Hybrid Multi-Tasking Technology

Ideal for small lot production of difficult-to-cut materials used in aerospace applications, the Integrex i-400AM hybrid multi-tasking machine from Mazak can easily generate/clad near-net-shape component features, then quickly complete them with high-precision finish machining operations.

Posted: January 9, 2016

Mazak Corporation (Florence, KY) has unveiled its new Integrex i-400AM (additive manufacturing) hybrid multi-tasking machine. As a fusion of additive technology and the most advanced multi-tasking capabilities, this machine will significantly reduce part cycle times while providing high-efficiency Done-In-One® processing. As a turnkey system, the Integrex i-400AM offers manufacturers a new innovative alternative to conventional processing in terms of part design and machining. The technology is especially well suited for small lot production of very difficult-to-cut materials used in the aerospace applications. With the additive capability, manufacturers can easily generate/clad near-net-shape component features, then quickly complete them with high-precision finish machining operations – as well as laser mark parts if needed.

In operation, the Integrex i-400AM melts metal powder using fiber laser heat. Cladding heads (additive manufacturing nozzles) apply the molten material layer by layer, each of which solidifies as the desired shape grows. Plus, the system can join different types of metals to one another, a capability beneficial in the efficient repair of existing worn or damaged components, such as aerospace turbine blades. Cladding heads store in the tool magazine, and the standard automatic tool changer loads them into the machine’s milling turret. Mazak offers two types of cladding heads: high speed or high accuracy. Users select the appropriate head based on the intended process and the particular metal powder to be used.

On the multi-tasking machine side, the Integrex i-400AM provides full 5-axis capability to easily process prismatic parts from solid billets or castings (chucked or bar fed), round parts, highly contoured parts and now those with features built using additive technology. The machine provides -30/+210 deg B-axis movement in its milling spindle, full C-axis contouring with its turning spindle and an NC tailstock that is fully programmable.

For other complex aerospace part production, Mazak offers the Integrex i-200ST multi-tasking machine featuring the new Mazatrol SmoothX CNC that uses MTConnect as the communication standard for an entire factory. The small-footprint Integrex i-200ST features dual turning spindles, a lower turret and milling spindle for Done-In-One production of mid-size complex components up to 25.9 in diameter. Both turning spindles provide equal high performance with spindle speeds of 5,000 rpm and C-axis turning control. Each also has a maximum bar work capacity that measures 2.56 in diameter.

For C-axis contouring versatility at either turning spindle, the vertically mounted 30 hp, 12,000 rpm milling spindle has a rotating B-axis range of -30 deg to +240 degrees. The unique roller cam drive for the B-axis ensures higher accuracy and rigidity, while providing zero backlash. The machine’s lower drum turret carries nine tools and can work at either the main or second spindle with the same tool, allowing the turret to perform balanced cutting operations on one part working in tandem with the machine’s vertical milling spindle. There is also the option for milling capability with the lower turret.

The Integrex i-200ST uses the latest for complex, multi-axis machine tools that can achieve maximum speeds up to four times faster than previous generation controls. The SmoothX CNC coincides with the new Smooth Technology process-performance platform that spans the entire part-production landscape, from programming to metal removal to data collection. As a result, aerospace part manufacturers can dramatically shorten machine cycle times, enhance simultaneous 5-axis operations and more. With a minimal floorspace requirement of 193.3 in x 110.2 in and modern ergonomic design, the Integrex i-200ST allows for easy installation and hassle-free maintenance. Plus, the machine’s standard 36 tool and optional 72 tool changers are front-mounted for quick access. All of the machine’s lubrication points and gages are gathered into a single panel for ease of viewing and upkeep.

Mazak offers more high level multi-tasking capabilities in the Integrex i-100ST that employs two turning spindles, a milling spindle and a lower turret that make it possible for shops to accomplish first and second machining operations simultaneously or perform required sequential operations on a single workpiece. Able to handle all processes from raw material input through the final machining, the Integrex i-100ST provides dramatic reductions in lead-times and improves part accuracy through the elimination of multiple setups. Its full 5-axis capability makes it easy to process fully prismatic parts from solid block or castings, round parts or highly contoured sculptured parts as chucked or bar fed work.

https://youtu.be/5kFs1xGFFgM

The turning spindles on the Integrex i-100ST share high performance capabilities as they both employ a 15 hp integral motor spindle with maximum spindle speeds of 6,000 rpm. Each spindle features a 6 in chuck with a 2.4 in bore size that can accommodate bar stock of up to 2 in diameter. The machine’s powerful 10 hp, 12,000 rpm milling spindle mounts in the rotating B-axis and has a range of 240 deg in 0.0001 deg indexing increments. And for high accuracy of motion, B-axis scale feedback comes standard on the machine. The 36 tool magazine accommodates tools up to 5.1 in diameter when neighboring stations are empty and up to 3.5 in diameter when stations are occupied.

The lower drum turret on the Integrex i-100ST holds nine tools and can work at either the main or second spindle with the same tool, allowing the turret to perform balanced cutting operations on one part working in tandem with the machine’s vertical milling spindle. It is also possible to perform milling operations with the lower turret. The Integrex i-100ST easily integrate with various forms of automation, including bar feeders, gantry loaders and robots.

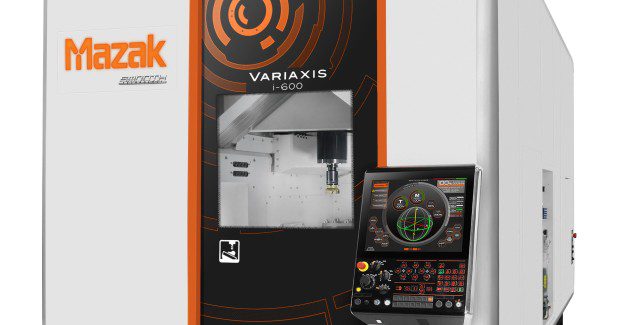

Mazak also offers the highly versatile VARIAXIS i-600, a full, simultaneous 5-axis vertical machining center that performs multiple and complex curved surface machining on small and medium-sized workpieces in single setups. The machine falls within the Done-In-One concept by incorporating all processes, from raw material input through final machining, in just one machine. As such, the machine reduces production lead times, improves machining accuracy and lowers operating expenses. It also offers high levels of productivity via extremely fast, high-rigidity spindles that can handle a wide variety of applications, from heavy-duty cutting to high-speed cutting of aluminum and other nonferrous material.

https://youtu.be/jRjjmEBYkwg

An optional two-pallet changer provides continuous machine operation and integration within a Palletech Manufacturing System for automated manufacturing. Other features include:

- Wide range of spindle speeds available for exceptional versatility.

- Reliable cam-driven tool changer offers higher productivity.

- Tool storage capacities up to 120 tools.

- High-rigidity table with roller gear cams eliminate backlash to ensure accuracy.

- MX Hybrid Roller Guide System offers durability and reliability for long-term accuracy.

- Matrix 2 CNC control provides unbeatable accuracy and increased productivity.

Mazak Corporation, 8025 Production Drive, PO Box 970, Florence, KY 41042, 859-342-1700, Fax: 859-342-1865, www.mazakusa.com.