Upgrade Easily to Smaller Lot Sizes

These quick change chucks and clamping systems from SCHUNK make full use of the flexibility that machine tools now offer so that the same part cost can be achieved in much smaller production runs.

Posted: February 4, 2016

In manufacturing, it is always vital to keep costs down. For this reason, shops must focus on three cost drivers that they can control: lot size, set-up and changeover times, and machine costs. Analyzing how smaller lot sizes affect the costs of parts is important, because set-up changes and changeover times represent opportunities to keep machines running and avoid costly downtime. As machine tools grow more sophisticated with combined functions and capabilities, they become more expensive to invest in and to operate, which makes the need to keep them running even more crucial. Smaller lot sizes can increase the cost per part on these machines unless the right workholding is used for faster set-up changes and quicker changeover times.

Workholding must be updated to make full use of the flexibility that machine tools now offer so that the same part cost can be achieved in much smaller production runs. Most machines come equipped with basic conventional lathe chucks. One essential upgrade should be to move to a quick change chuck, such as the ROTA NCX from SCHUNK, Inc. (Morrisville, NC), a power lathe chuck with quick jaw change system that boasts a large through-hole and has been optimized with reduced weight. Upgrading to the ROTA NCX is more straightforward than ever as it fits perfectly on machines that are equipped with short stroke cylinders. It can replace conventional lathe chucks easily, even as easy as using the internal parts of an existing chuck such as the same draw tube adapter, adapter plate, and retaining ring.

With the ROTA NCX, a jaw set can be changed out with a repeat accuracy of 0.02 mm while decreasing set up time by up to 80 percent. A shop can get the most potential out of their machine and easily increase machine uptime easily. The ROTA NCX also ensures maximum operational safety with its jaw locking system.

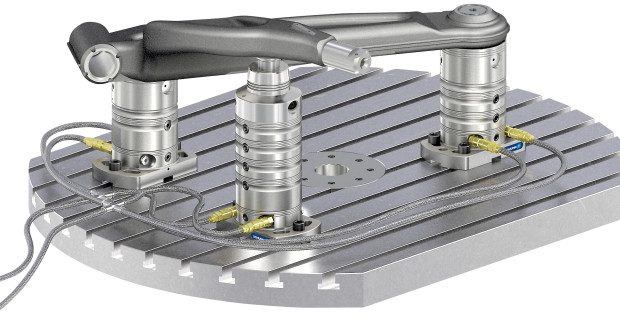

SCHUNK also offers the world’s first modular system for direct workpiece clamping that is perfect for applications requiring minimal batch sizes, high precision requirements and complex geometries. The modular system consists of VERO-S WDB base modules for the machine table, VERO-S WDN clamping modules (ø 99 mm), and freely combinable VERO-S WDS stacking modules. The latter have a standardized height of 30 mm and 50 mm to allow fine graduations of 10 mm in the height of the clamping columns starting at a height of 80 mm. The connections between the single modules are designed for high machining parameters, with a high pull-in force of up to 25,000 N. To ensure distortion-free workholding, height differences can be compensated by a steplessly adjustable, hydraulically clamped VERO-S WDA compensation element.

https://youtu.be/7_i5dwoAV34

Modular clamping columns enable direct clamping of molding plates, free-form parts, and other workpieces on the machine table within seconds, without additional clamping devices or interfering contours. The clamping pillars guarantee collision-free processes, a defined clamping situation, and a reliable simulation of the machining. In addition, changes in the workpiece can be implemented quickly due to the high precision of this clamping solution.

All interfaces feature scope-free taper centering, which ensures a repeat accuracy of < 0.005 mm between the single components. An integrated air feed-through allows actuation of the clamping modules and monitoring of the presence of a workpiece. The workpieces themselves remain securely clamped even if the pressure in the air system should suddenly drop. A pneumatic system pressure of 6 bar is sufficient for opening the clamping modules. For a longer life and increased process reliability, all functional parts such as the base body and slide assemblies are made of hardened stainless steel, are absolutely corrosion-resistant, and very easy to clean.

The SCHUNK quick change pallets system has taken quick change workholding to a new level. The VERO-S SPM-138 diaphragm clamping system allows a shop to machine the contour of their workpiece into the SPM unit. When the VERO-S module is engaged with the Turbo function, the SPM-138 unit clamps evenly around the outside of the part. VERO-S SPM Plus 138 can clamp workpiece sizes of Ø 36 mm to Ø 125 mm, although the workpieces do not have to be round. The SPM unit generates clamping forces up to 50 kN. The VERO-S is paving the way to more precision, efficiency, process reliability, and set up reduction in metal cutting and CMM inspection.

The same VERO-S plus 138 module clamps small workpieces with the SPM Plus 138 top plate, as well as pallets, clamping stations, existing fixtures, and tombstones with one or more clamping pins. The radial aligned clamping slides of the quick-change pallet system pulls in the clamping pin and locks it. This action retracts the Diaphragm top plate to hold the work piece with up to 50 kN of force with a repeat accuracy of at least 5 microns (0.0002 in). The VERO-S is completely compatible and interchangeable with SCHUNK’s previous pallet system and the clamping pins work universally across the new line. Workpieces can be transferred from machine to machine, or to a CMM accurately and seamlessly. Hardened stainless steel is used for all the functional components of the VERO-S, such as base body, clamping pin, and clamping slide. This increases the modules’ life and reliability, and reduces maintenance.

The maintenance-free module is completely sealed and protected against the penetration of chips, dust, and coolant. Integrated into the standard module is an air purge connection that can also be used for part recognition. The position of the clamping slide can also be monitored via an air purge monitoring system. Each module is compatible for automated loading out of the box. Since the module is equipped with bottom and lateral air connections, it is completely flexible in its mounting.

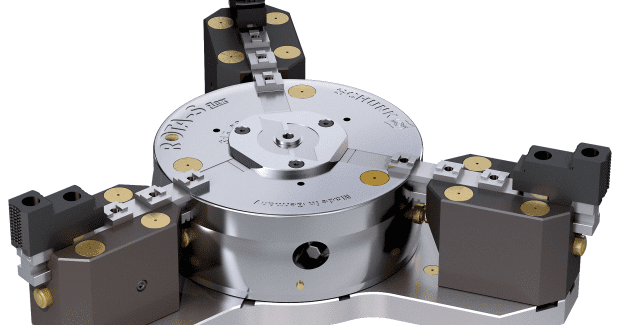

To maximize the potential of milling and turning machines, SCHUNK offers the highly flexible ROTA-S flex manual chuck for machining a wide variety of workpieces. The ROTA-S flex has all the same beneficial features as the tested and proven ROTA-S plus in addition to extended guideways, transforming it into a large, versatile, lightweight chuck. Its weight is approximately 60 percent less than that of a conventional chuck with the same capacity. It has an identical table load so that much heavier workpieces can be machined. Due to its low profile, the chuck allows plenty of space for the workpiece and tools.

https://youtu.be/pfYT139JOPM

For machining smaller workpieces, the extended guideways can easily be disassembled, improving workpiece accessibility compared to conventional large chucks. A special lubrication system ensures permanently high clamping forces for both versions. The chuck also boasts seals that prevent chips and dust from entering. The ROTA-S flex can be easily assembled on a machine table, and by using the optimized quick-change jaw system, retrofitting can be quickly done. The chuck clamps small parts as reliably as large ones, ensuring operator safety. The Rota-S flex is available in a variety of sizes and can be combined with numerous chuck jaws from the 1,200 types of the world’s largest standard chuck jaw program from SCHUNK.

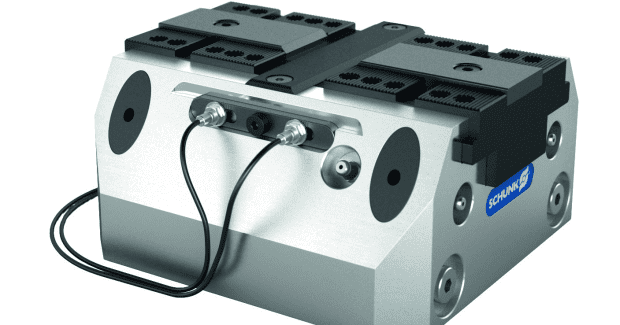

The TANDEM KSP plus clamping force block from SCHUNK is setting new standards in automated manufacturing. For the first time ever, a standardized clamping force block provides for flexible monitoring along the whole jaw stroke. Whether using ID or OD clamping, the positions “opened” or “clamped” for any base jaw position can be adjusted. Monitoring is done via two inductive proximity switches that are integrated in two special recesses in the base jaws. The system is sealed and resistant against dirt. Since the signal can be directly processed in the machine control unit, the flexible queried clamping force blocks can be quickly and easily integrated into existing machines.

The compact clamping block has a high clamping force and exact precision. Its one-piece, rigid base body, the wedge hook kinematics, and the long ground jaw guidance provide for concentrated clamping forces of up to 55 kN. Excellent repeat accuracy of up to 0.01 mm ensures exact results that are suitable for demanding milling operations at a high metal removal rate, high cycle times, and minimum tolerances. Due to the two integrated jaw interfaces, top jaws with tongue and groove and jaws with a fine serration can be used. The clamping force blocks are also available with an optional jaw quick-change system. The optimized outside contour and minimum gaps prevent the build-up of dust pockets, chips, or dust from penetrating the clamping block. A special fitting screw ensures that the clamping block can be exchanged at the highest repeat accuracy.

SCHUNK, Inc., 211 Kitty Hawk Drive, Morrisville, NC 27560, 919-572-2818, Fax: 919-572-2818, info@us.schunk.com, www.schunk.com.