Laser Cutting in Heavy Plate Fabrication

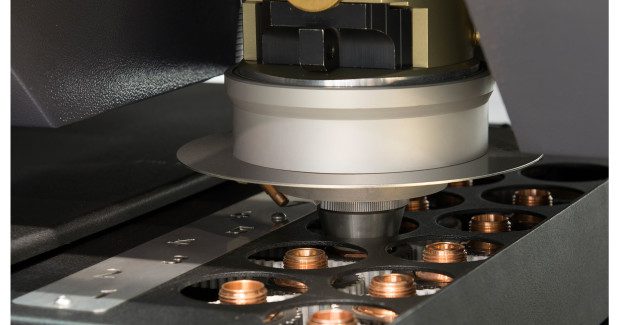

The large table Impuls 6020 CO2 laser cutting system from LVD Strippit has an optional nozzle changer with storage for ten nozzles to reduce piercing times and increase overall throughput.

Posted: February 29, 2016

LVD Company nv | Strippit, Inc. (Akron, NY) offers an optional nozzle changer on its large table capacity Impuls 6020 CO2 laser cutting systems for heavy plate fabrication. Featuring storage for ten nozzles, the option brings greater autonomy, reduces piercing times and increases overall throughput on large table capacity laser systems. As materials and thickness change throughout the production day, the machine will select the right nozzle for each and every job. Requiring no operator intervention, the nozzle changer reduces downtime, by quickly performing nozzle changes including cleaning the nozzle and checking the nozzle alignment.

Strippit, Inc., 12975 Clarence Center Road, Akron, NY 14001, 716-542-4511, info@strippit.com, www.lvdgroup.com.