CAD/CAM Integrated Press Brake Software

Radbend 2016 press brake software closely links CAD/CAM, Radbend, Radm-ax and Radtube functions with a new style of program and file-type icons for a more unified feel.

Posted: January 7, 2016

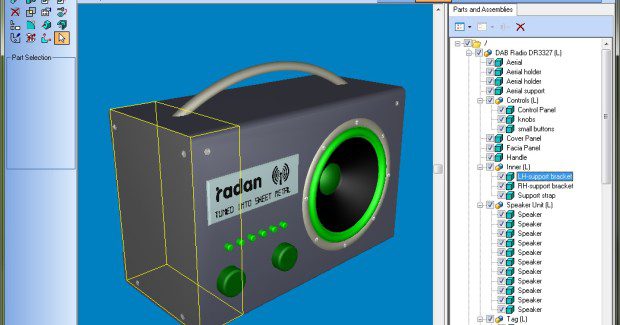

The new Radan 2016 suite of sheet metal software from Radan (Forest Lake, MN) uniquely combines applications for PC-based CAD/CAM punching, profiling, bending, nesting, designing and production management. Inside this suite is Radbend 2016 press brake software that closely links CAD/CAM, Radbend, Radm-ax and Radtube functions with a new style of program and file-type icons for a more unified feel. “There is a major connection between 3D in CAD/CAM and the Radbend press brake software,” explains product manager Olaf Körner. “When shops unfold a model they need to know how the bend process will be affected further down the production line. And when we bring in a 3D file we don’t know what’s in it; there might be a tube, or something that needs to go to the Radm-ax 5-axis laser system. So technologically it made sense to bring the products much closer together.” Radbend 2016 includes four major items of new and enhanced functionality:

- Simulation with result. Collision checking is more accurate, as simulation can now be performed using a modified part, rather than the designed part. “Sometimes designers create theoretical models, which may not be possible to make when they get to the press brake,” notes Körner. “In Radbend 2016, the software gives the press brake a better idea of what the manufactured part will look like, and will physically change it. With previous versions, the simulation used the designed part, but it now uses the modified model, so it’s more accurate and flags any issues much earlier in the process.”

- Manual tool selection. Optimizing Radbend’s strong automatic tool selection, users can now manually select tools more efficiently. “When Radbend automatically calculates a tool set, it’s accurate for producing the part,” states Körner. “But that’s always in isolation, and it may be possible to use the tool set already on the machine that produced the previous part. For example, if you need to have one bend on a part that is 25 cm wide, it’s often possible to use a tool that is wider than that. If that tool is already on the machine, this will save considerable set-up time.”

- Progress bars. “Some calculations can take a while to execute, so we have provided progress bars to keep the user informed about which part of the complex calculations are being dealt with,” adds Körner.

- Support for more machine tools. Radbend 2016 supports nine additional machine tools, either new controllers or models.

https://youtu.be/tS5KmH5V7cA

Radan, 25 North Lake Street, Suite 220, Forest Lake, MN 55025, 800-875-7232 ext 5551, radansales@radan.com, www.radan.com.