Universal Multi-Functional Vacuum System

The Multi-Power Vac workholding system from Mitee-Bite can hold one to four small parts or one large part for machining.

Posted: February 4, 2016

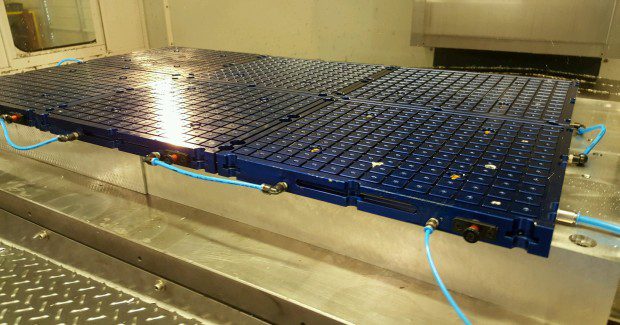

Mitee-Bite Products LLC (Center Ossipee, NH) offers the Multi-Power Vac workholding system that is possibly the most universal multi-functional vacuum system in today’s market. This 14 in x 16 in vacuum workholding system can be powered with a vacuum generator (shop air) or vacuum pumps and has a textured surface to create additional holding force through friction. Four vacuum ports allow the user to hold one to four small parts or one large part (ports can be plugged). The grid plate is tapped with M6 threads that allow multiple workholding solutions. Six oversized steel washers are machined below the bottom surface to allow the unit to be used for grinding operations on a magnetic chuck. Multiple vacuum generators can be used on each pallet if additional cfm is desired, and multiple pallets can operate from a single vacuum generator. A coolant trap may be necessary when using external vacuum source (the trap is sold separately).

Mitee-Bite has also added a cost effective, simple Quick Change Receiver System that allows for the rapid change-out and precise location of small fixture pallets. The Quick Change Receiver is designed to accept any of the company’s current pallets, as well as a special Blank pallet. The receiver mounts on T-slot tables, tombstones, sub-plates and aluminum T-Slot Grid Plates. Special washers and mounting clamps are provided with the system. All hardware is recessed to allow the receiver to be skim cut to perfectly match the table. The Receiver is furnished with diamond and taper pins and hardened liner bushings. The Blank pallet is fastened to the receiver with the Loc-Down® System – two turns of the Loc-Down releases the pallet. There is 100 lb of force for every ft-lb of torque. The Loc-Down is not removed from the receiver, making lost cumbersome fasteners are a thing of the past. There is no protruding fastener above the surface of the pallet to interfere with tooling. The result is high precision for a low cost.

Mitee-Bite also offers OK-VISE® low-profile clamps that function on the principle that when tightened down they expand, simultaneously pressing the workpieces against the guide and preventing any possibility of play. These clamps are designed to fit between the workpieces and take very little space on the fastening base. Small in size, yet possessing an excellent clamping force up to 33,000 lb, these clamps guarantee a holding capacity which clearly exceeds the load imposed by machining forces. The single wedge clamps keep the workpieces steadily in place, not allowing upward or downward movement. The double-wedge clamps generate a pull-down action pressing the workpieces towards the fixture base. Single-wedge clamps are also available with extended jaws that can be machined to suit the geometry of the workpiece. On special models, a self-adjusting steel ball is helpful when clamping castings and workpieces of irregular shape. Jaws tapped with M5 threads for socket head screws allow for custom “soft jaw” applications.

Mitee-Bite Products LLC, 340 Route 16B, PO Box 430, Center Ossipee, NH 03814, 603-539-4538, Fax: 603-539-2183, www.mitee-bite.com.