AM Opportunities in the Metals Industry

Shops cannot ignore how additive manufacturing may disrupt parts of the metals supply chain.

Posted: February 22, 2016

According to a report commissioned by the Metals Service Center Institute (MSCI; Rolling Meadows, IL), 3D printing and additive manufacturing (AM) has the potential to disrupt parts of the metals supply chain in the coming decades.

AM today is not some far-off manufacturing process that companies can afford to ignore. An estimated $3 billion industry in 2013 became a $4 billion plus industry in 2014, according to research cited in the report. Most conservative projections show compound annual growth rates for the global AM industry ranging from 18 percent to 34 percent into 2020, and annual revenue from $7 billion to more than $23 billion by that same year.

“Manufacturing as we know it is changing,” said M. Robert Weidner, III, the president and chief executive officer of MSCI. “Product customization and value-add as a result of additive manufacturing could be a game changer — it could bring huge challenges for the metals industry as well as potential opportunities.”

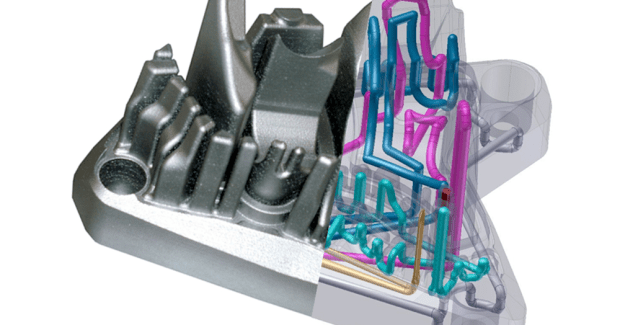

According to the report, AM changes the fundamental nature of product design. The design and manufacturing effort can be directed for optimal efficiency, cost and functionality for a metal part. For some companies, this might reduce assembly steps or eliminate tooling, leading to significant cost savings. Stratasys, Ltd. (Eden Prairie, MN), a large manufacturer of 3D printing and AM equipment, surveyed 700 product designers, engineers and business executives, and 84 percent of respondents ranked metal as the top item in the list of materials they’d like to see addressed further by the process.

Another challenge, and opportunity, is the unpredictability of 3D printing powder quality. Developing high grade metal printing powders and establishing quality controls is a rapidly growing field with a great deal of room for innovation.

MSCI members can view the online report here.

Founded in 1909, MSCI is a non-profit association serving the metals industry. It serves members in more than 1,500 locations in the U.S., Canada, Mexico and throughout the world. A study done by them shows the American metals industry accounts for nearly 2.5 million jobs and contributes more than $552 billion, or over 3.5 percent, of the nation’s gross domestic product.