Power and Performance for All Fabricators

These fiber laser cutting systems offer flexible and economic laser processing across a variety of materials and thicknesses.

Posted: January 7, 2016

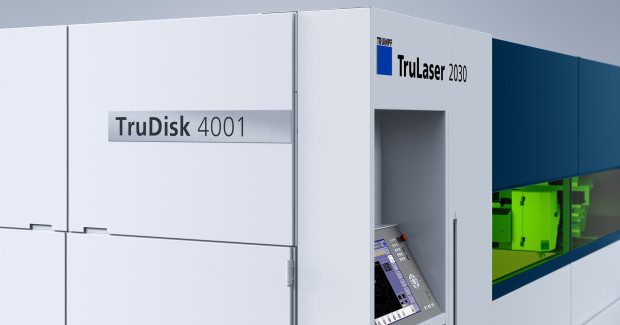

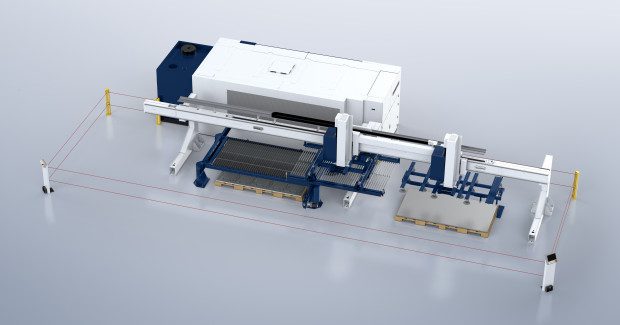

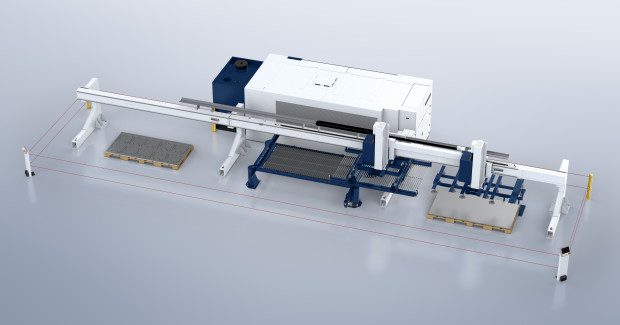

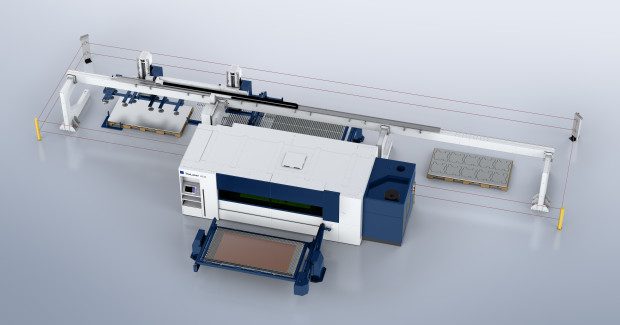

The TruLaser 2030 fiber laser cutting system with the new LiftMaster Shuttle from TRUMPF Inc. (Farmington, CT) is the most flexible automation system for loading and unloading available in this market segment. It offers flexible and economic laser processing across a variety of materials and thicknesses. With its energy-efficient, fully integrated 4kW TruDisk laser, the TruLaser 2030 fiber achieves optimum energy efficiency with minimal space requirements for a 60 in x 120 in working range. The machine is controlled by a user-friendly touch screen interface that graphically displays the program and all essential information – keeping operators in control, regardless of their experience level.

This system allows shops to run production with either the standard pallet changer or with the innovative LiftMaster Shuttle for complete lights-out production – ideal for overnight runs to gain additional capacity. This fast automation is available in many different configurations to match a customer’s layout and material flow in their shop perfectly. Its cost-efficient productivity and flexibility of use is suitable for job shops that run up to three shifts per day, as well as for first-time laser users looking to add laser cutting capabilities to their business. These and other features make this system the ideal choice for fabricators in need of productivity and process reliability at competitive investment and operating costs.

TRUMPF also offers the TruLaser 5030 fiber, the first 2D laser cutting machine available with an 8 kW TruDisk laser that significantly boosts productivity when processing medium and thick sheet metal. As a highly productive, universal machine, the TruLaser 5030 fiber is able to process complex contours and thin sheets while keeping the cost per part to a minimum. Its BrightLine fiber, CoolLine, and enhanced PierceLine functions guarantee high-quality laser processing in thicker materials as well. CoolLine, a new feature for solid-state lasers, stabilizes the cutting process in steel by use of targeted cooling. This results in greater material tolerance while enabling more intricate material contours and a tighter layout of parts. The new PierceLine function with improved piercing capabilities enables the laser to process smaller contours while significantly boosting speed.

Smart Collision Prevention and the Drop&Cut options further increase the efficiency and reliability of laser processing for TRUMPF 2D laser cutting machines. With Smart Collision Prevention, the risk of collisions during laser cutting is minimized. The function analyzes the cutting process to determine where cut parts are likely to tip and adjusts the processing strategy to accommodate. This can be achieved most often without adding microjoints to the part and can significantly reduce downtime caused by collisions. When coupled with the smart nozzle function with integrated nozzle inspection feature and the enhanced PierceLine piercing process, Smart Collision Prevention assures maximum process reliability for the TruLaser 5030 fiber. This substantially expands machine capacity while reducing the need for consumables.

The Drop&Cut feature aids in cost-effective production and enables operators to easily use part skeletons for additional production. Operators are provided with a live image of the machine’s interior on the control unit’s user interface. From the control unit, the operator simply clicks or taps the screen to drag the programmed contour to the desired location on the projected sheet and initiates the cut. With the new TruLaser 5030 fiber, the process is conveniently managed from a new and ergonomic 19 in control panel that can be adjusted to any height. Smart Collision Prevention and Drop&Cut is available on the TruLaser 5030 fiber, as well as new TruLaser Series 3000 and 5000 laser machines.

TRUMPF also offers the TruLaser Cell 3000, a 5-axis laser machine for cost-efficient fine cutting and precision welding of small or medium sized 2D or 3D components. The highly precise laser system is the ideal solution for processing a wide range of applications, from one-off prototypes to high-volume production. With solid-state laser options, available with up to 8 kW of laser power, the TruLaser Cell 3000 is also well-suited for processing nonferrous metals. It is an attractive solution for job shops, automotive subcontractors, medical device manufacturers and others.

Processing metals is simple with the optional variable beam formation that allows for both focus position and spot diameter adjustments. It is also possible to expand the diameter of the focus. This enables fabricators to cut materials of different thicknesses or switch between welding and cutting applications without changing the focusing optics. The TruLaser Cell 3000 compact footprint, modular design and large selection of options enables fabricators to choose the solution that best fits within their production environment.

TRUMPF also recently introduced the new TruMark 5050, a fiber marking laser with an adjustable pulse length that is flexible and able to process a diverse range of materials with impressive results. High beam quality and high average power make the TruMark 5050 the ideal laser for engraving. Short pulses enable very precise energy input for highly accurate marking while longer pulse durations increase the productivity of the system. It is also possible to increase productivity with an optional dual head system. Using two scanners, two parts can be processed simultaneously.

Operating in the infrared range (1,062 nm) and with an adjustable pulse duration from 7 ns to 500 ns, the TruMark 5050 is able to cover a broad spectrum of diverse applications across many industries, including medical, electronics, automotive and precision machining. It economically processes conventional metals such as mild steel, stainless steel, aluminum and copper, and produces high-quality results when deep engraving these materials. The combination of high average power, differing pulse shapes and variable pulse duration also makes the TruMark 5050 attractive for micro-processing, such as cutting films and foils. With a compact processing head and plug-and-play connections, this machine can be integrated into new and existing manufacturing systems without difficulty. The laser is also protected against dust and is water resistant, making it ideally suited for an industrial environment.

TRUMPF Inc., Farmington Industrial Park, 111 Hyde Road, Farmington, CT 06032, 860-255-6104, www.us.trumpf.com.