Innovative Cutting at an Affordable Price

These fiber laser cutting systems offer outstanding cut quality on thin to medium thick steel, stainless steel, aluminum, copper and brass sheets.

Posted: January 7, 2016

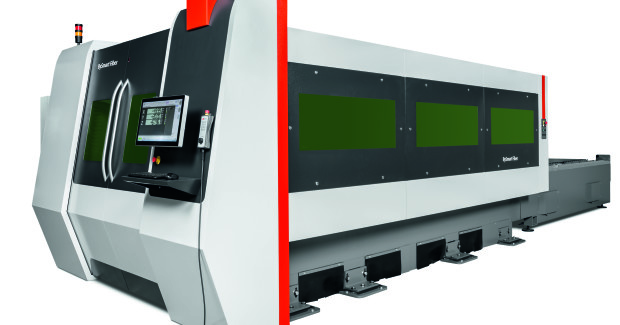

The new BySmart Fiber 3015 compact laser cutting machine from Bystronic Inc. (Elgin, IL) is an innovative machine designed for first-time users who are looking for high quality performance at an affordable price. This is their opportunity for a fast entry into fiber laser cutting technology. The newly developed machine platform delivers outstanding cutting results with just a few operating steps. To achieve this, the BySmart Fiber’s performance package focuses on the core competency of a fiber laser: laser cutting parts in the most simple and cost-effective manner possible.

In the thin range of sheet thicknesses, the BySmart Fiber uses the full potential of fiber laser technology to significantly speed up the cutting process compared to a CO2 laser. But it also proves its qualities in higher sheet thicknesses. Users also benefit from comparably low operating and maintenance costs. So for shops whose range of jobs lies primarily in thin material applications, this means faster cutting processes, lower costs, and higher profits with every cut part. BySmart Fiber 3015 is available with a Fiber 2000 or Fiber 3000 laser source to process a wide range of materials and thicknesses, from steel and stainless steel to aluminum and non-ferrous metals such as copper and brass. Moreover, the fiber laser optics’ thin cutting beam enables extremely fine contours to be cut with outstanding cutting quality.

Operators control the cutting process on the BySmart Fiber using a 22 in touch screen. The powerful ByVision user interface controls the entire manufacturing process with just a few swipes of the finger. ByVision accesses an extensive database that includes the parameters for all the common types of sheet metal. Taking the material, sheet thickness, and part geometry into account, it creates the ideal cutting process. While cutting, ByVision monitors all of the processes on the machine and provides the user with the most important process and machine data on-screen. This means the user always has an overview of all the relevant information: the current cutting plan, the position of the cutting head, and the machine status.

With the BySmart Fiber, shops not only get a fast fiber laser, they also gain access to the BySoft 7 software package that ensures the laser cutting system’s seamless integration into the user’s process chain. This allows the overall concept of an optimized manufacturing environment to be established around the fiber laser, in which users can realize the finished sheet metal part in a fast and efficient process.

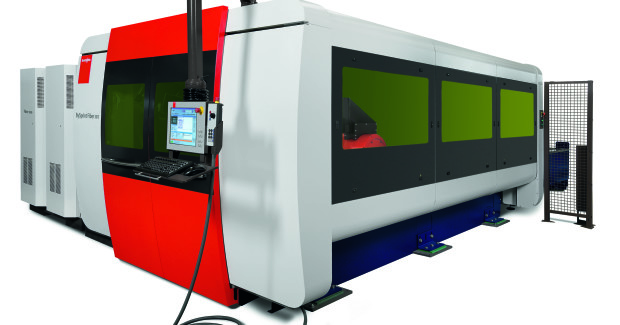

Bystronic also offers the BySprint Fiber 3015 and BySprint Fiber 4020 machines with a Fiber 6000 laser source, in addition to Fiber 2000, Fiber 3000 and Fiber 4000 laser sources. The higher power considerably increases the BySprint Fiber cutting speed in the thin-to-medium range of sheet metal thickness. A Fiber 6000 laser cuts 1/8 in stainless steel up to 70 percent faster than a Fiber 4000 laser. Its speed advantage is even more pronounced when compared to cutting the same material with a 6 kW CO2 laser, where the Fiber 6000 laser is three times faster. Depending on the type of material and the sheet thickness, parts output can be increased by up to 400 percent.

https://youtu.be/1k12KBjSaZg

The BySprint Fiber 4020 accommodates larger sheet sizes that deliver 78 percent additional cutting area and 78 percent larger part processing capability than the BySprint Fiber 3015. Equipped with the ByTrans Extended automated material loading and unloading system, the BySprint Fiber 3015 and BySprint Fiber 4020 can each generate highly productive and efficient job flows. With the Fiber 6000 laser’s high cutting speed, process reliability becomes more important than ever. For this reason, this 6 kW version of the BySprint Fiber is equipped with Cut Control to monitor the cutting process. Cut Control is also available as an option on the BySprint Fiber 3000 Laser and BySprint Fiber 4000 Laser systems.

The BySprint Fiber laser cutting system features a fully developed material parameter library for each material and thickness for optimum results from the very first experience. With dedicated service and laser application hotlines, Bystronic provides instant support for the BySprint Fiber, as well as a dedicated nationwide factory service network for local support. Regional service managers ensure local customer satisfaction.

Bystronic Inc., 200 Airport Road, Elgin, IL 60123, 847-214-0300, sales.us@bystronic.com, www.bystronicusa.com.