finish consistency

- High-Speed Z-Axis: Improve machining speeds and accuracy

- Aggressive Power Settings: Optimize machining speed (sacrifices electrode wear)

EDNC-Series sinker EDM machines combine rigid and precise construction, simple programming and advanced performance features for accurate processing of large workpieces. Equipped with the new high-speed Z-axis technology, these large, heavy-duty machines can produce deep ribs as fast as, or faster than, the smallest sinker EDM machines on the market. Automatic tool change and adaptive controls enable high levels of unattended machining without the need for operator intervention, and is further supported with advanced automatic jump machining controls to optimize debris removal without the need for external flushing.

EDNC sinker EDMs are designed with several friendly and efficient features. The machine uses a space-saving design that incorporates the dielectric reservoir into the base casting, which saves on floor space while also improving the thermal stability of the machine. Most EDNC-Series machines have a full three-sided programmable drop tank with unparalleled ergonomic access to the machine for setups and operation. All machines feature fully automatic fire-suppression systems, and use a special UV sensor that affords an excellent first line of defense for added operational safety. Programming can be performed using the menu-driven touch screen advanced model plan or streamlined MPG conversational format systems. Both methods offer simple selection of machining conditions for workpiece and electrode material type, and the desired feature shape and surface finish. The machine also is designed with advanced menu-driven 2D and 3D orbital motion techniques that provide high accuracy and uniform surface finish results over the entire workpiece detail regardless of complexity.

All EDNC-series sinker EDMs can be equipped with proprietary HQSF technology that yields achievable surface finish capabilities 50 percent better than that of conventional surface finishes, regardless of discharge surface area. Even when machining to standard/conventional surface finishes, the HQSF technology can yield a double-digit saving in cycle time.

Makino, Inc., 7680 Innovation Way, Mason, OH 45040-8003, 513-573-7200, Fax: 513-573-7360, brian.pfluger@makino.com, www.makino.com.